High-flow liquid medium combined supply system

A liquid medium and supply system technology, which is applied in aerospace engine tests and aviation fields, can solve the problem that the booster system cannot automatically adjust the supply pressure, and achieve the effect of flow balance and stable end pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

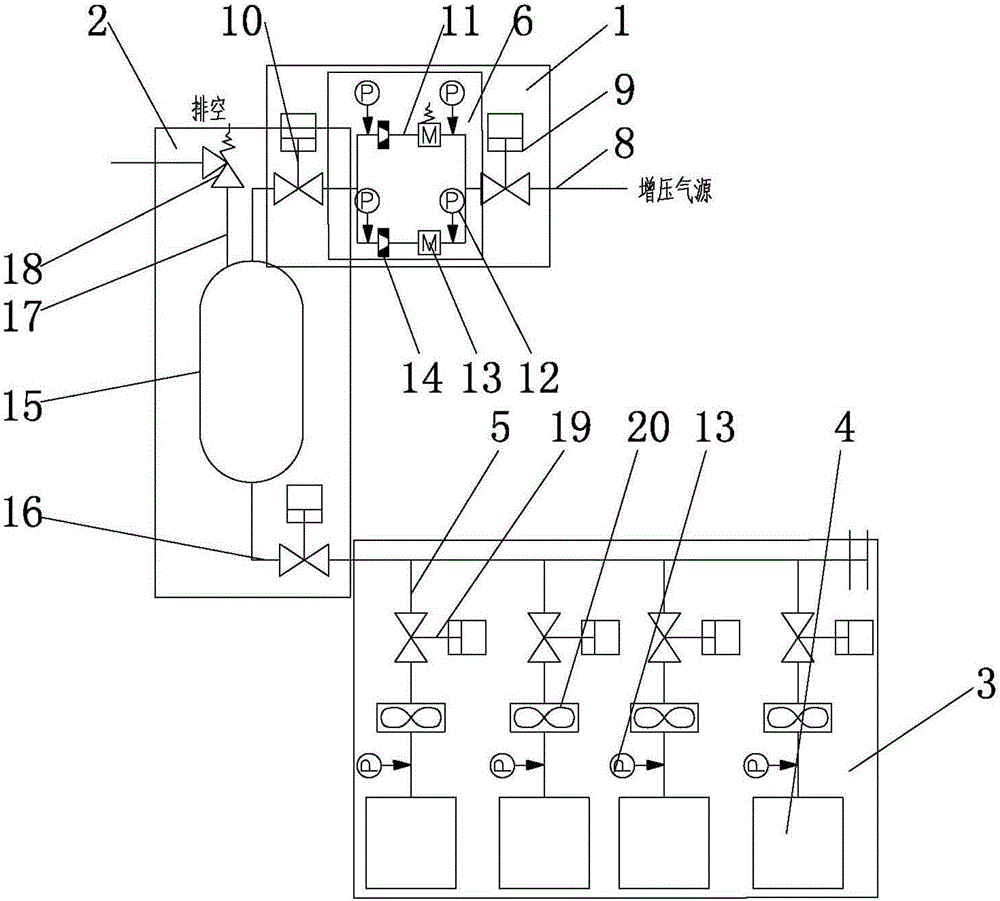

[0017] Such as figure 1 As shown, the present invention provides a large flow liquid medium combination supply system,

[0018] Including a pressurization unit 1, a storage unit 2 and a supply unit 3;

[0019] The pressurization unit 1 communicates with the storage unit 2 for pressurizing the storage unit; the storage unit 2 is used for storing media; the storage unit 2 communicates with the supply unit 3 for providing media to multiple terminals 4;

[0020] The supply unit 3 is composed of more than two branch pipelines 5; the connecting pipelines between every two branch pipelines 5 have the same length, and each branch pipeline 5 has the same length.

[0021] Specifically, the booster unit 1 includes a pressure closed-loop regulator 6, a first pneumatic valve 9, a second pneumatic valve 10, and a booster pipeline 8; the inlet of the booster pipeline 8 communicates with the booster gas source, and the outlet communicates with the The unit 2 is connected; the booster pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com