Capacitance sensor-based strain test device of magnetic shape memory alloy

A capacitive sensor, memory alloy technology, applied in electromagnetic measurement devices, electric/magnetic solid deformation measurement, etc., can solve problems such as the influence of strong magnetic fields around magnetic memory alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

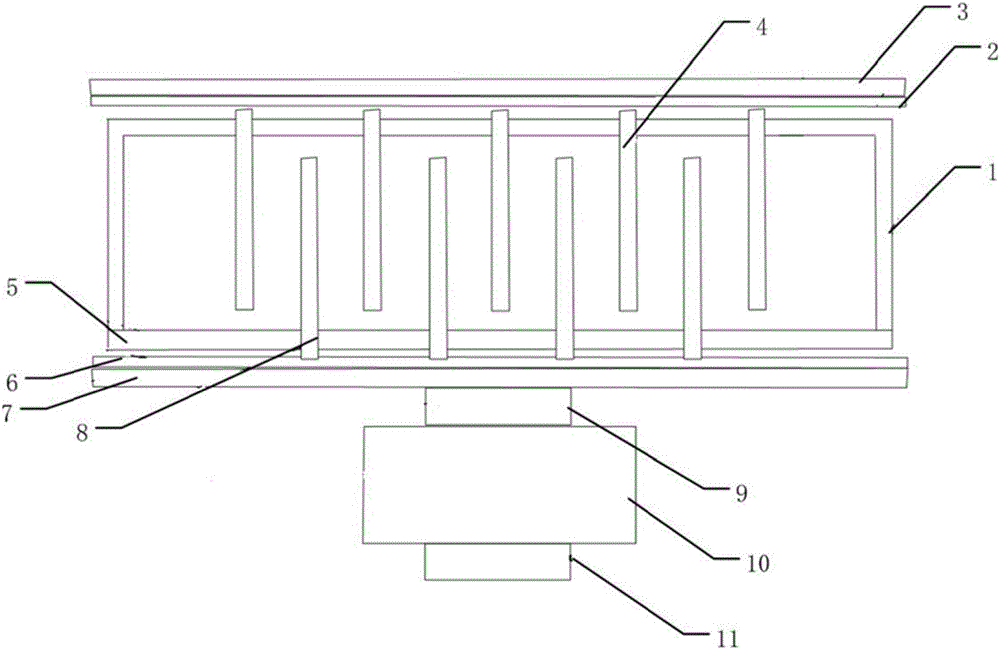

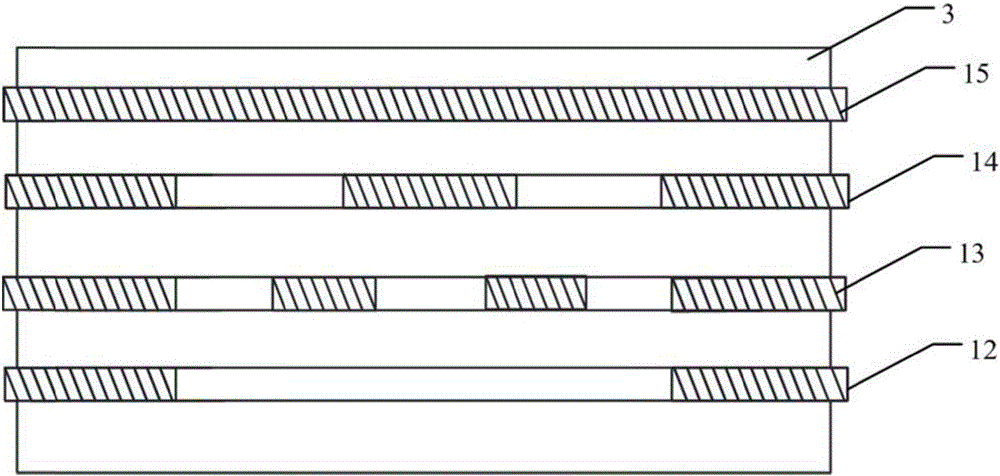

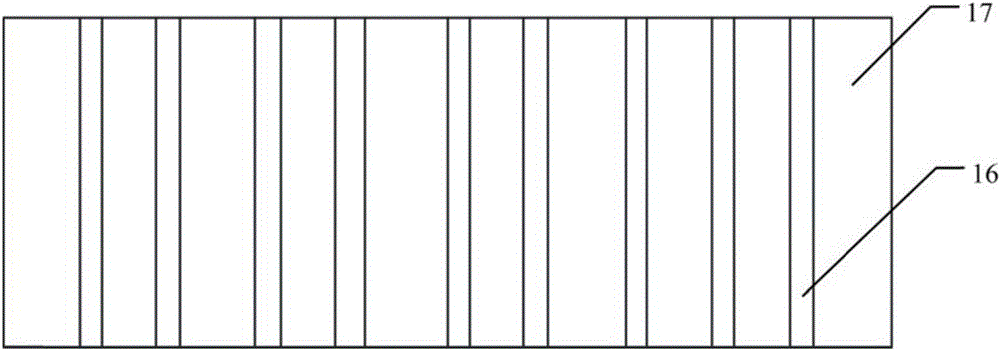

[0036] The invention provides a strain testing device for magnetically controlled shape memory alloys based on capacitive sensors. By converting the small deformations such as the magnetically induced strain of the magnetically controlled memory alloys into changes in the area of the parallel plates of the parallel plate capacitor probe, the displacement The amount is converted into a change in capacitance value. Effectively solve the technical problem that the magnetic memory alloy is affected by the surrounding strong magnetic field, thereby improving its detection accuracy.

[0037] see Figure 1 to Figure 3 , a strain testing device based on a capacitive sensor-based magnetically controlled shape memory alloy in the present invention, comprising: a capacitive probe, a gear amplification mechanism 10, an input mechanism 11 and an output mechanism 9;

[0038] The gear amplification mechanism 10 includes N gear sets, and each gear set is composed of two gears with differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com