A high-pressure gas detection joint for micro-diameter thin-walled tubes of heat exchangers

A technology of high-pressure gas and detection joints, which is applied in the field of aerospace science to achieve the effects of convenient assembly and disassembly, improved detection quality, and easy observation of detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

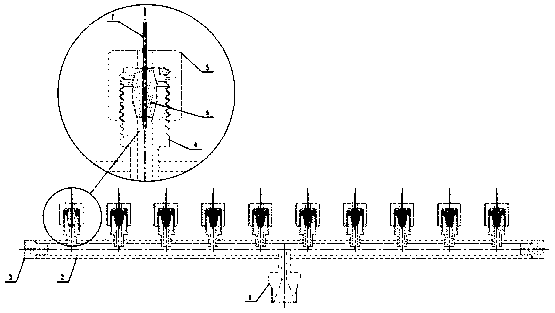

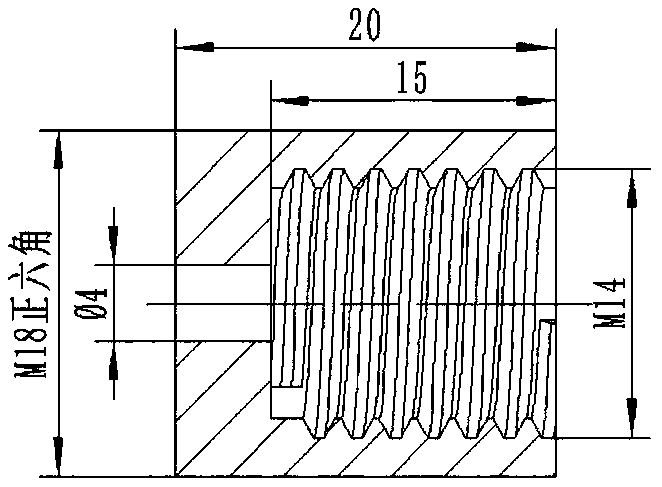

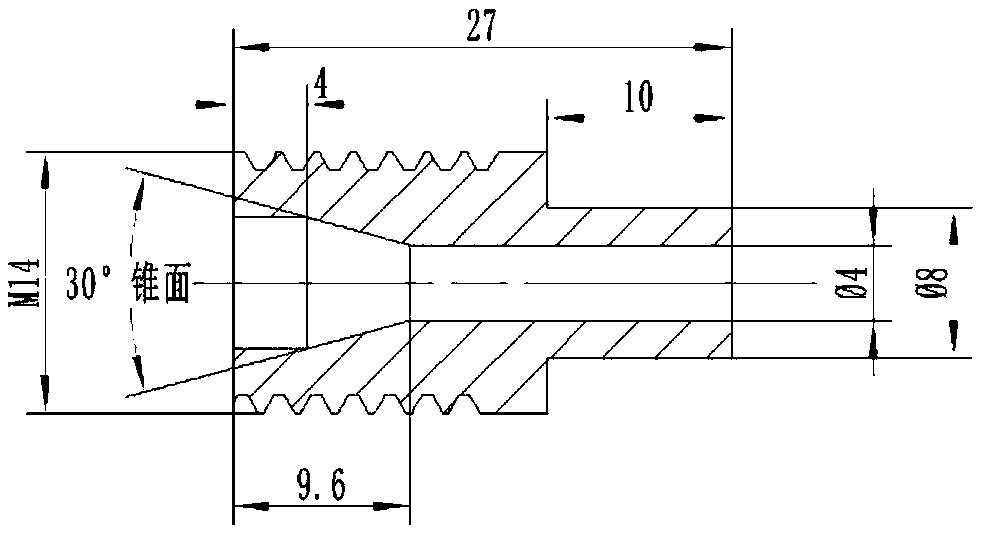

[0033] See Figure 1-Figure 7 , the present invention is a high-pressure gas detection joint for micro-diameter thin-walled tubes of heat exchangers, which mainly includes a first-level joint 1, a shunt pipe 2, a plug 3, a second-level joint 4, a second-level joint nut 5, and a sealing joint 6 parts; the positional relationship between them is: the first-level joint 1, the second-level joint 4 and the plug 3 are respectively assembled and welded to the shunt pipe 2; the outer conical surface of the sealing joint 6 and the inner conical surface of the second-level joint 4 Contact installation, fixed by the thread fit of the secondary joint 4 and the secondary joint nut 5; at the same time, the micro-diameter thin-walled tube 7 is inserted into the inner hole of the sealing joint 6, and the axial extrusion force of the conical surface of the secondary joint 4 to fix.

[0034] When the high-pressure gas detection joint is working, firstly, the conical surface of the primary join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com