Engine noise source identification method

An identification method and engine technology, applied in engine testing, machine/structural component testing, measurement of ultrasonic/sonic/infrasonic waves, etc., can solve the problem of large subjective influence, inability to obtain the contribution of noise sources, and inability to identify noise sources. Satisfy the overall accuracy and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In view of the above problems, the purpose of the present invention is to overcome the deficiencies in the prior art, by constructing a hierarchical analysis tree, comprehensively considering the influence of different speed conditions, different measuring point positions and different noise frequency bands on the noise source identification results, and proposing by improving the AHP method An objective evaluation method to determine the pairwise comparison results is proposed, which eliminates the influence of the evaluator's subjective factors and improves the accuracy of noise source identification. Technical scheme of the present invention is as follows:

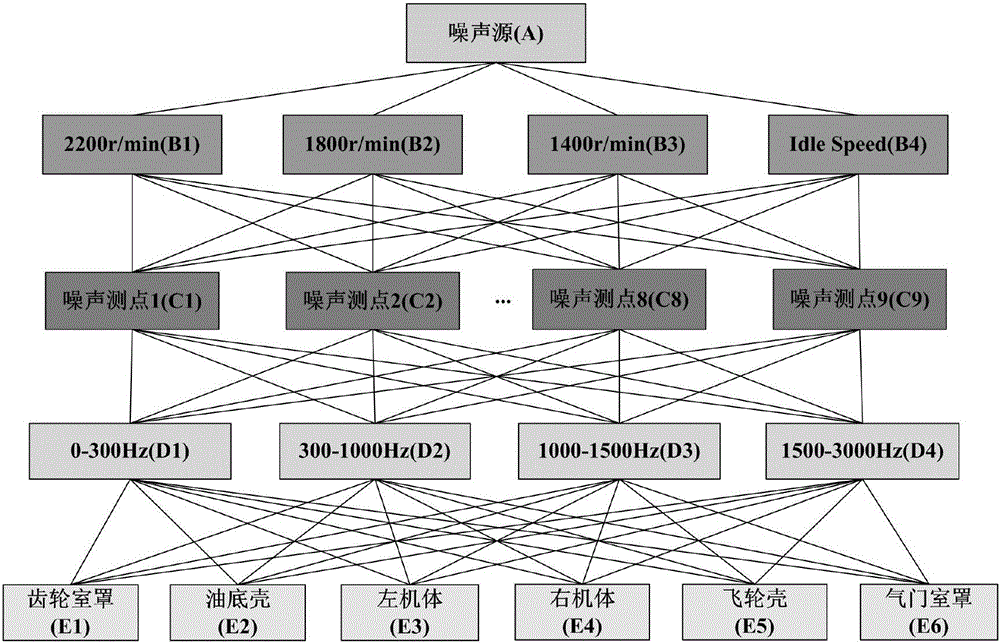

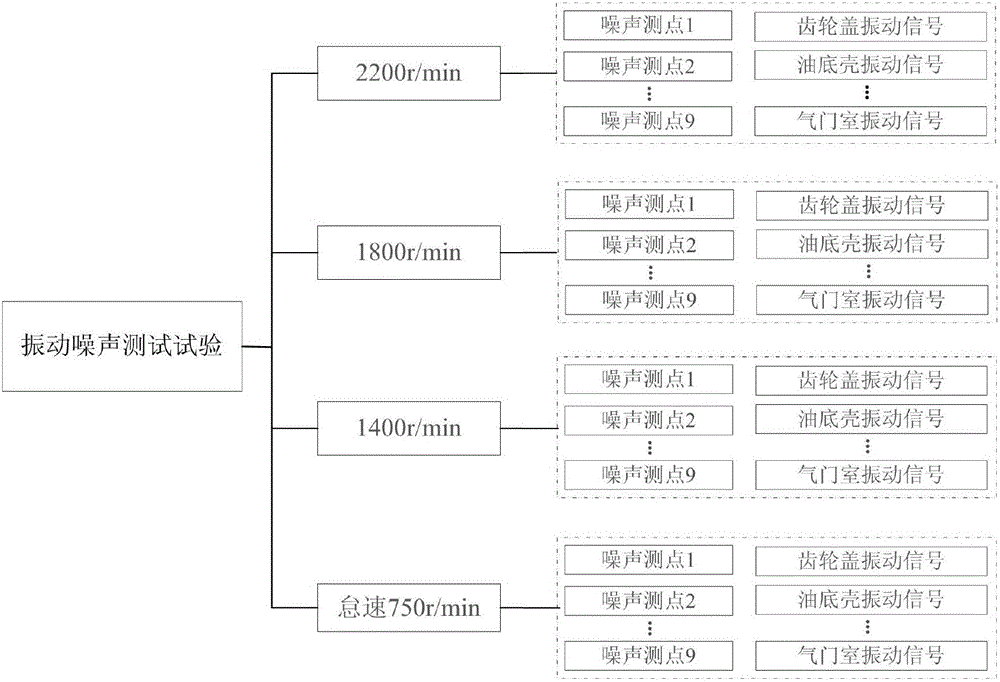

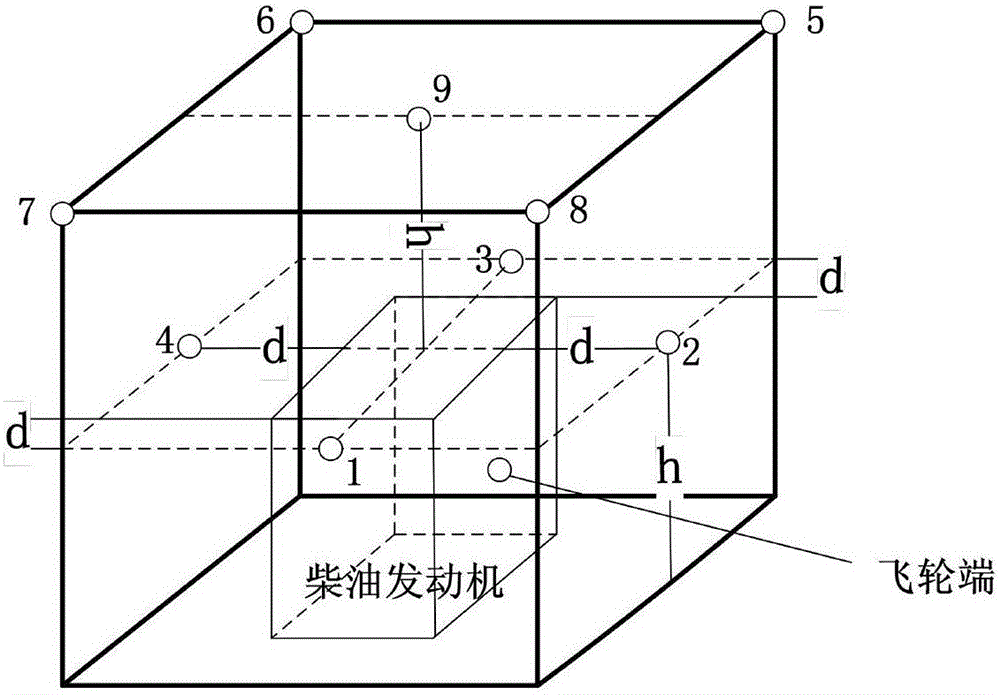

[0018] (1) First construct the hierarchical analysis tree of noise diagnosis, such as figure 1 As shown, it includes speed layer, noise measurement point layer, frequency band layer, and component layer. Each layer includes different elements. First, calculate the contribution of different components to different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com