An in-situ loading device based on scanning electron microscope

A technology of scanning electron microscopy and in-situ loading, which is applied in the direction of scanning probe technology and instruments, can solve the problems that there is no supporting loading device for scanning electron microscope, achieve large load and high frequency fatigue loading, and improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

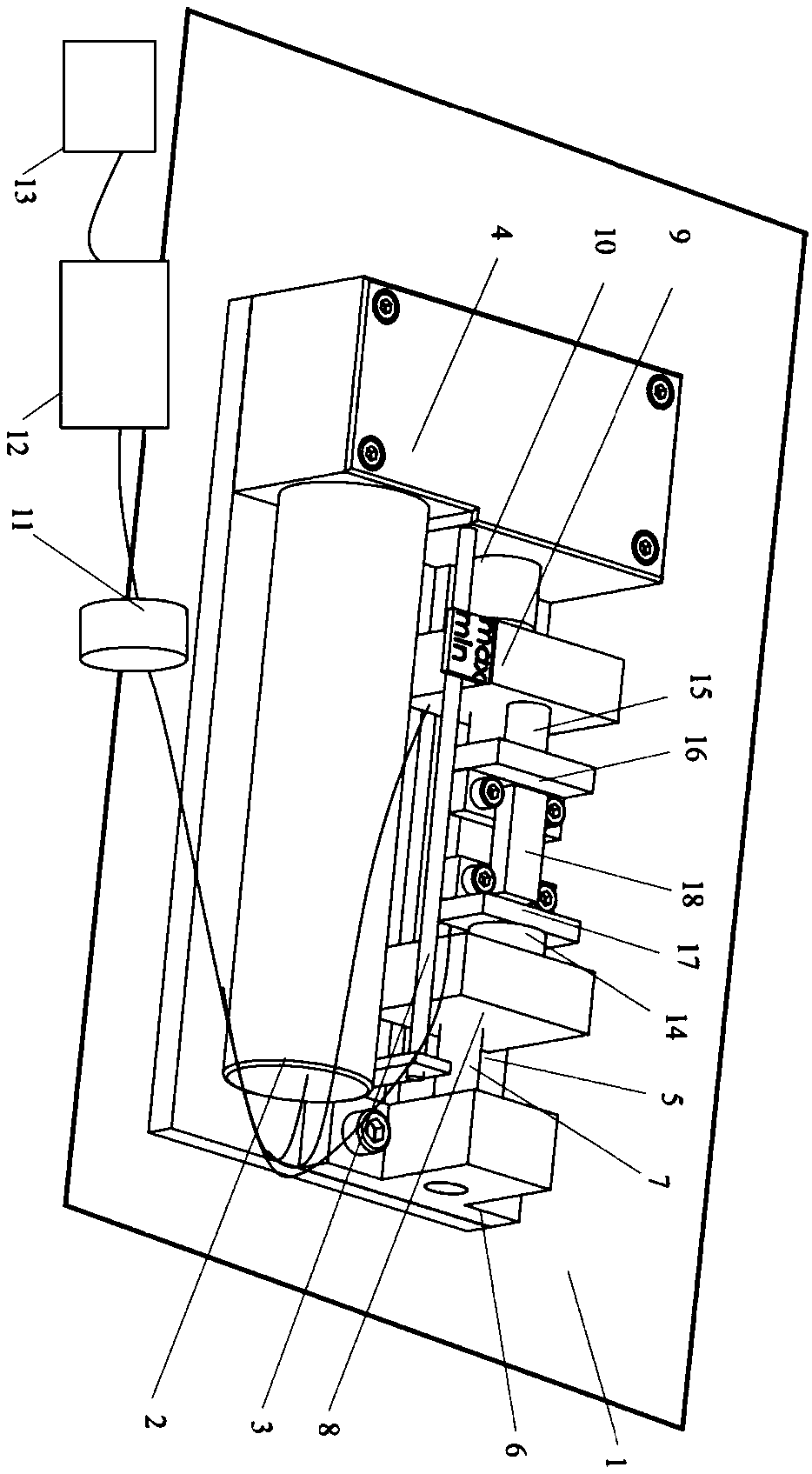

[0021] Such as figure 1 As shown, an in-situ loading device based on a scanning electron microscope according to the present invention includes a fixed plate 1, a motor 2, a grating displacement meter 3, a transmission device 4, a slider guide rail 5, a bearing seat 6, a bidirectional Ball screw 7, first adapter block 8, second adapter block 9, coupling 10, control box 11, computer 12, sealing flange with transmission line 13, force sensor 14, combined piezoelectric ceramics 15, The first clamping device 16, the second clamping device 17 and the test piece 18, and all the components are placed on the fixed plate 1 except the control box 11, the computer 12, and the sealing flange 13 with transmission lines.

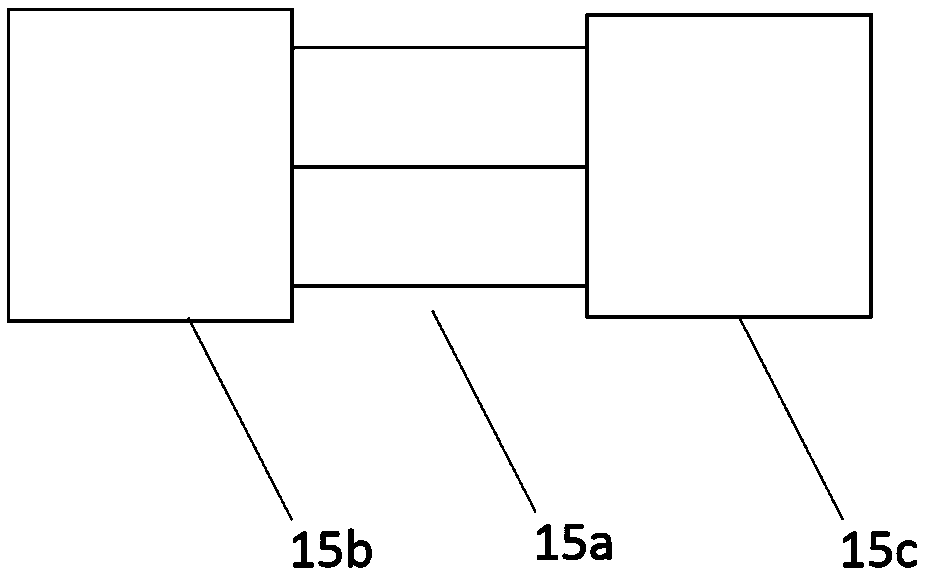

[0022] The motor 2 is connected to the transmission device 4 through a keyway, and the transmission device 4 is connected to the bidirectional ball screw 7 with a nut through a coupling 10 . Such as figure 2 As shown, the combined piezoelectric ceramic 15 is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com