Exposure equipment and exposure method

An exposure method and equipment technology, applied in microlithography exposure equipment, optomechanical equipment, photolithography process exposure devices, etc., can solve problems such as reducing production efficiency, increasing manufacturing costs, etc., to improve productivity and save masks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

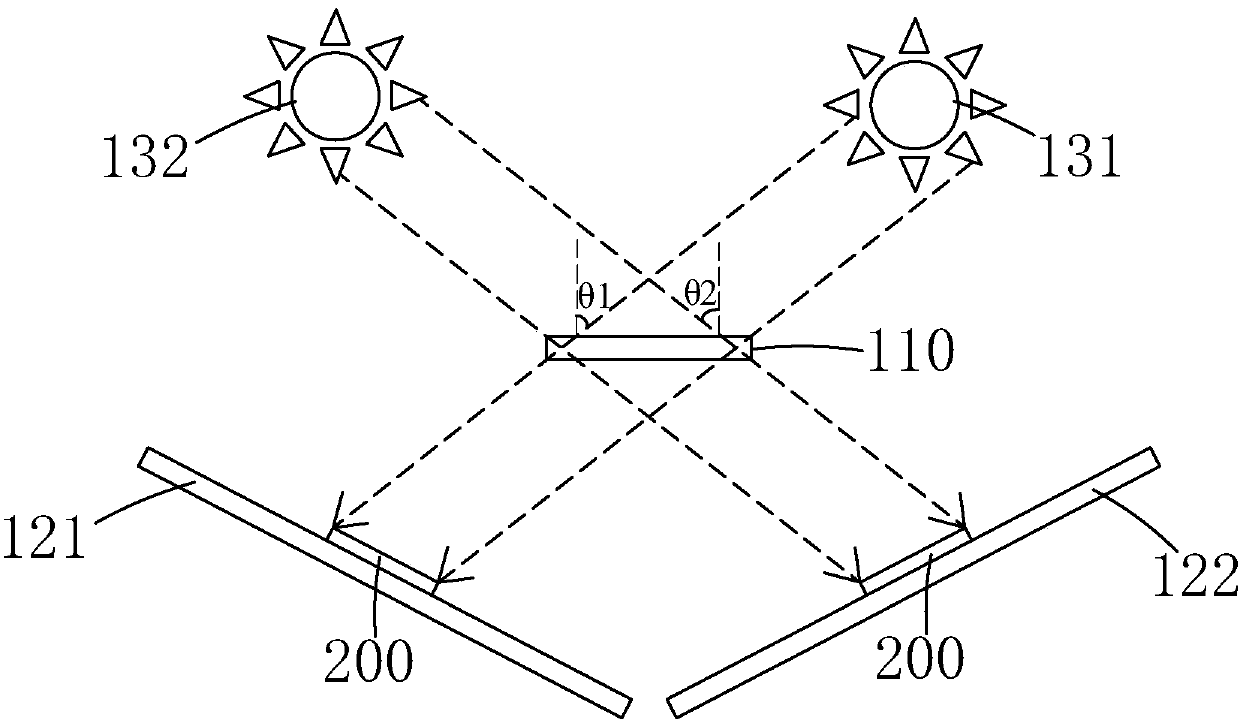

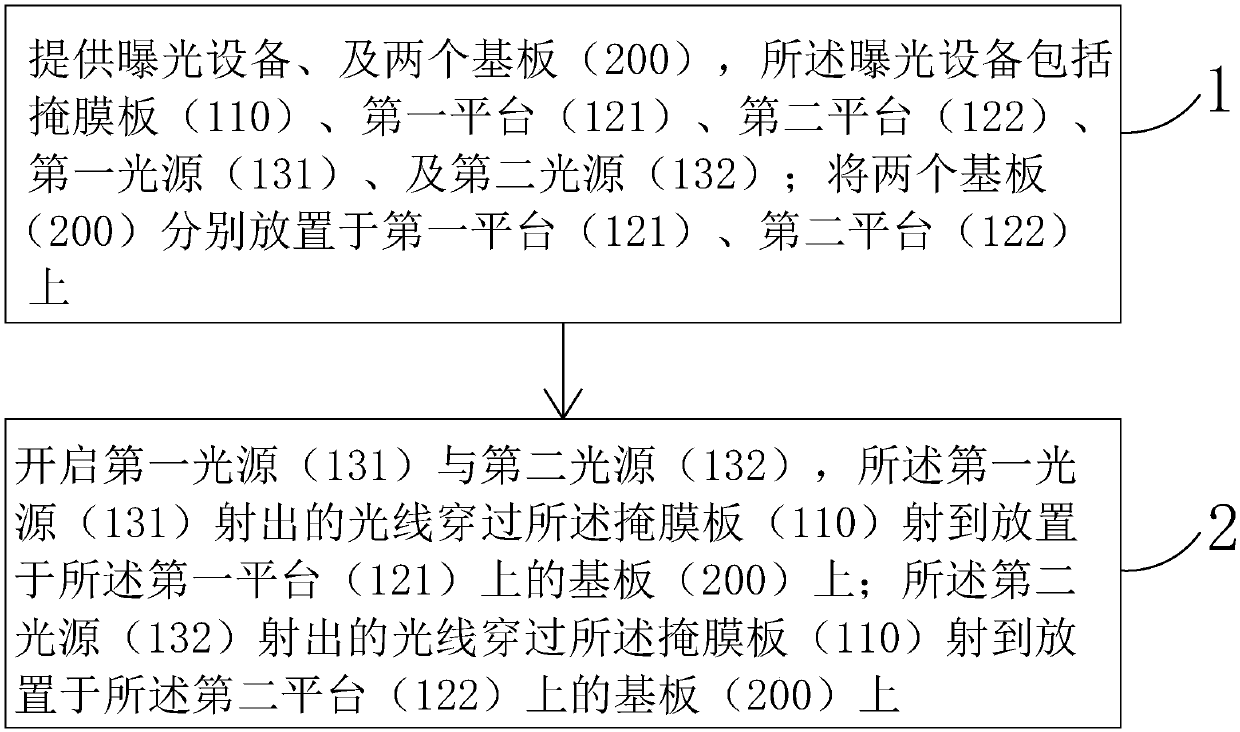

[0037] see figure 2 , the present invention firstly provides an exposure device, including a mask 110, a first platform 121 arranged on the left side of the mask 110, and a second platform 122 arranged on the right side of the mask 110. , the first light source 131 arranged on the upper right side of the mask 110, the second light source 132 arranged on the upper left side of the mask 110, and the mask 110, the first platform 121, the second The second platform 122 , the first light source 131 , and the exposure chamber of the second light source 132 (not shown).

[0038] Wherein, the first platform 121 and the second platform 122 are both used to carry the substrate 200; the light emitted by the first light source 131 passes through the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com