Fabrication method of GaN-based composite substrate

A technology for composite substrates and transfer substrates, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc. Effects of adhesion, improved crystal quality, improved device performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035]The preparation method of the present invention can be used to prepare a GaN-based composite substrate with a nitrogen polarity facing up, or a GaN-based composite substrate with a gallium polarity facing up.

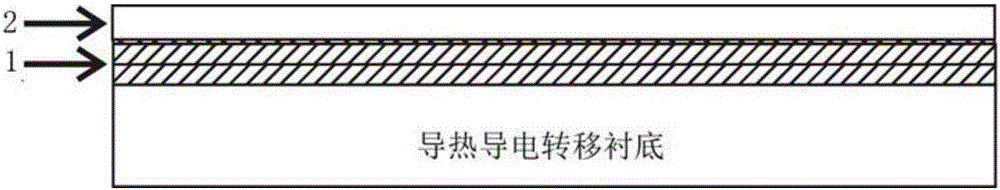

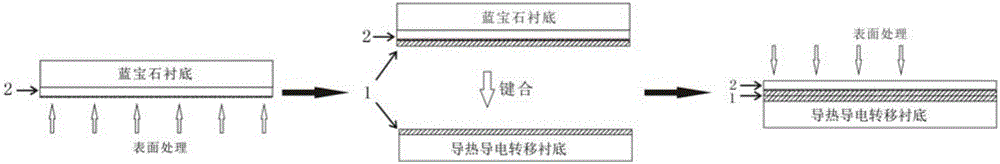

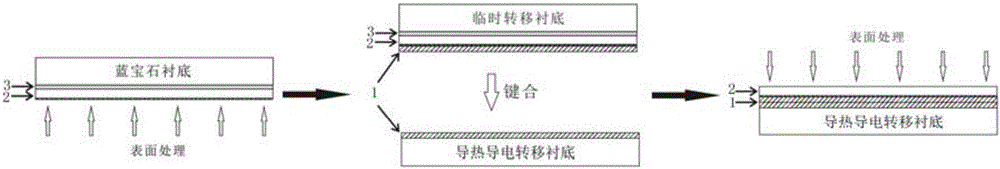

[0036] as attached figure 1 and 3 As shown in the figure, a preparation method of a GaN-based composite substrate is used to prepare a GaN-based composite substrate with a nitrogen polar surface facing upward. The GaN-based composite substrate sequentially includes a thermally conductive and conductive transfer substrate, a The dielectric layer 1 and the GaN-based epitaxial thin film 2, the method includes the following steps:

[0037] S11, epitaxially growing a GaN-based epitaxial thin film 2 on a sapphire substrate to obtain a sapphire-GaN-based composite substrate.

[0038] S13, prepare the bonding medium layer 1 on the surface of the GaN-based epitaxial film 2 and the thermally conductive and conductive transfer substrate respectively, and then connect the b...

Embodiment 1

[0054] as attached Figure 4 As shown in the figure, a preparation method of a GaN-based composite substrate is performed on the surface of the GaN-based epitaxial film before transfer, and the surface treatment is performed by dry etching using HVPE equipment. The transfer substrate is a Si substrate, which is used to prepare a GaN-based composite substrate with nitrogen polarity facing upward. The preparation method includes the following steps:

[0055] S11, epitaxially growing a GaN-based epitaxial thin film 2 on a sapphire substrate to obtain a sapphire-GaN-based composite substrate. Specifically, on a 2-inch 430-micron-thick flat sapphire substrate, a 4.5-micron-thick GaN-based epitaxial film was firstly grown epitaxially by MOCVD technology, and then the GaN-based epitaxial film was grown and thickened to 35 microns by growing in HVPE.

[0056] S12, dry etching the surface 2 of the GaN-based epitaxial thin film of the obtained sapphire GaN-based composite substrate in ...

Embodiment 2

[0060] A preparation method of a GaN-based composite substrate, the surface of the GaN-based epitaxial thin film is subjected to surface treatment before and after the transfer, the surface treatment is performed by dry etching using HVPE equipment and ICP equipment, and the bonding medium layer 1 material is made of Ni / Pt alloy, AlSi substrate is used as thermal conductive and conductive transfer substrate, and is used to prepare a GaN-based composite substrate with nitrogen polarity facing upward. The preparation method includes the following steps:

[0061] S11, epitaxially growing a GaN-based epitaxial thin film 2 on a sapphire substrate. Specifically, on a flat sapphire substrate with a thickness of 2 inches and a thickness of 430 microns, a GaN-based epitaxial film with a thickness of 4.5 microns was grown epitaxially by MOCVD technology, and then the GaN-based epitaxial film was grown and thickened to 30 microns in HVPE.

[0062] S12, etching the surface of the GaN-base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap