Tubular bus O-shaped wiring terminal

A technology of terminals and tubular bus bars, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of inability to meet the cross-sectional area of effective carrier fluid, lack of effective cross-sectional area, installation environment restrictions, etc. The effect of current delivery, reduced installation costs, and reduced electric field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

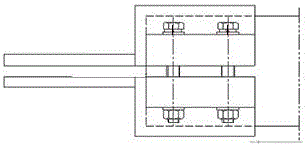

[0022] An O-shaped terminal for a tubular busbar, comprising a locking mechanism, a tubular busbar, and an O-shaped terminal, wherein the O-shaped terminal is made of T2 copper, and the O-shaped terminal includes a first terminal and a second terminal , the first terminal is provided with a first arc hole, the second terminal is provided with a second arc hole, the first arc hole and the second arc hole cooperate to form an O-shaped hole, the The tubular busbar is placed in the O-shaped hole;

[0023] The tops of the first terminal and the second terminal are both arc-shaped, and cooperate with each other to form a semicircle, the side wall of the first terminal is provided with a first groove, and the side wall of the second terminal is provided with a second groove , the first groove and the second groove are arranged symmetrically, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com