Line protection sleeve

A technology for protecting casings and casings, applied in electrical components and other directions, can solve the problems of unsatisfactory use effect and single function of protection pipes, and achieve the effects of low cost, low maintenance cost and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the invention will be further described in detail below.

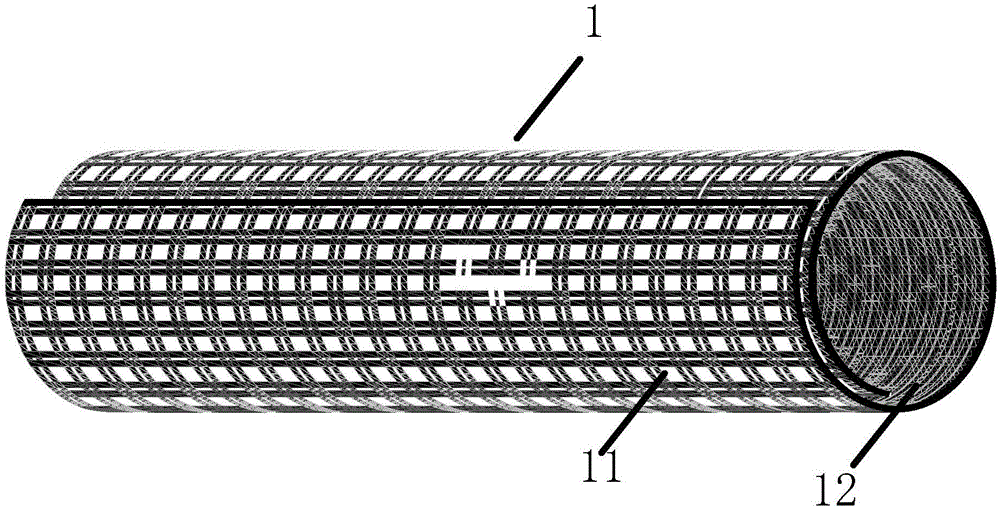

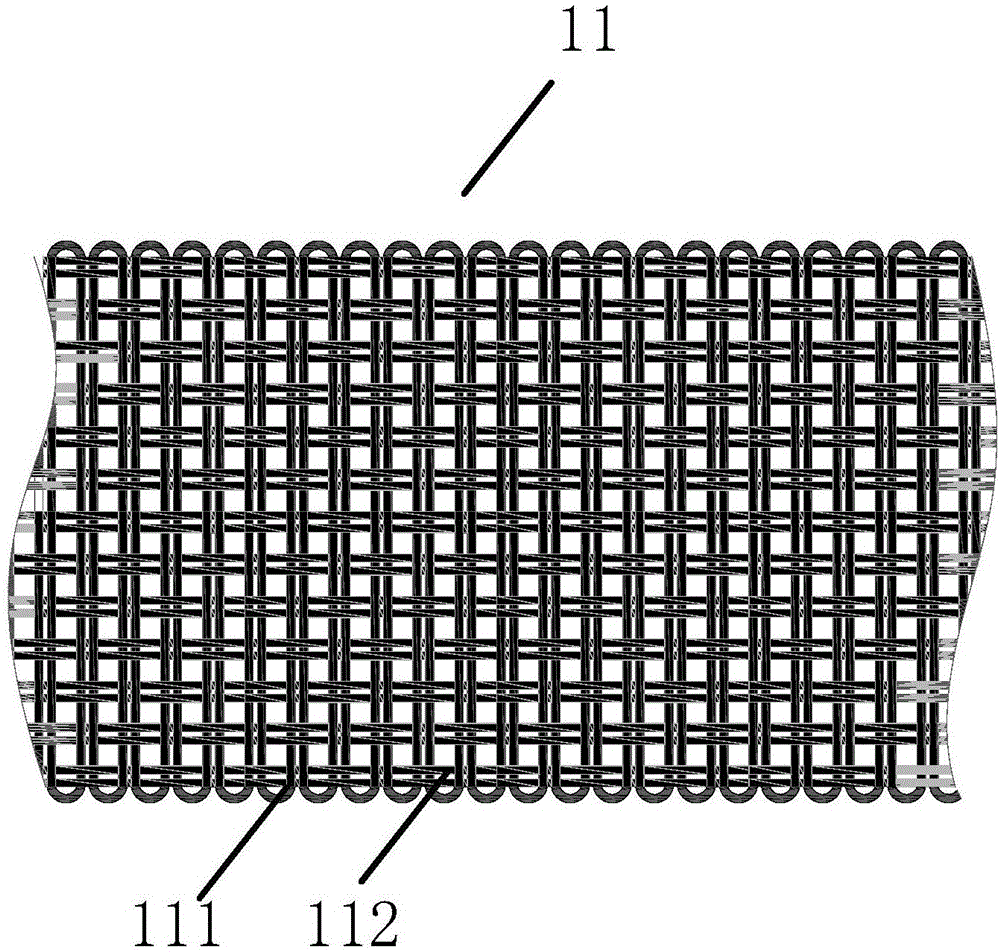

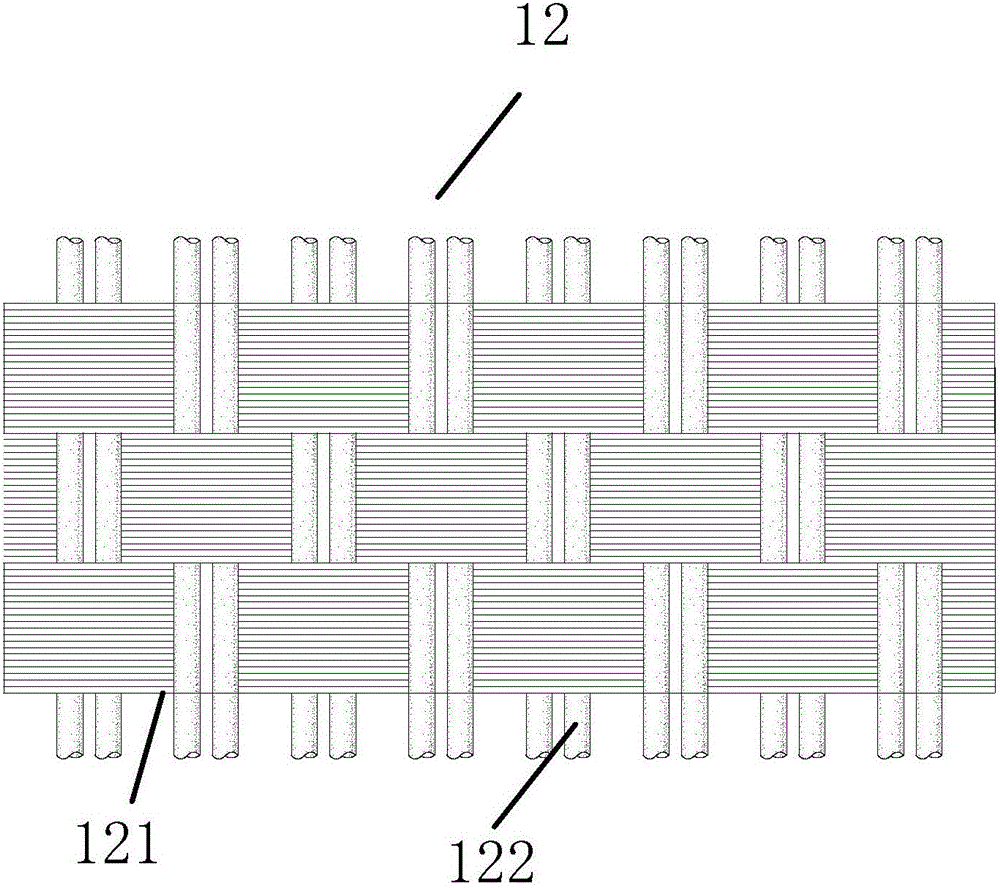

[0031] Such as Figure 1-4 As shown, a wire protection sleeve of an embodiment includes a sleeve main body 1 and a sleeve cavity, the sleeve cavity has a front opening, a rear opening and a side opening, and the sleeve main body 1 includes an outer layer 11 and an inner layer Layer 12, the peripheral edges of the outer layer 11 and the corresponding peripheral edges of the inner layer 12 are connected by plastic wires, the sleeve main body 1 is bent to form the sleeve cavity, and the sleeve main body 1 includes: for forming The first part of the side wall of the casing cavity and the second part used to block the side opening of the casing cavity, the outer layer 11 is braided by plastic monofilament, and the inner layer 12 is made of plastic monofilament The diameter of a single plastic monofilament is larger than that of a single plastic multifilament. Therefore, in the case of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com