Marine vessel with a large propeller and gearbox

A propeller, gearbox technology, applied in the field of ships with large propellers and gearboxes, which can solve the problems of design not proved to be competitive, increased resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

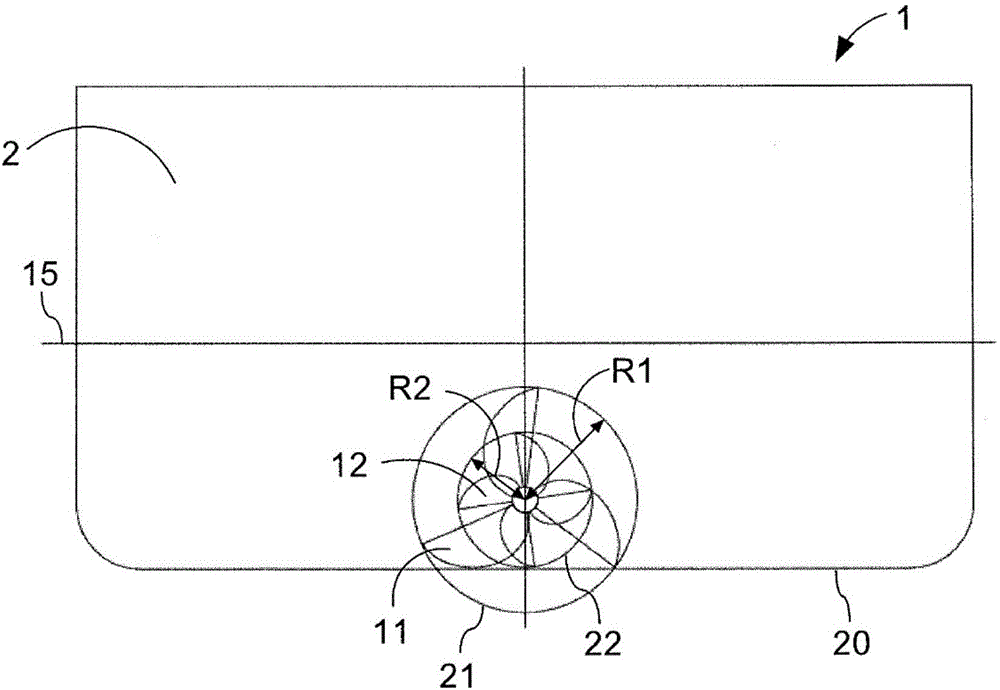

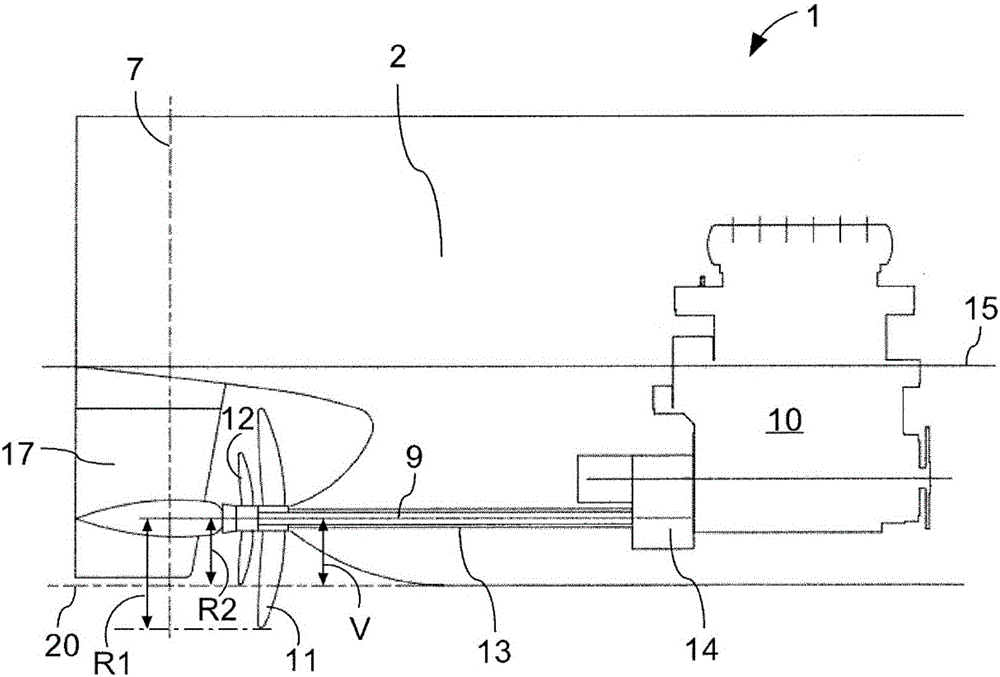

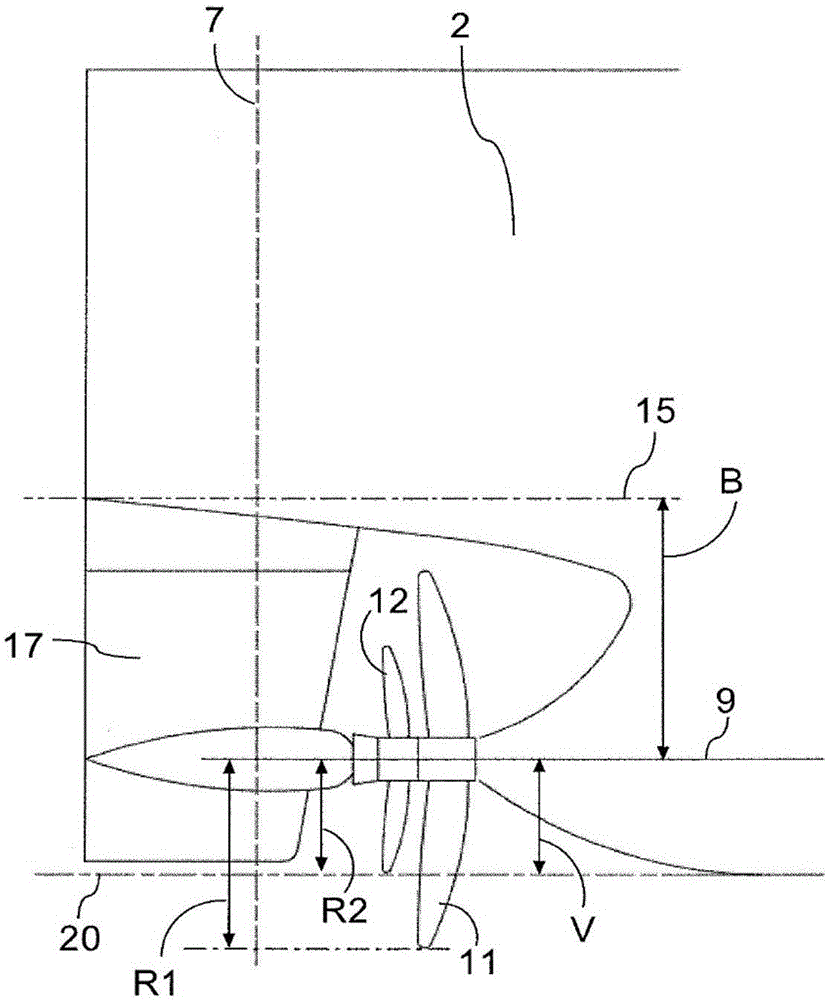

[0029] In the following detailed description, a vessel will be described by way of exemplary embodiments. figure 1 , figure 2 and image 3 The stern of the ship is schematically shown. Ship 1 includes hull 2 and superstructure 3 (such as Figure 10 shown). In one embodiment, the ship 1 is a cargo ship. The vessel 1 is designed with a predetermined draft selected such that the draft of the vessel 1 does not exceed the water depth of the port of call. This draft is determined as the depth of the base line 20 of the hull 2 when the vessel 1 is fully laden. The baseline extends roughly between the bow and the stern of the hull 2 . Also shown is the waterline 15 of the vessel 1 in a ballasted state.

[0030] Internal combustion engine 10 is located inside hull 2 . In one embodiment, the internal combustion engine 10 is a large, low-speed operating two-stroke auto-ignition internal combustion engine. The large two-stroke internal combustion engine 10 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com