Arc extinguish chamber assembling tool

A technology for assembling tooling and arc-extinguishing chambers, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of high labor intensity and low assembly efficiency, and achieve the effects of low labor intensity, high assembly efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

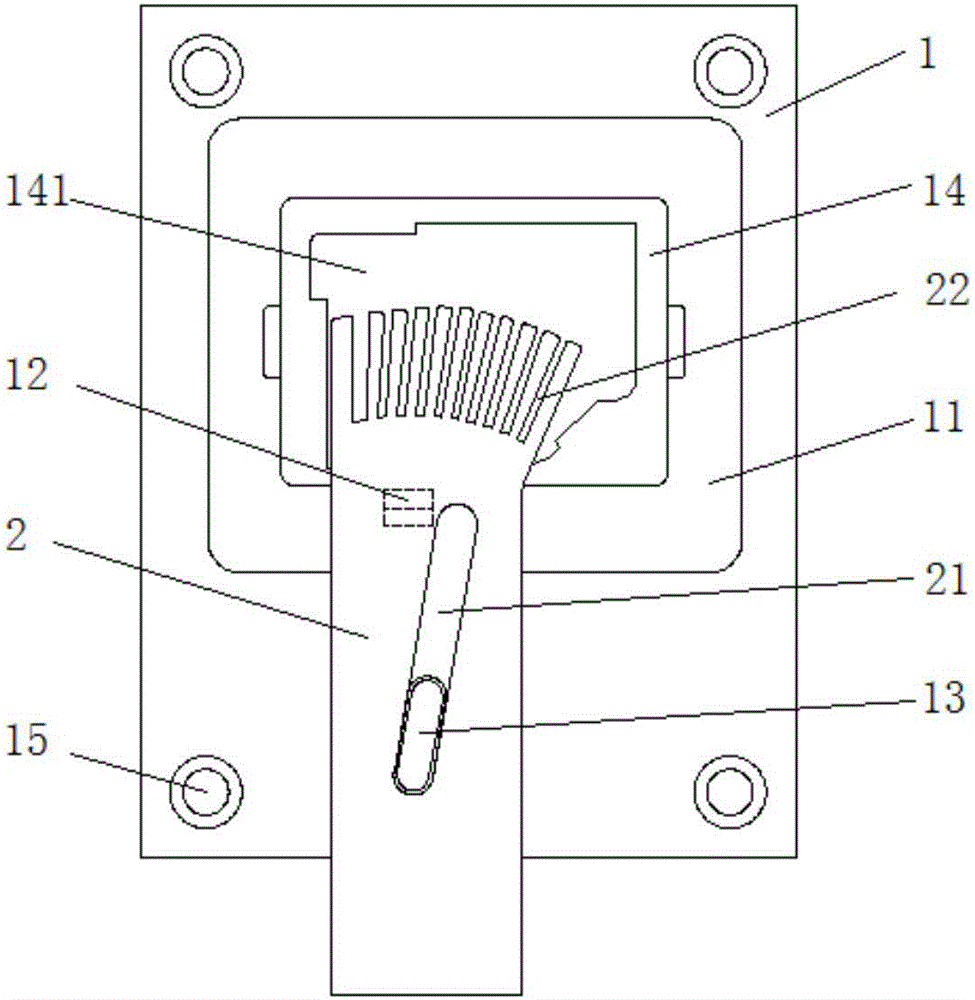

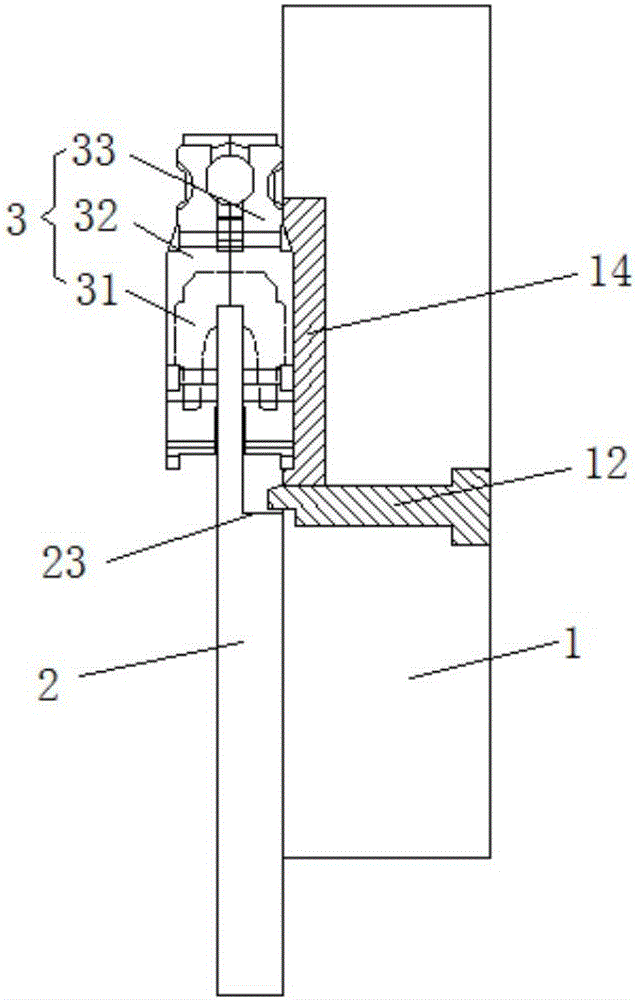

[0024] Embodiment one: if figure 1 and figure 2 As shown, a tool for assembling an arc extinguishing chamber includes a bottom plate 1 and an arc extinguishing blade positioning plate 2 . The arc extinguisher positioning plate 2 is a plate-like structure placed horizontally. There is a long strip-shaped and inclined guide hole 21 in the middle of the arc extinguisher positioning plate 2. There are several card slots 22 at the front end of the arc extinguisher positioning plate 2. The front end Limiting steps 23 are provided below. The width of each slot 22 and the arrangement of the slots 22 correspond to the arc extinguishing plates 31 in the arc extinguishing chamber 3 one by one. The center of the bottom plate 1 is provided with an arc extinguishing chamber assembly area 11 , and four corners are provided with fixing holes 15 . The arc extinguishing chamber assembly area 11 is provided with a positioning mechanism for limiting the movement of the left arc extinguishing ...

Embodiment 2

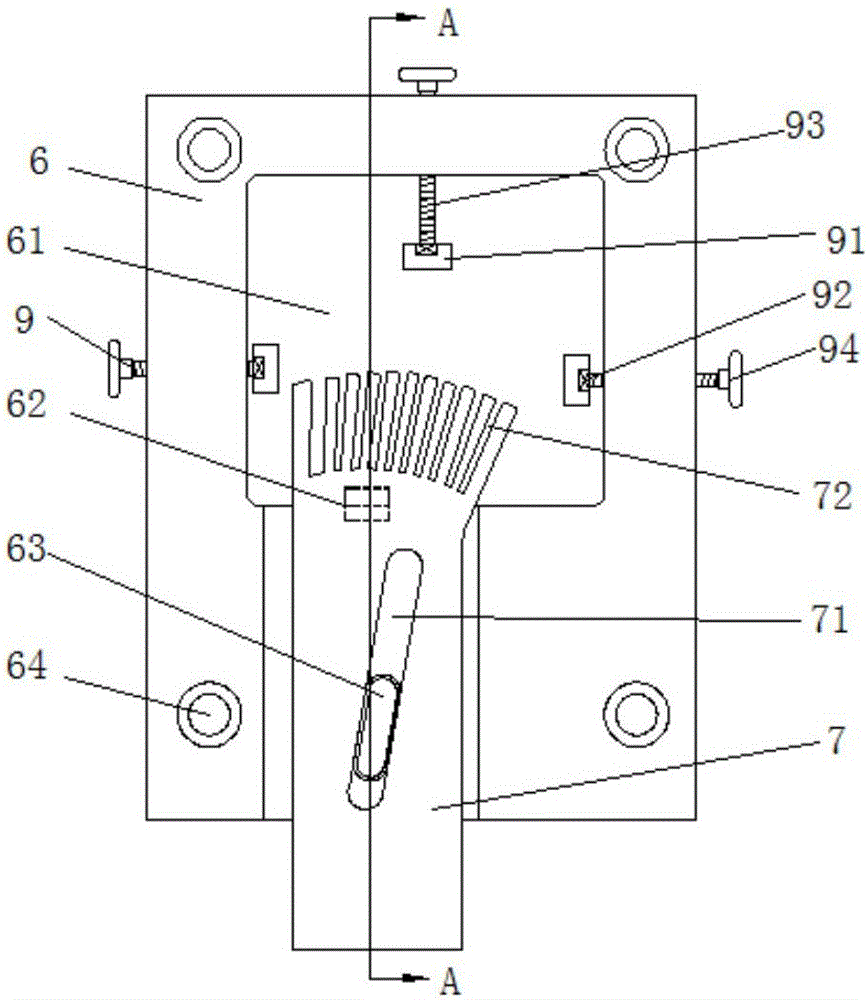

[0025] Embodiment two: if Figure 3-5 As shown, a tool for assembling an arc extinguishing chamber includes a bottom plate 6 and an arc extinguishing blade positioning plate 7 . The arc extinguishing plate positioning plate 7 is a plate-shaped structure placed horizontally, and the arc extinguishing plate positioning plate 7 is provided with a long strip-shaped and inclined guide hole 71 in the middle. A limit step 73 is provided below. The width of each locking slot 72 and the arrangement of the locking slots 72 correspond to the arc extinguishing plates in the arc extinguishing chamber one by one. The center of the bottom plate 6 is provided with an arc extinguishing chamber assembly area 61 , and four corners of the bottom plate are provided with fixing holes 64 . The arc extinguishing chamber assembly area 61 is a rectangular cavity capable of accommodating the left or right arc extinguishing hood 8. The left and right ends and the front end of the arc extinguishing cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com