Special monocoque coach tire assembly equipment

A tire assembly and full-carrying technology, which is applied in tire installation, tire parts, vehicle parts, etc., can solve the problem of high labor intensity in moving tires to holes, and achieve high promotional value, improved installation efficiency, and efficient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

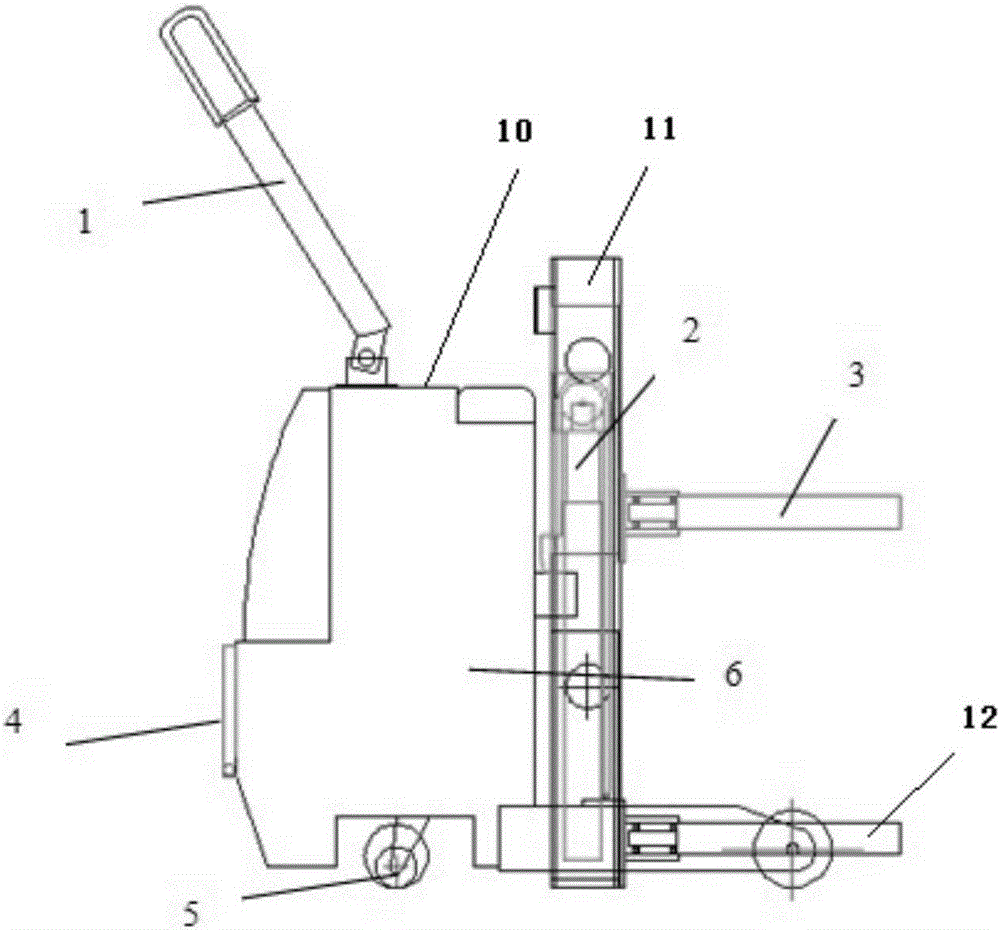

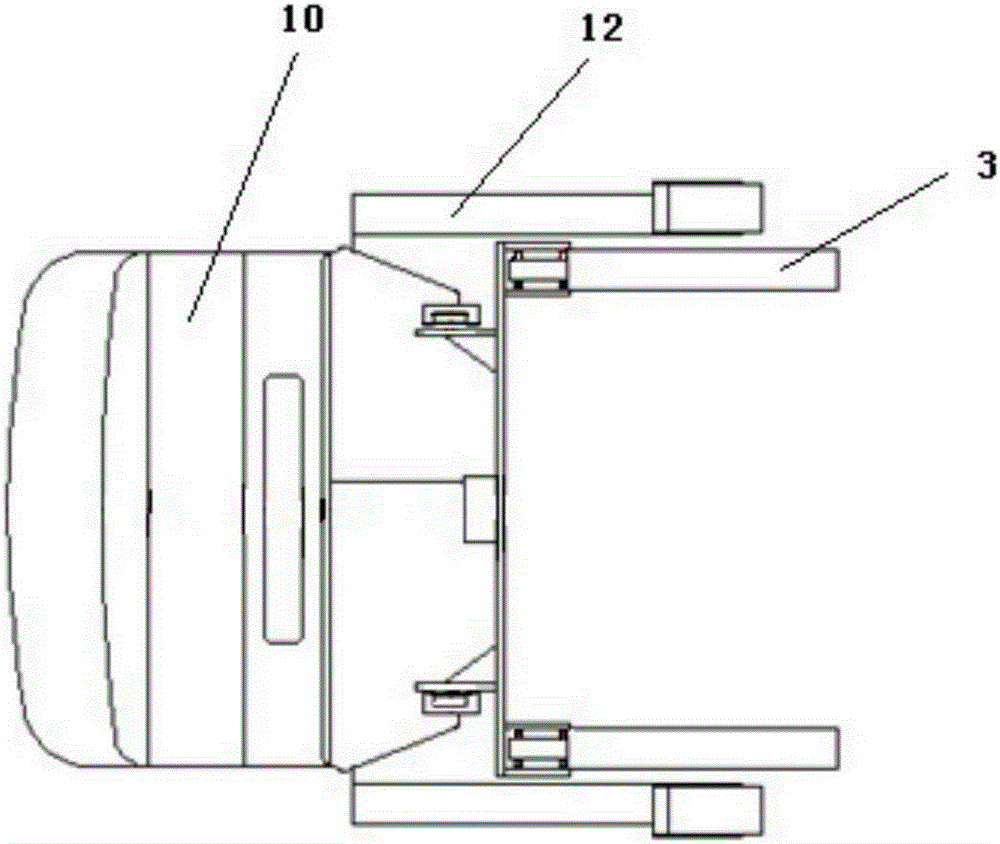

[0021] like figure 1 and figure 2 As shown, they are respectively the front view and the top view of the full-load passenger car tire assembly special tooling according to the present invention. The present invention provides a full load-bearing passenger car tire assembly special tooling with the functions of up and down lifting and front and rear travel, which mainly includes: a body 10, a control rod 1, a lifting cylinder 2, an auxiliary support 3, a foot pedal 4, a running mechanism 5 and Control system assembly6.

[0022] First of all, the full load-bearing passenger car tire assembly special tooling provided by the present invention has the function of lifting up and down, specifically:

[0023] The rear end of the body 10 is provided with a support 11 extending in the vertical direction, and the support 11 is provided with a lifting cylinder 2, and the piston rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com