A kind of preparation method of polyester fiber with catalytic degradation function

A polyester fiber, catalytic degradation technology, applied in chemical instruments and methods, separation methods, fiber treatment and other directions, can solve the problem of low durability of catalyst catalytic performance, and achieve stable and durable catalytic degradation performance, high catalytic activity, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of polyester fiber with purification function includes the following two parts:

[0034] 1)TiO 2 Preparation of intercalated graphene oxide particles:

[0035] Take 10g 800 mesh expanded graphite and 250g 98% sulfuric acid (H 2 SO 4 ), placed in a 5000mL container. In an ice-water bath, under the condition of 800 revolutions per minute, mechanically stir, make it fully mixed, and then slowly add 20 g of potassium permanganate to complete the reaction. The solution was moved to an oil bath at 40°C and operated at 600 rpm for 60 minutes. Add 300mL deionized water, react at 95℃ for 25min; continue to add 600mL deionized water, stir evenly, add 30g 30% hydrogen peroxide (H 2 O 2 ) Aqueous solution, the solution gradually changes from brown-black to bright yellow. Add deionized water, centrifuge and disperse at 5000 rpm, and wash to neutrality to obtain graphene oxide. Take the above-prepared graphene oxide in a hydrothermal reactor, seal it under 140℃ a...

Embodiment 2

[0040] The preparation method of polyester fiber with purification function includes the following two parts:

[0041] 1)TiO 2 Preparation of intercalated graphene oxide particles:

[0042] Take 8g 2000 mesh expanded graphite and 95g 98% sulfuric acid (H 2 SO 4 ), placed in a 5000mL container. Under the condition of 1000 revolutions per minute in an ice-water bath, mechanically stir, make it fully mixed, and slowly add 15 g of potassium permanganate to complete the reaction. The solution was transferred to an oil bath at 60°C and operated for 100 minutes at 1000 revolutions per minute. Add 500mL deionized water, react at 100℃ for 30min; continue to add 800mL deionized water, stir evenly, add 25g 30% hydrogen peroxide (H 2 O 2 ) Aqueous solution, the solution gradually changes from brown-black to bright yellow. Add deionized water, centrifuge and disperse at 8000 rpm, and wash to neutrality to obtain graphene oxide. Take the above-prepared graphene oxide in a hydrothermal reactio...

Embodiment 3

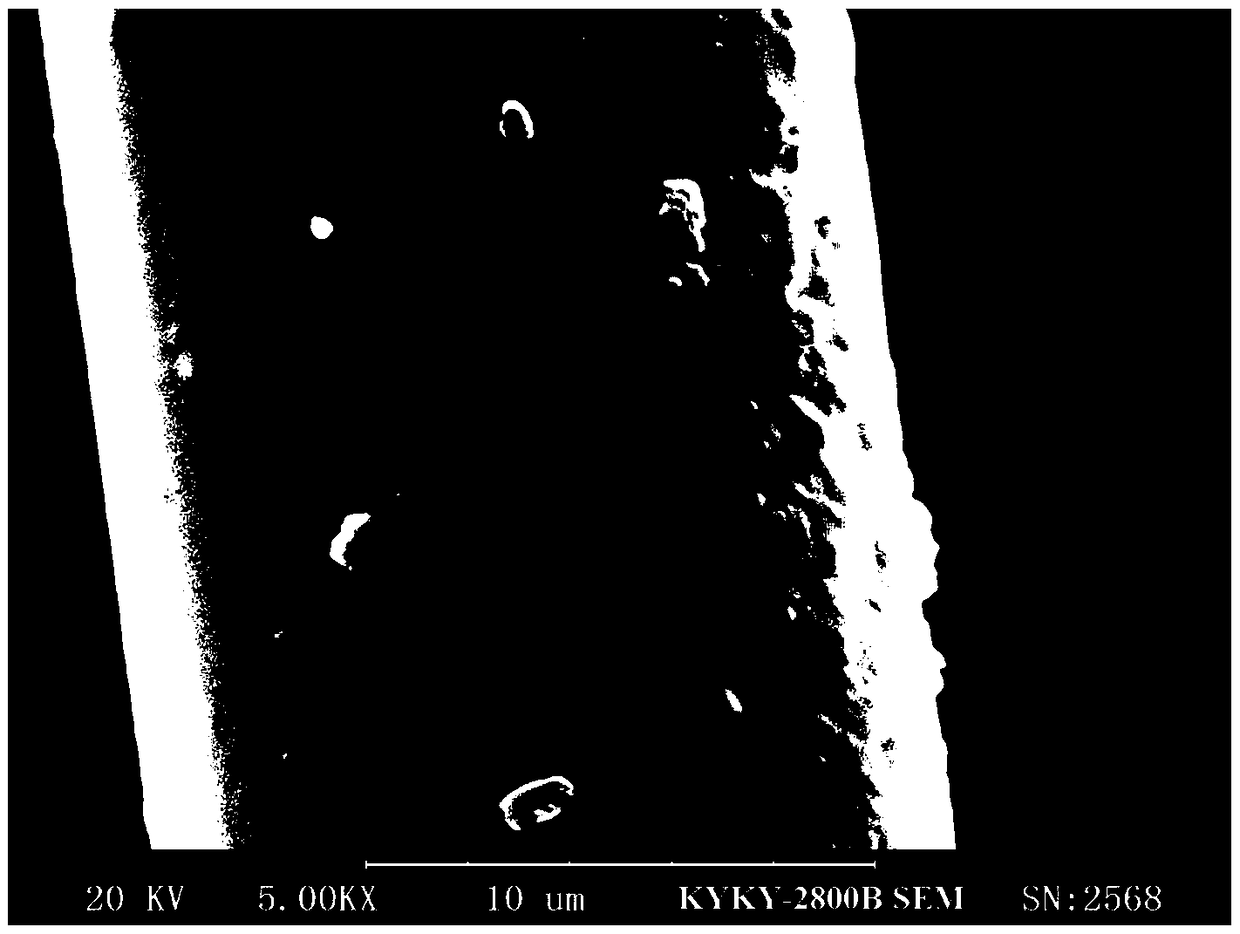

[0047] The graphene oxide and TiO obtained in Example 1-2 2 Intercalated graphene oxide particles, containing TiO 2 The polyester fibers intercalated with graphene oxide particles were identified, and the results are shown in the accompanying drawings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com