Integrally formed granular carbon adsorbent as well as preparation method and application thereof

A granular carbon and adsorbent technology, applied in the direction of adsorption purification/separation, chemical instruments and methods, gas fuel, etc., can solve the problems of specific surface area, adsorption performance and mechanical strength reduction of adsorbent materials, and achieve excellent working ability, high Economic value, effect of increasing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

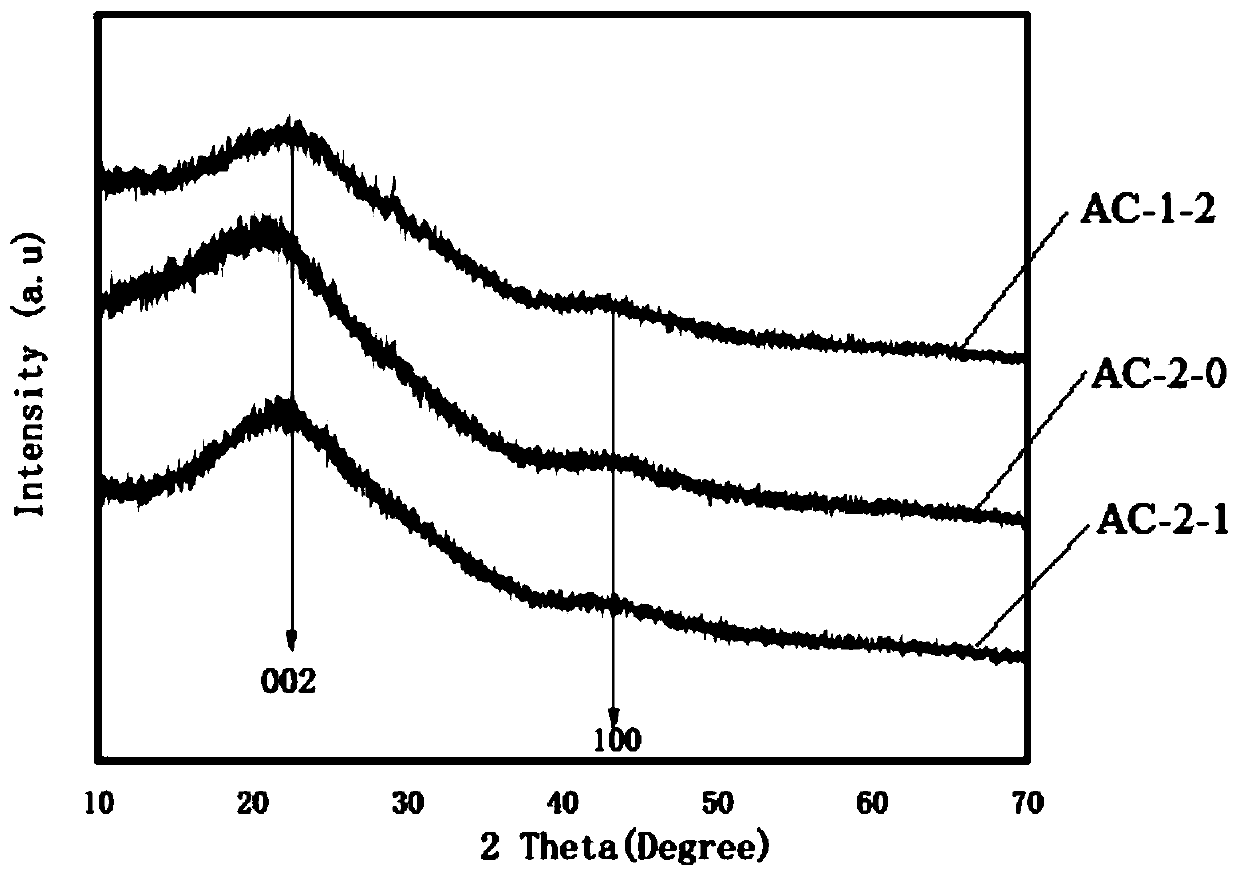

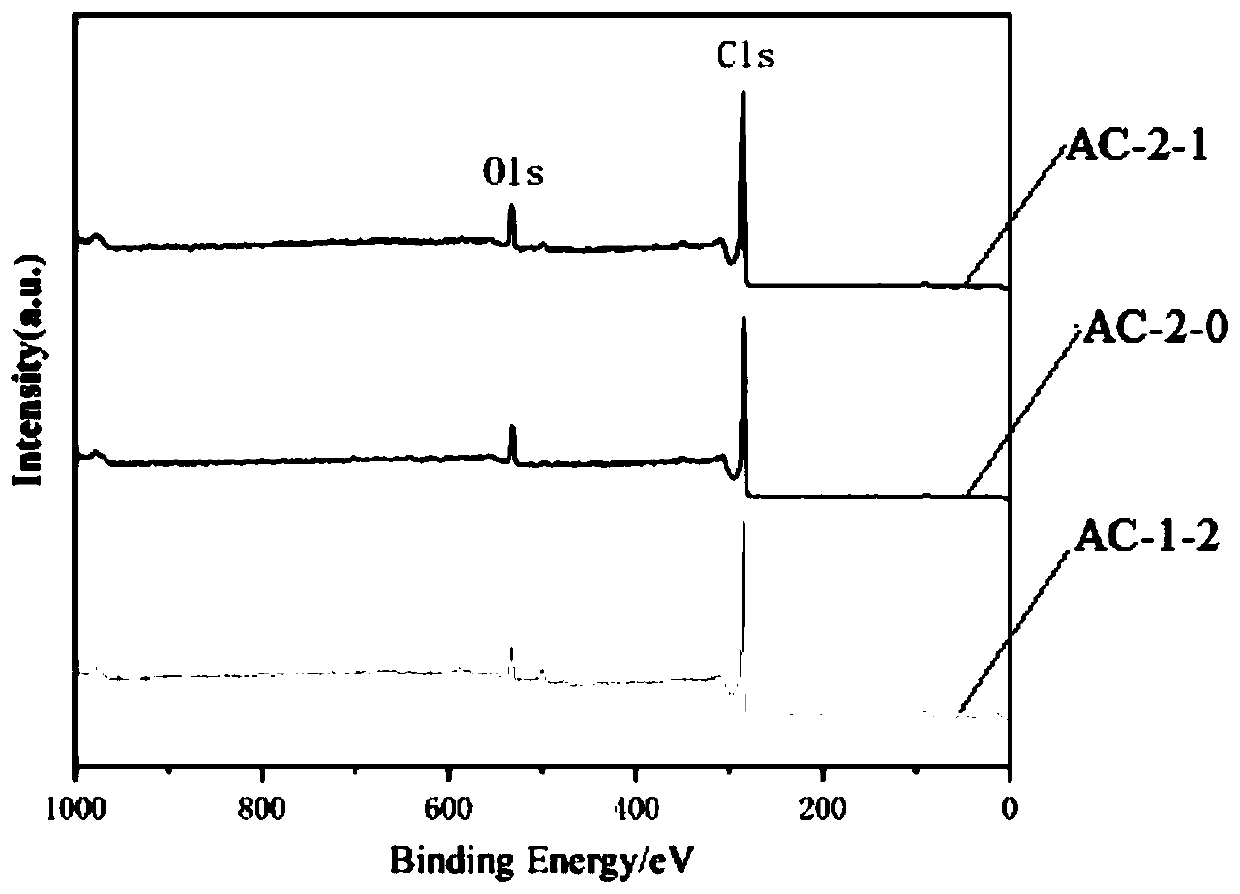

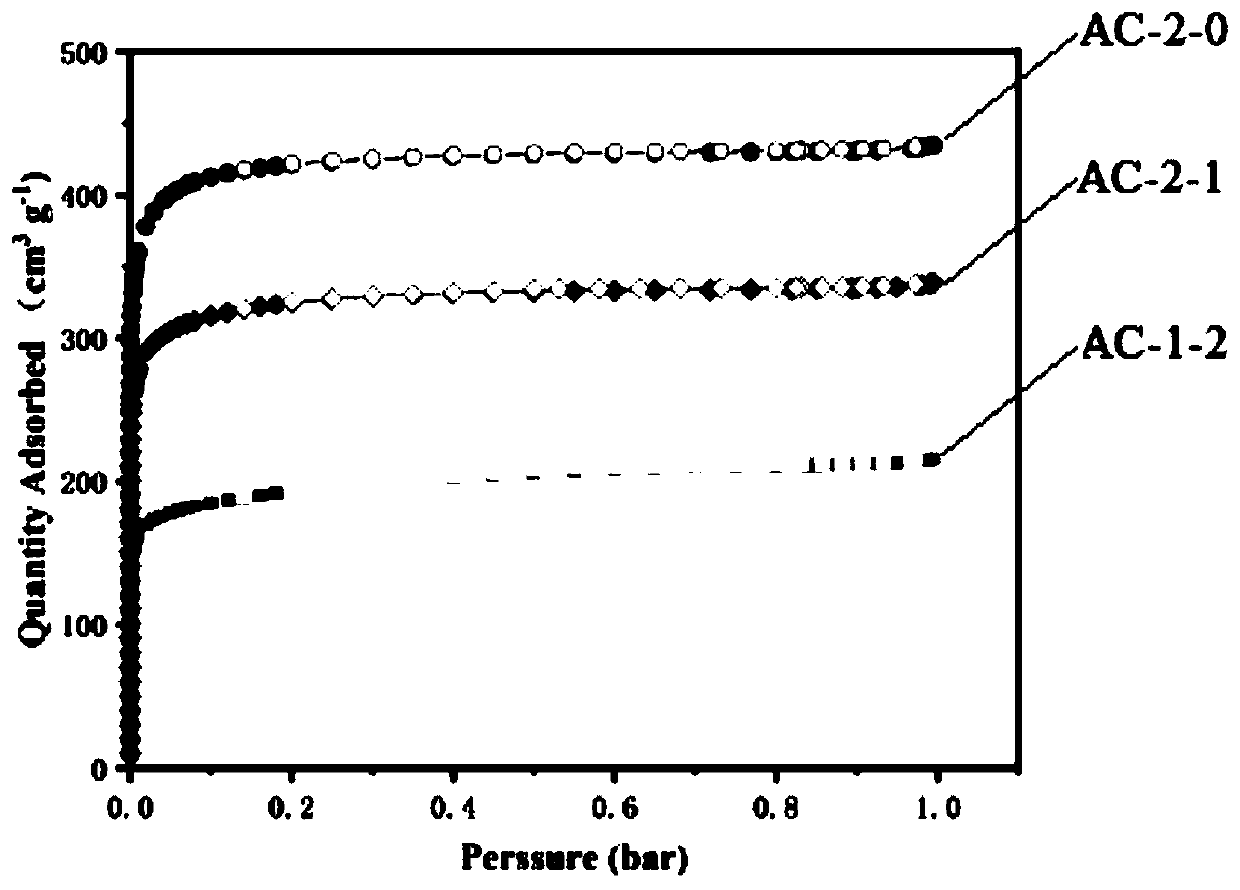

Embodiment 1

[0038] A method for preparing an integrated granular carbon adsorbent includes the following steps:

[0039] (1) Preparation of pre-carbonized materials:

[0040] In a nitrogen atmosphere, put the camellia shell into the quartz ark and then transfer it into the tube furnace, continue to heat up to 550°C at a rate of 10°C / min and keep it for 1 hour to obtain the pre-carbonized material;

[0041] (2) Mixing of porogen and pre-carbonized material:

[0042] The pre-carbonized material prepared in step (1) is crushed to a particle size of 300 mesh, and then the pre-carbonized material, KOH and ZnCl 2 Add to deionized water and make KOH and ZnCl 2 Dissolve completely, stir for 8 hours, and then dry at 85°C for 6 hours to prepare a mixture;

[0043] Among them, KOH and ZnCl 2 The ratio of mass to carbonized material is 1:2:1;

[0044] (3) Preparation of granular carbon adsorbent:

[0045] In a nitrogen atmosphere, the mixture prepared in step (2) is heated to 750°C at a rate of 10°C / min in a tub...

Embodiment 2

[0047] The operation steps are the same as in Example 1, except that the KOH and ZnCl 2 The ratio of mass to carbonized material was replaced from 1:2:1 to 2:0:1 to prepare a granular carbon adsorbent (AC-2-0).

Embodiment 3

[0049] The operation steps are the same as in Example 1, except that the KOH and ZnCl 2 The mass ratio of carbonized material to carbonized material was changed from 1:2:1 to 2:1:1 to prepare particulate carbon adsorbent (AC-2-1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com