Husk and husked rice gravity separation device

A technology of paddy separation and dispersing device, which is applied in the direction of solid separation, dust removal, and filtration, etc., which can solve the problems affecting environmental sanitation and human health, security, and high labor intensity, so as to protect the environment and human health and achieve high efficiency. Feeding and separation, the effect of ensuring the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

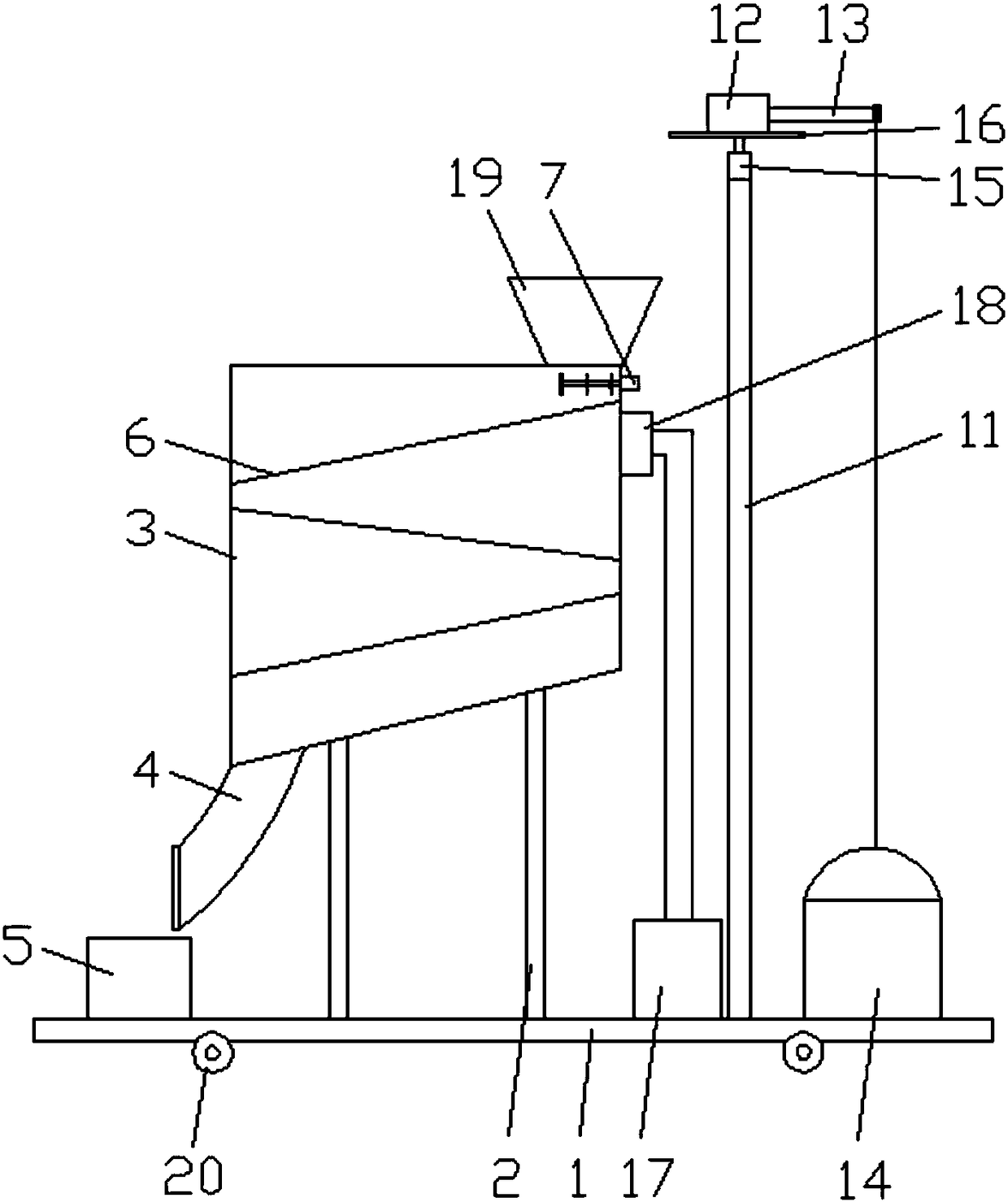

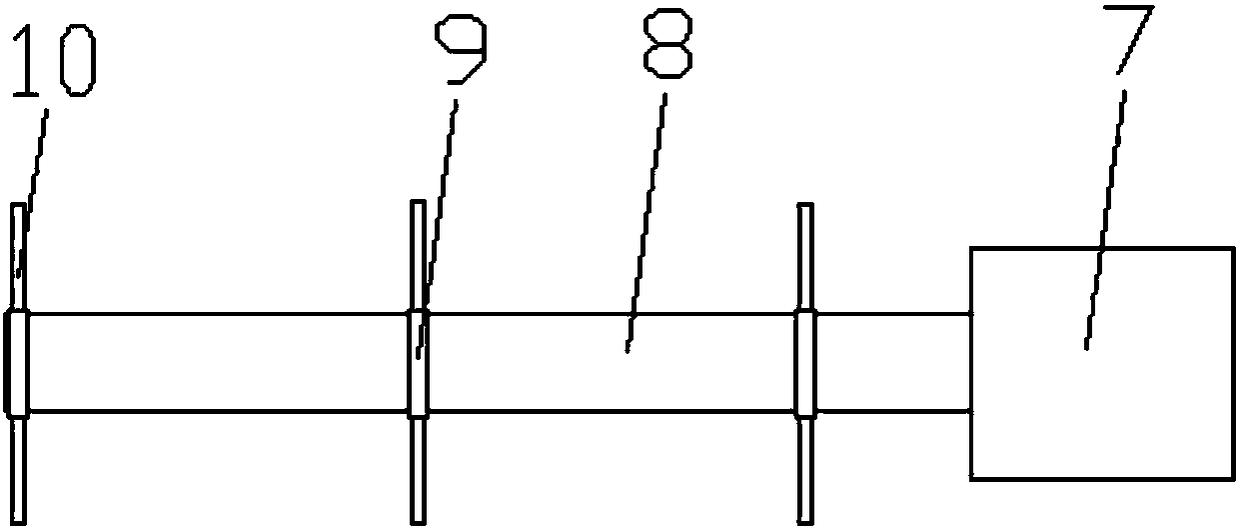

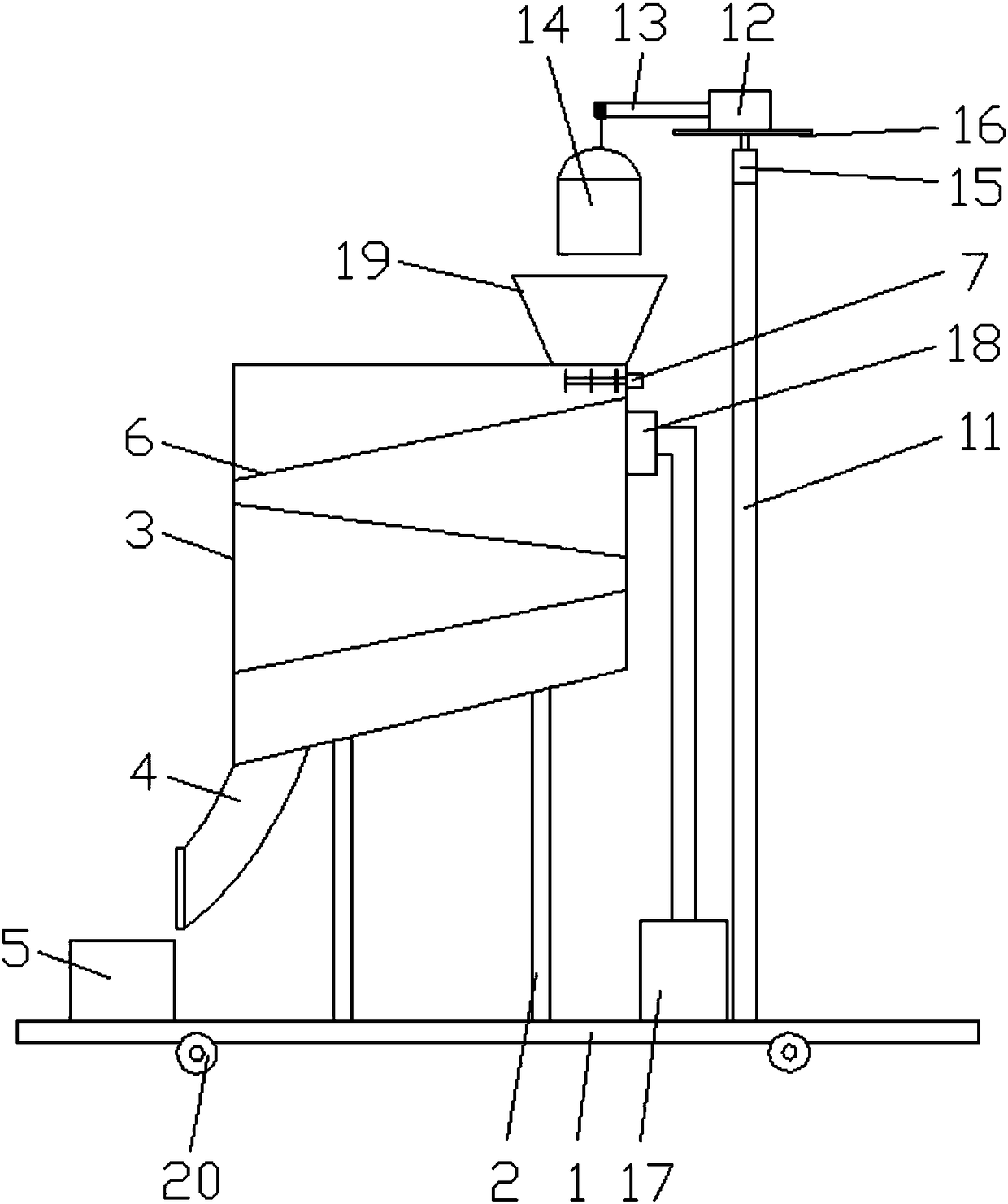

[0042] Such as figure 1 , figure 2 with image 3 As shown, in this embodiment, the feeding device includes a lifting column 11, and the top of the lifting column 11 is provided with a rotating mechanism. The rotating mechanism also includes a rotating motor 15 that is vertically arranged and installed on the top of the lifting column 11. The shaft is fixedly connected to the lower surface of the turntable 16, the turntable 16 is horizontally provided with a lifting motor 12, the lifting motor 12 is fixed on the upper surface of the turntable 16, the output shaft of the lifting motor 12 is connected to one end of the fixed rod 13, and the other end of the fixed rod 13 The set is equipped with a winding reel, which is connected to the feeding barrel 14 on the base 1 through a rope. The bottom of the feeding barrel 14 is provided with a discharge port, and a solenoid valve is provided at the discharge port, and the solenoid valve is electrically connected to the controller. , ...

Embodiment 2

[0046] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the feeding device adopts a "Z" shaped suction pipe 21, the discharge port of the suction pipe 21 is located above the feed hopper 19, and the top of the suction pipe 21 An aspirator is arranged at the place, and the aspirator sucks the paddy into the suction pipe 21 and sends it to the feed hopper 19. Other structures and operating principles are all the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com