Patents

Literature

30results about How to "No granulation required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing semi-aromatic nylon

The invention discloses a method for preparing semi-aromatic nylon and belongs to the technical field of macromolecular material synthesis. The method comprises the following steps: (1) uniformly mixing aliphatic diamine and water of which the weight is two to ten times that of the aliphatic diamine, heating the mixture to the temperature of between 50 and 90 DEG C, adding aromatic diacid into the mixture with stirring till a pH value of the solution reaches 7.0-7.7, continuously stirring for 1 to 5 hours, cooling the solution to room temperature, continuously stirring the solution for 1 to 5 hours again, and filtering and drying to obtain nylon salt for later use; and (2) adding the prepared nylon salt and a solvent to a polymerization kettle in a certain mixture ratio (0.5 to 3.0 g / mL), raising the temperature to between 190 and 230 DEG C under the protection of inert gas, keeping the pressure in the kettle between 2.0 and 3.0 MPa, discharging gas after 1 to 5 hours to make the pressure in the kettle reduced to normal pressure within 1 to 5 hours, raising the temperature to between 210 and 270 DEG C, and continuing to react for 1 to 5 hours, and discharging to obtain a powdery semi-aromatic nylon product. The method has mild reaction condition and low energy consumption; the product is easy to mold and machine; and the method solves the difficult problem of difficult discharging of the semi-aromatic nylon, and is applicable to industrialized production.

Owner:青岛智库生物技术有限公司

Pulverized coal ash and PVC (Poly Vinyl Chloride) composited micro-foaming building template reinforced by long glass fibers, and preparation method of building template

The invention relates to a pulverized coal ash and PVC (Poly Vinyl Chloride) composited micro-foaming building template reinforced by long glass fibers. The building template comprises a PVC composited modified material matrix, and the matrix consists of PVC, a heat stabilizer, a foaming agent, a foam stabilizer, a flexibilizer, an internal lubricant, an external lubricant, pulverized coal ash and high-strength long glass fibers. According to the pulverized coal ash and PVC (Poly Vinyl Chloride) composited micro-foaming building template reinforced by long glass fibers as well as a preparation method of the building template, the pulverized coal ash and the long glass fibers are adopted for filling and reinforcement, so that both the dimensional stability and the economical efficiency of the building template are enhanced greatly; the pulverized coal ash as a recyclable raw material is environment-friendly and energy-saving and can be used for replacing inorganic fillers such as calcium carbonate, so that the economic cost is lowered; in addition, the building template has advantages of light weight, resistance to medium acid-alkali corrosion, recyclability, heat insulation, good mechanical performance, flame retardation, wear resistance and the like; besides, the micro-foaming building template, which is manufactured by virtue of specific auxiliaries and an advanced micro-foaming technology, is environment-friendly, nontoxic, light in weight and resistant to medium acid-alkali corrosion; the service cycle of the building template is prolonged by 4-5 times than that of a wooden template and a bamboo-glue template, and the physical and mechanical properties of the building template are enhanced by 3-4 times; in addition, the building template can be demolded easily, and simultaneously the building template is recyclable, green and environment-friendly and saves the economic cost.

Owner:DAYING COUNTY SIPAIKE NEW MATERIALS

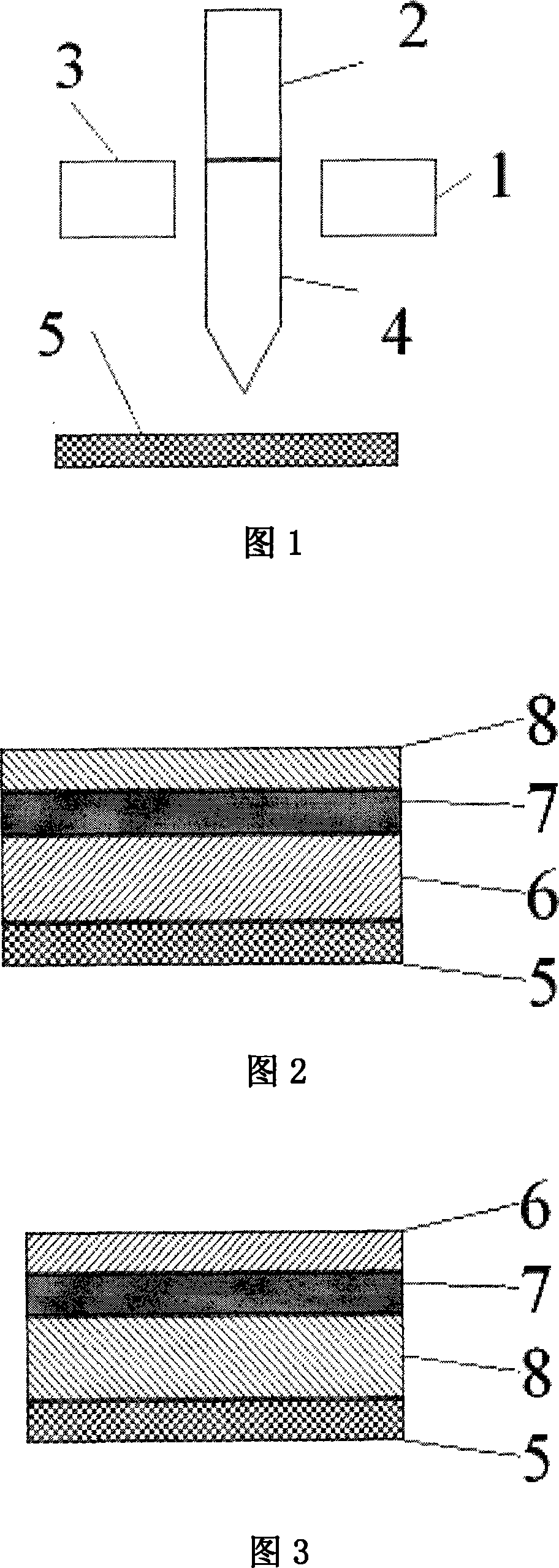

Method of producing three-in-one electrode of solid oxide fuel battery

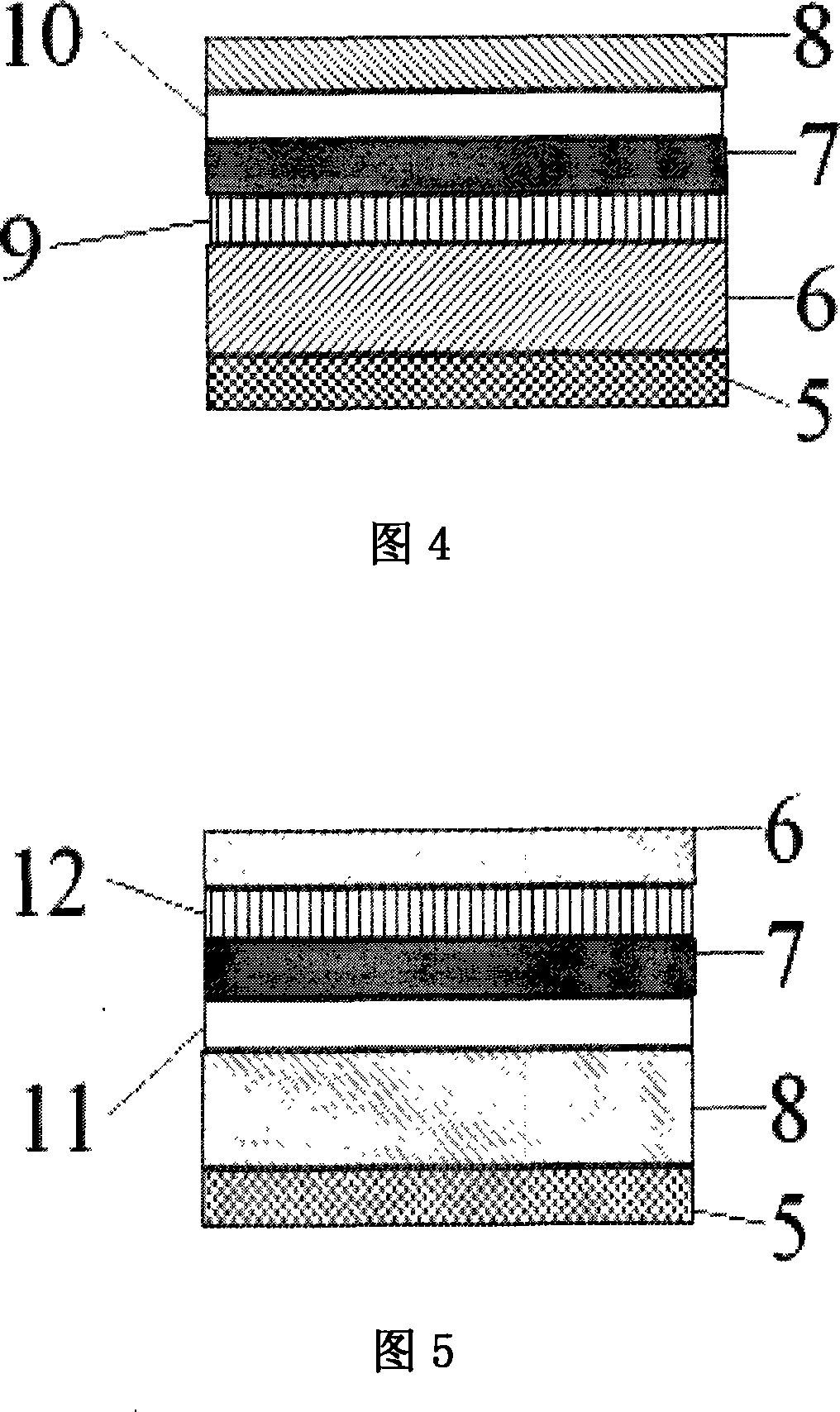

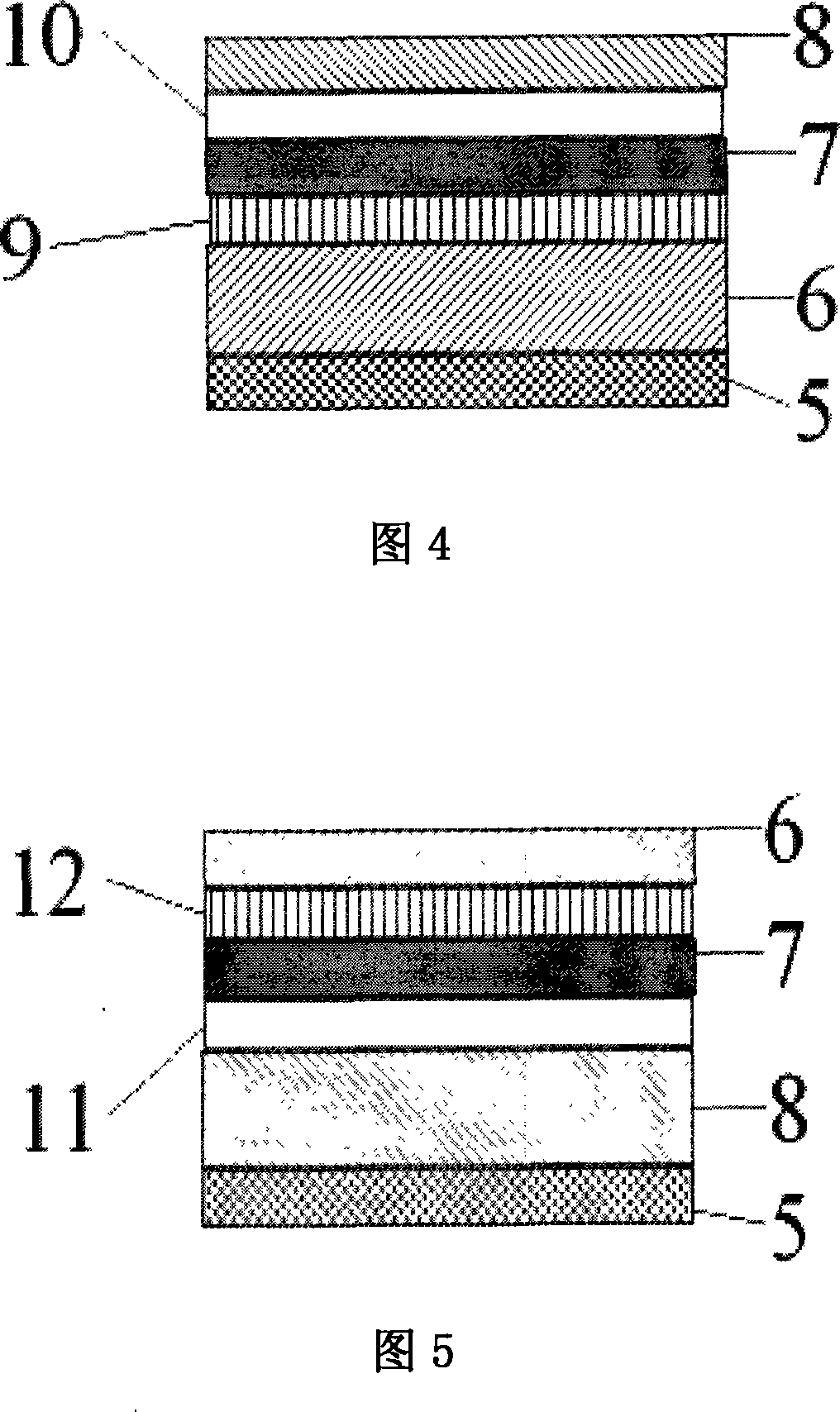

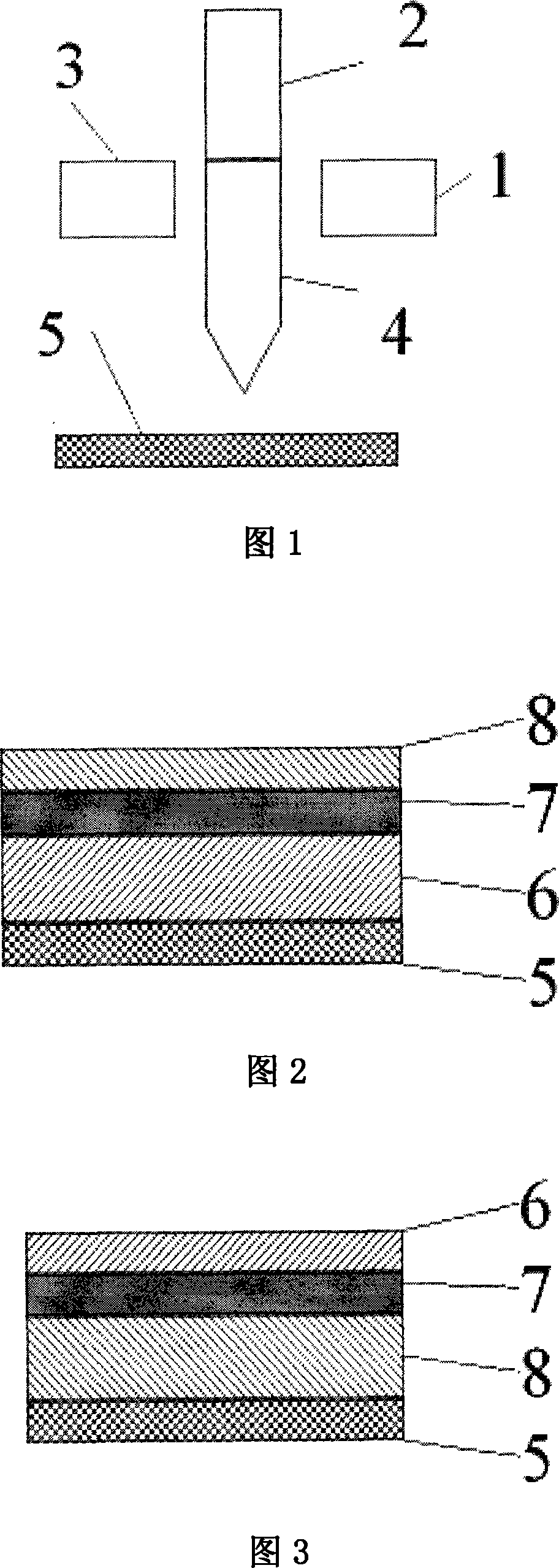

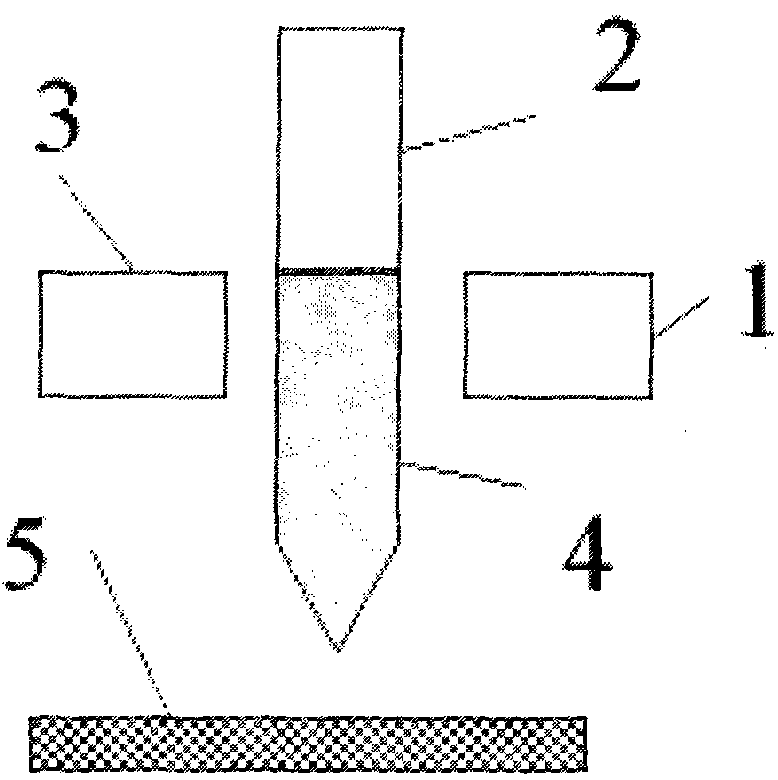

InactiveCN101183716AShort preparation cycleImprove operating performanceElectrolyte holding meansLiquid surface applicatorsBlock layerBlocking layer

The invention relates to a preparation method of membrane electrode assembly of solid oxide fuel cell, belonging to the plasma spraying method in the surface engineering area for the preparation of the core parts of the solid oxide fuel cell. The invention aims at preparing a compact electrolyte layer with smaller film thickness and evenly distributed material composition, effectively improving the electrolyte conductivity, reducing the internal resistance of SOFC, increasing the output power, and preparing porous and evenly distributed electrodes. The invention comprises following steps: preparation, spraying a support electrode, spraying an electrolyte layer, spraying cathode or anode. The invention has the advantages that fine nanometer or ultrafine powder can be directly used to spray without granulating; the material change between the function layers shows continuous gradually-changing gradient distribution, which can reduce the interface resistance and avoid the interface stratification; one time continuous forming is integrated with sintering process, and times of sintering are not needed, so that the invention is particularly suitable for spraying SOFC electrodes in the forms of flat plate, tuber, Mono-Block Layer Built and corrugating, large-area nanostructure coating, and short process making of nanometer devices.

Owner:HUAZHONG UNIV OF SCI & TECH

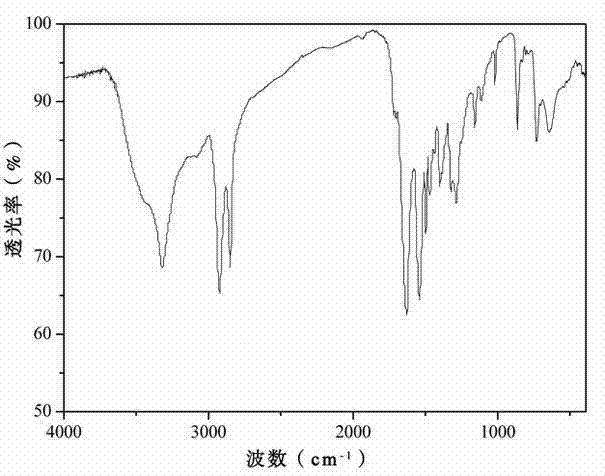

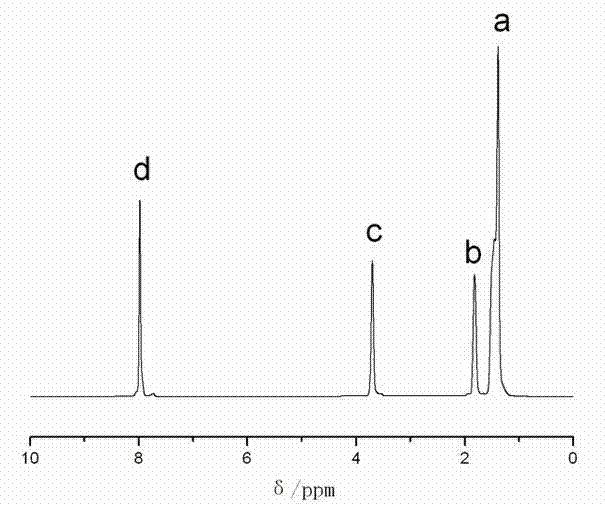

Long-carbon-chain semi-aromatic nylon PA14T and preparation method thereof

ActiveCN104327265AImprove toughnessEasy to processOrganic compound preparationAmino compound preparationPolymer scienceAutomotive industry

The invention relates to a long-carbon-chain semi-aromatic nylon PA14T and a preparation method thereof, belonging to the field of high polymer material synthetic technologies. The repeat unit is shown in the specification, and the degree of polymerization of the long-carbon-chain semi-aromatic nylon PA14T is n which is equal to 2 to 200. The preparation method comprises the following steps: (1) preparing nylon PA14T salt: adding 1,4-terephthalic acid and 1,14-tetradecanedioic diamine into water to perform salt forming reaction; (2) preparing semi-aromatic nylon PA14T: adding the nylon PA14T salt obtained in step (1) and a solvent into a polymerizer, heating up a reaction still to be at 200-240 DEG C under a condition of shielding gas, reacting for 1-4 hours under the pressure of 1.2 to 3 MPa, deflating until normal pressure is achieved and vacuumizing, and then carrying out polymerization reaction to obtain the semi-aromatic nylon PA14T. The PA14T is excellent in performance and is easy to process and form, and has the good market prospect, especially in electronic and electrical, automotive industries and the like; and besides, the long-carbon-chain semi-aromatic nylon PA14T is simple in technology, moderate in reaction condition, short in reaction time and low in energy consumption.

Owner:HENAN JUNHENG IND GRP BIOTECH CO LTD

Novel ignition powder and preparation method thereof

InactiveCN109896913ALow costReliable ignitionExplosive working-up apparatusAlkali metal salt explosive compositionsEngineeringCombustion

The invention discloses novel ignition powder and a preparation method thereof. The novel ignition powder comprises, by mass percentage, 3-9% of coating agent, 50-70% of main oxidant, 0-15% of auxiliary oxidant, 15-25% of fuel and 1-4% of combustion catalyst. The ignition powder prepared by the method has the advantages that the problems that existing ignition powder is narrow in application range, low in energy, poor in safety performance and complex in preparation process are solved; the prepared ignition powder is good in safety performance, high in energy, good in thermal stability and wide in combustion speed regulation range; meanwhile, the novel ignition powder is less prone to moisture absorption, safe and environmentally friendly, and the whole production, assembling and use process of the ignition powder is free of dust hazards.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

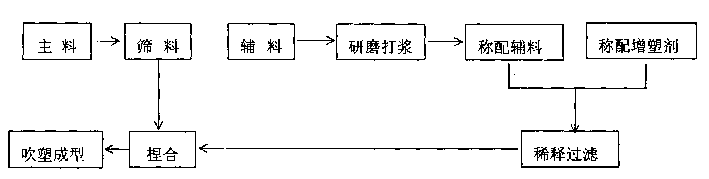

Polyvinyl alcohol hollow container preparation method

ActiveCN1962237ANo granulation requiredExtrusion-free granulationHollow articlesPolyvinyl alcoholEngineering

The invention relates to a method for producing polyvinyl alcohol hollow container, wherein it is characterized in that: it dissolves the modifier with compensated structure to the polyvinyl alcohol at 1-25deals into 20-50deals of deionized water, mixing, adding 50-80deals of polyvinyl alcohol, expanding at 20-60Deg. C, adding additives at 0-5deals, mixing, injection molding at injection device whose thermal treatment temperature is 60-170Deg. C and mould temperature is 10-150Deg. C, into hollow container; thermally processing at 40-250Deg. C or infrared drying for 3-120Deg. C, to improve the crystal degree, or at 20-80Deg. C, using crosslink solution whose density is 0.1-5% to treat it for 1-60min; thermally treating or infrared drying, to obtain the product with better insulated, physical and damp-proof properties.

Owner:SICHUAN UNIV

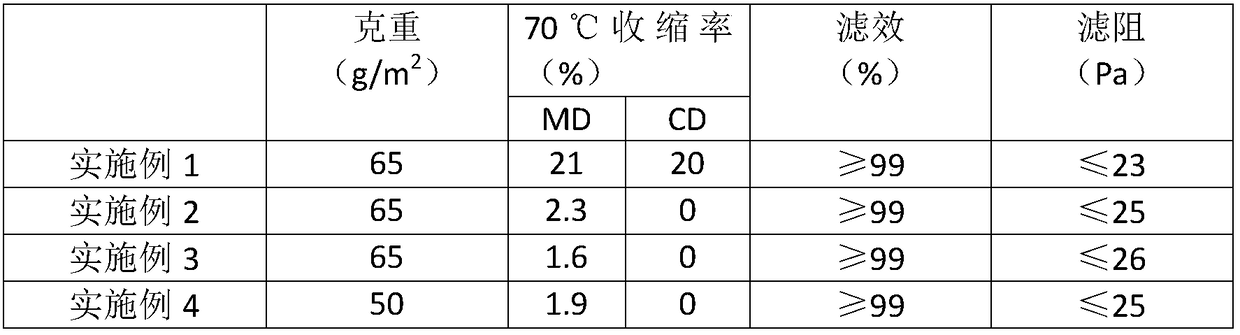

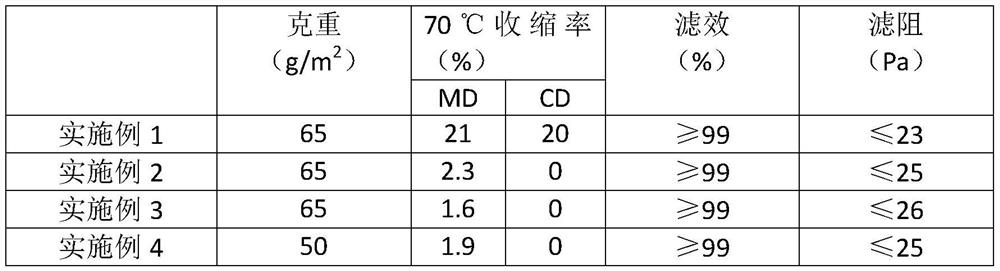

High-temperature-resistant polylactic acid melt-blow electret non-woven filter material and preparation method and application thereof

ActiveCN108708079ANo granulation requiredSimple production processHeating/cooling textile fabricsUltrasonic/sonic fibre treatmentHigh pressureHigh voltage

The invention provides a high-temperature-resistant polylactic acid melt-blow electret non-woven filter material and a preparation method and application thereof. The preparation method at least includes: a polylactic acid raw material without auxiliaries is subjected to a melt-blow process and high-voltage corona electret processing. The material prepared by the method does not need the adding offunctional auxiliaries and does not need granulation, and the production process is simplified.

Owner:上海精发实业有限公司

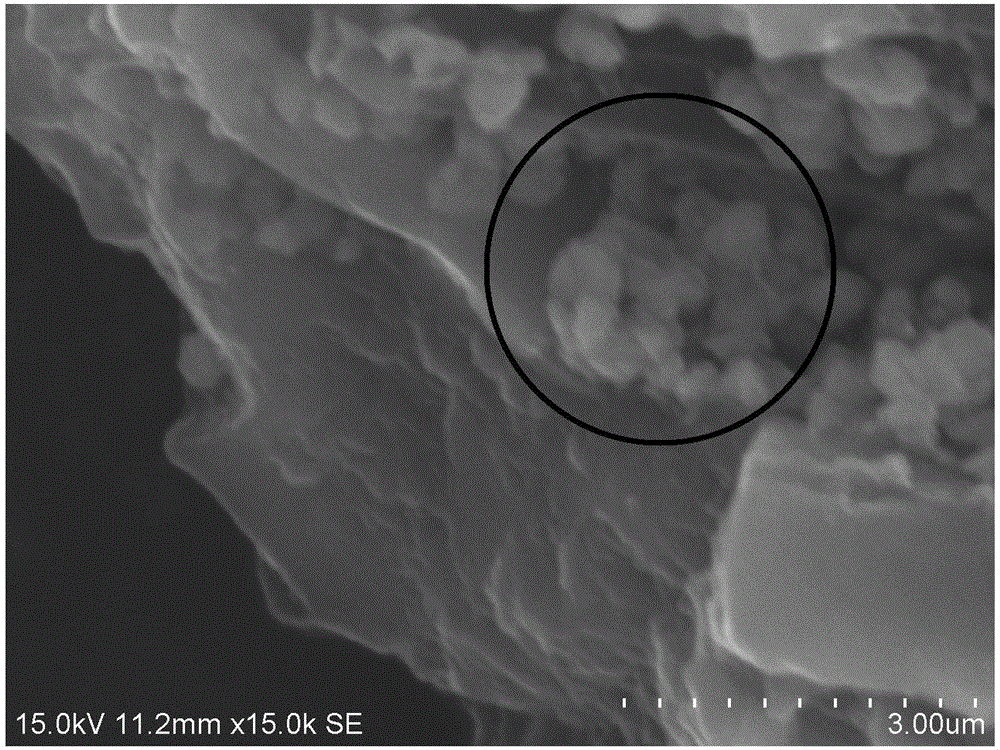

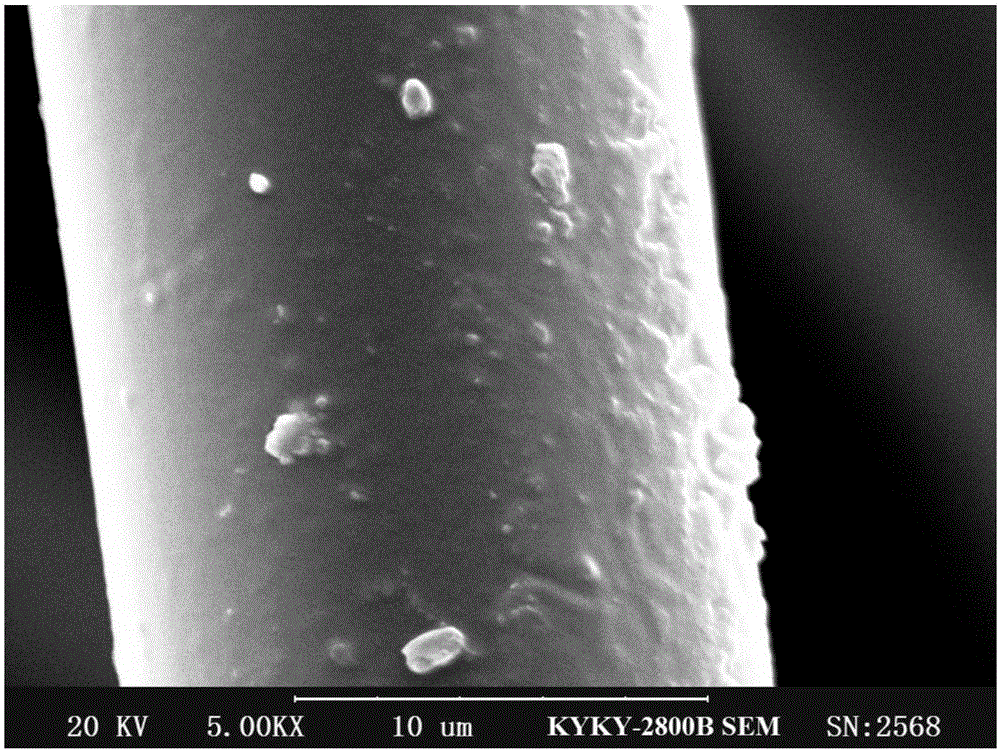

Polyester fibers with catalytic degradation function and preparation method thereof

ActiveCN106544858ANo granulation requiredSimple preparation processFibre typesDispersed particle separationFiberPolyester

The invention discloses polyester fibers with a catalytic degradation function and a preparation method thereof. The method comprises the following steps: firstly preparing TiO2 intercalated graphene oxide particles; cutting functional particles into micro-nano powder with a strong ultraviolet lamp; keeping the powder suspending in a cavity through air flow, and horizontally feeding colored polyester filaments into the cavity; softening the polyester fibers by controlling the temperature in the cavity so as to effectively bond with the powder; and carrying out hot pressing on the polyester filaments bonded with the functional powder to firmly bond the powder and the polyester fibers. The prepared novel polyester fibers have excellent catalytic degradation performance for aldehydes, benzene and other organic matters in vehicles; and the method is simple and feasible, and the catalytic degradation performance of the fibers can be durable and stable.

Owner:旷达纤维科技有限公司 +1

Manufacturing method of beaded polytrifluorochloroethylene resins

The invention relates to a manufacturing method of beaded polytrifluorochloroethylene resins, which comprises the following steps of: taking trifluorochlor oethylene, high-purity water, an organic dispersant and an initiator under the condition that the mass ratio of the trifluorochlor oethylene, the high-purity water, the organic dispersant and the initiator is 100:(500-1000): (50-200): (0.1-1); placing the high-purity water, the organic dispersant and the initiator in a reaction kettle, and at a stirring speed of 400-500 rmp, feeding the trifluorochlor oethylene into the reaction kettle; carrying out reaction on the obtained mixture for 4-6 hours under the conditions of 0.2-1 Mpa and 20-30 DEG C; and then continuing to react for 2-4 hours at a temperature of 50 DEG C and at a stirring speed of 100-200 rmp; and carrying out washing and drying on the obtained product so as to obtain a beaded polytrifluorochloroethylene resin with a diameter of 0.5-5 mm. The method disclosed by the invention is stable in polymerization rate and narrow in molecular weight distribution, no dust flying occurs in the process of production, and no further granulation treatment is required; the obtained polytrifluorochloroethylene resin is excellent in performances, and can be prepared into tubes, bars and profiles with more complicated shapes through melt injection molding; and no yellowing phenomenon occurs, therefore, the method has good social, economic and environmental benefits.

Owner:山东森福新材料有限公司

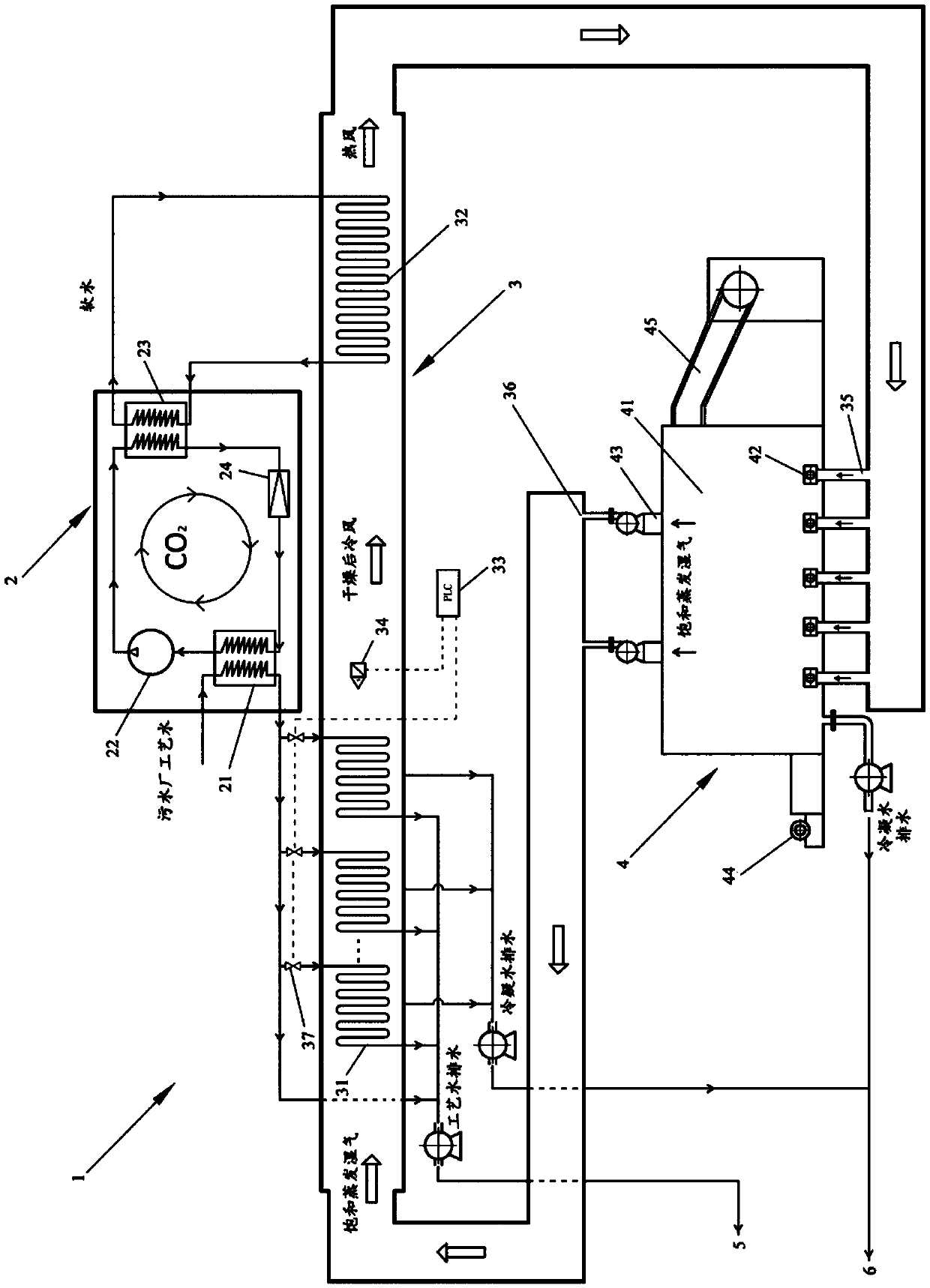

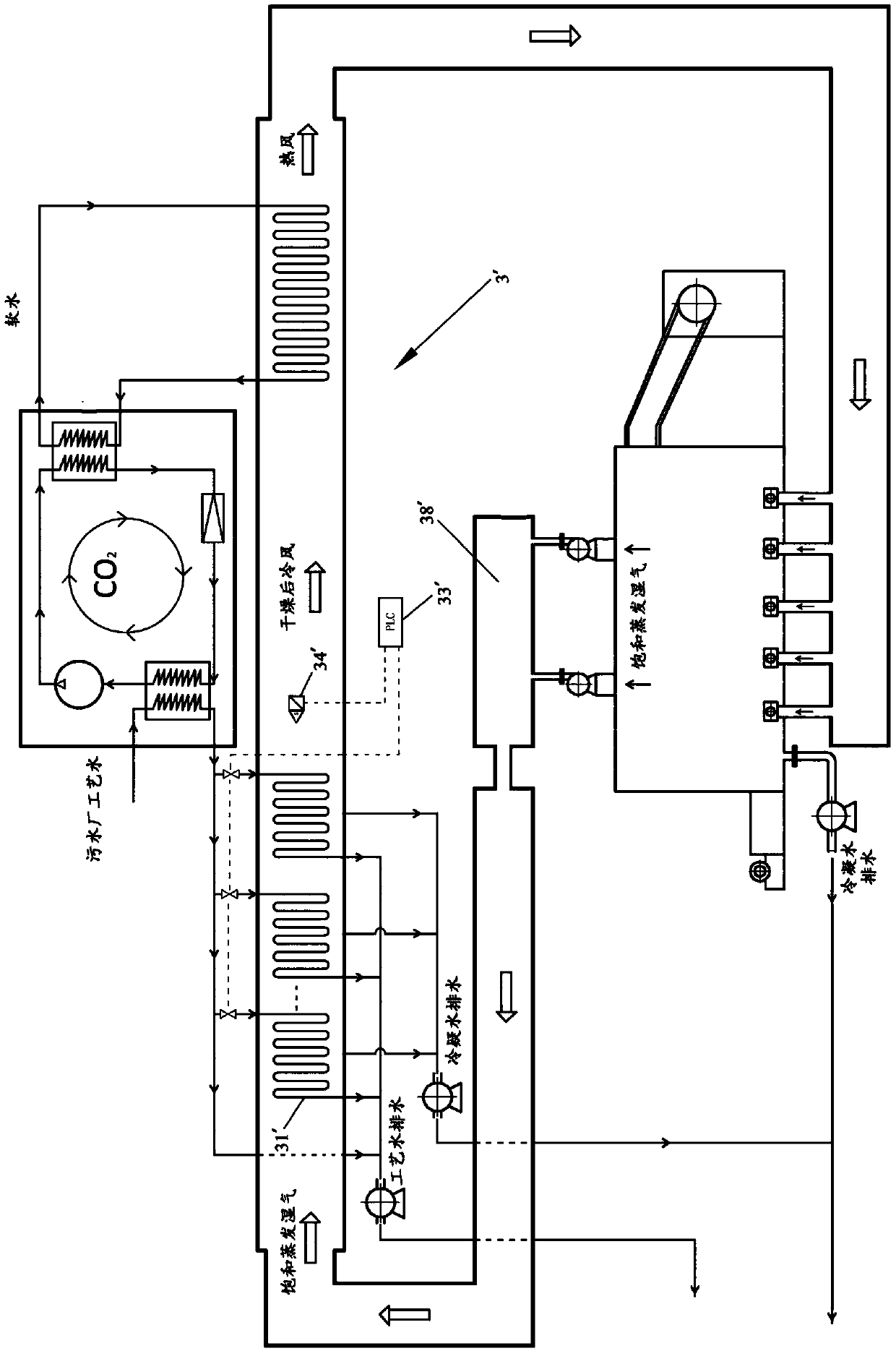

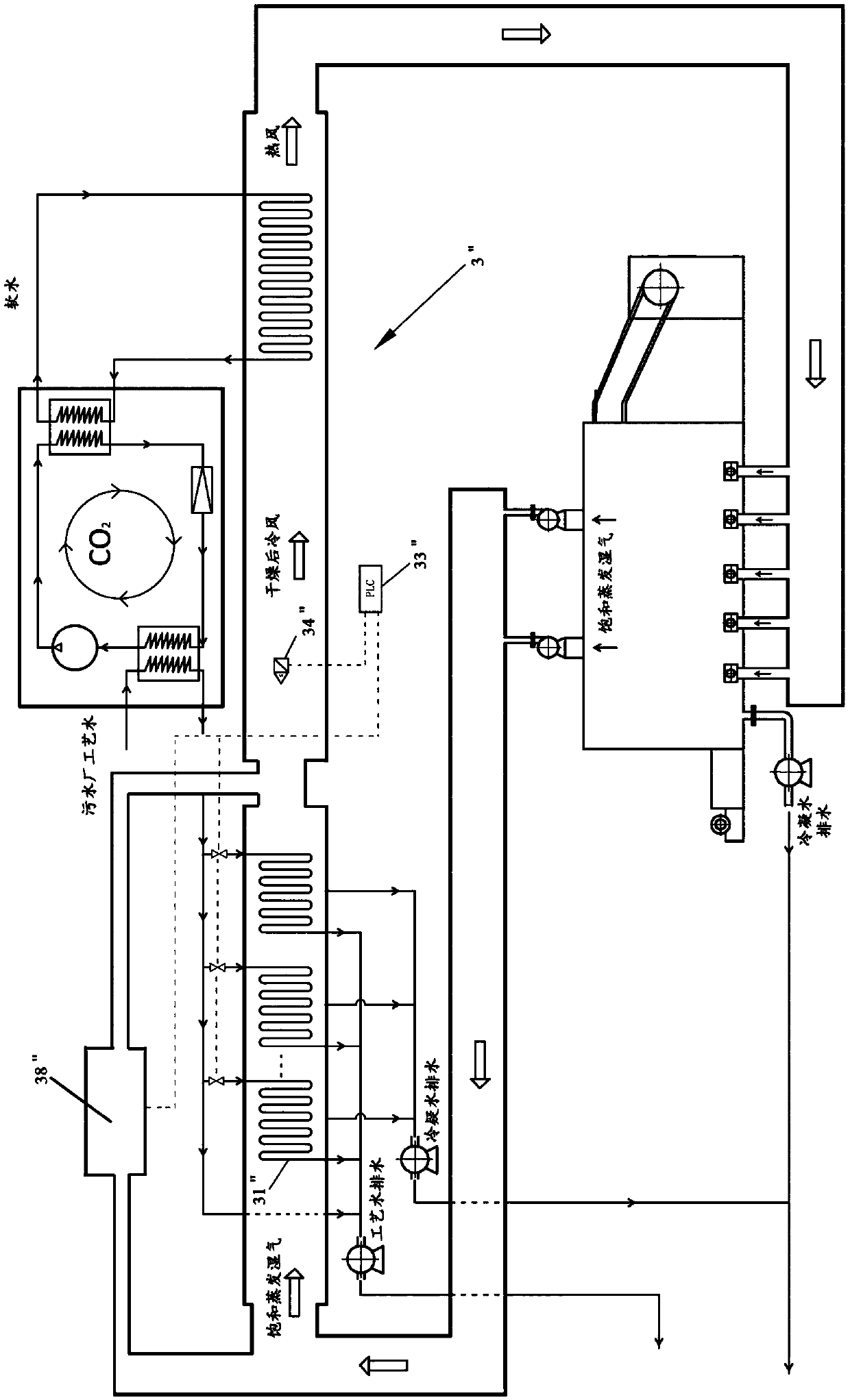

Sludge drying device and sludge drying method

ActiveCN109626791AImplement an infinite loopMultiple Effect EvaporationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesWater treatment systemSludge

The invention relates to a sludge drying device and a sludge drying method. The sludge drying device comprises a heat pump, a drying device and an air adjusting device, wherein process water from a wastewater treatment system is fed into the heat pump; sludge is fed into the drying device to be dried; the air adjusting device is connected to the drying device to form a closed system and used for air for drying the sludge to circularly flow in the closed system. Saturated evaporation moisture generated in the sludge drying process enters the air adjusting device from the drying device, the airadjusting device dehumidifies and dries the saturated evaporation moisture, the dehumidified and dried air is heated by the heat transferring medium which is discharged from an air cooler of the heatpump into hot air, and then the hot air is fed into the drying device to dry the sludge.

Owner:光大清洁技术股份有限公司

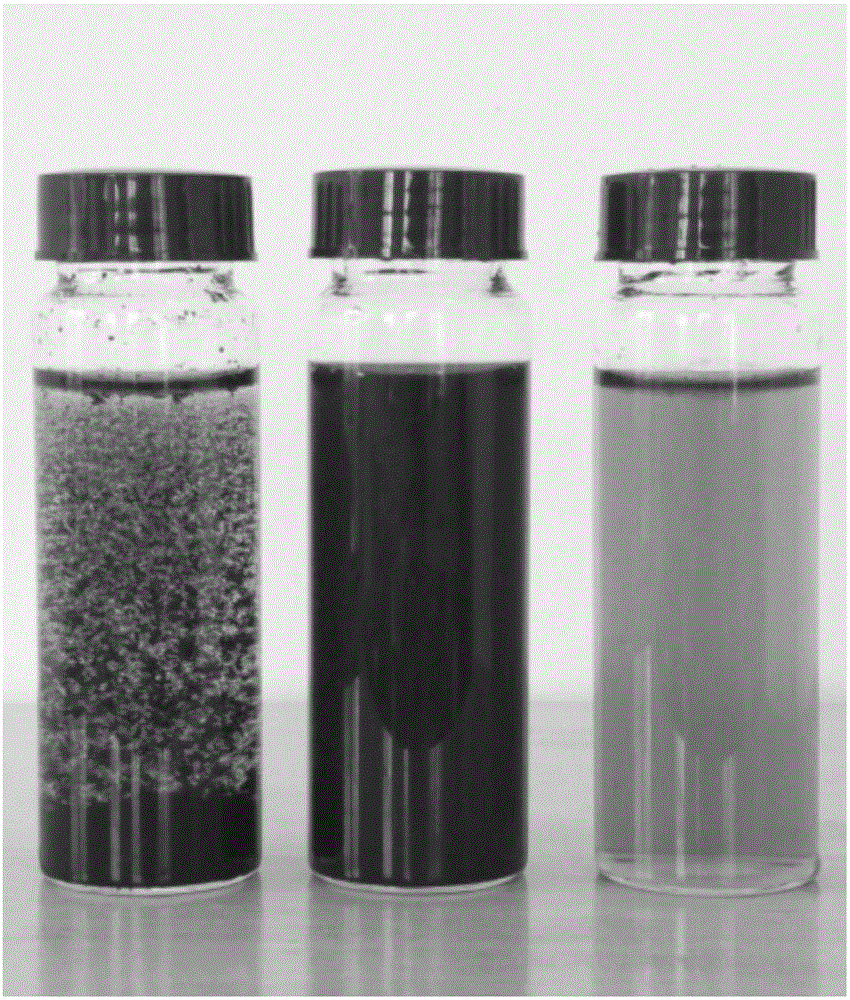

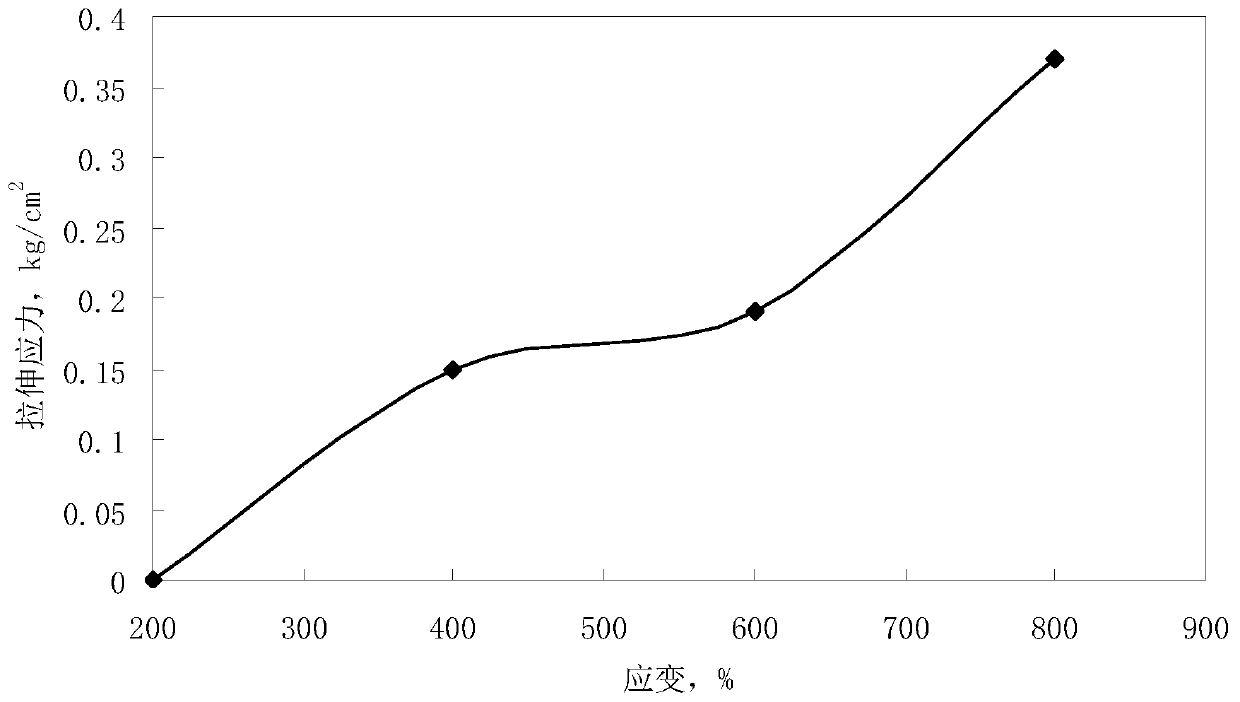

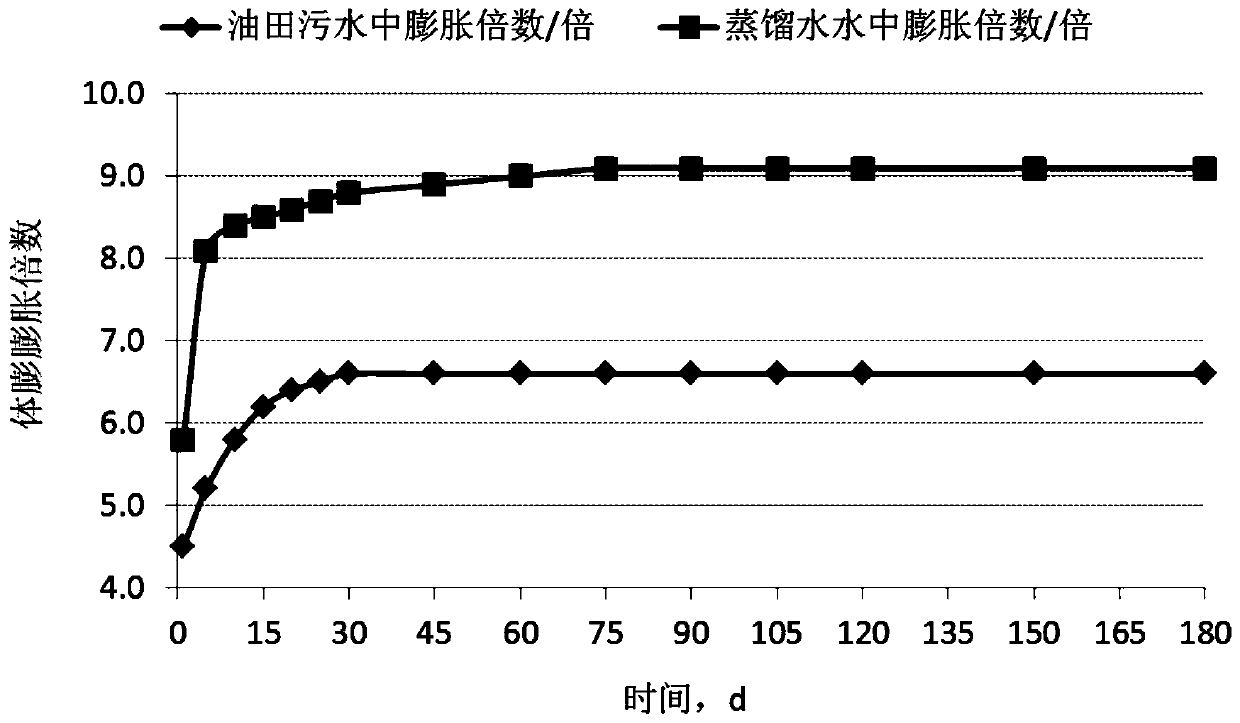

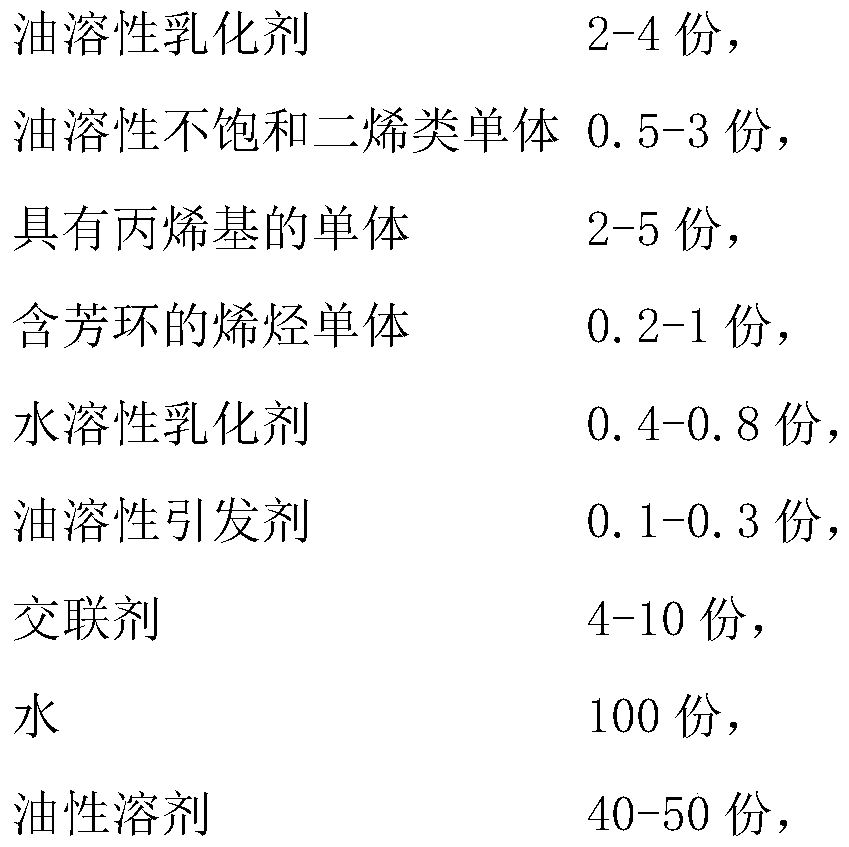

Polymer microsphere modifying and flooding agent for high-temperature and high-salinity oil reservoir as well as preparation method and application thereof

The invention discloses a polymer microsphere modifying and flooding agent for a high-temperature and high-salinity oil reservoir as well as a preparation method and application of the polymer microsphere modifying and flooding agent. The modifying and flooding agent is prepared from an oil-soluble emulsifier, an oil-soluble unsaturated diene monomer, an acrylamide monomer, an aromatic ring-containing olefin monomer, a water-soluble emulsifier, an oil-soluble initiator, a cross-linking agent, water and an oily solvent through water-in-oil-in-water double emulsion polymerization. The polymer microsphere profile modifying and flooding agent prepared by the invention is not easy to degrade in a medium with high mineralization degree, molecules of the modifying and flooding agent do not contain groups easy to hydrolyze, so that the rigidity of a polymer molecular chain is increased, the tackifying, salt resistance and temperature resistance of a polymer are improved, and meanwhile, the polymer microsphere modifying and flooding agent is relatively high in breakthrough pressure gradient, relatively strong in expansibility and relatively good in plugging performance; the preparation process is simple, and drying and granulation processes after the conventional polymer microsphere modifying and flooding agent is prepared are omitted.

Owner:成都新驱势石油技术开发有限公司

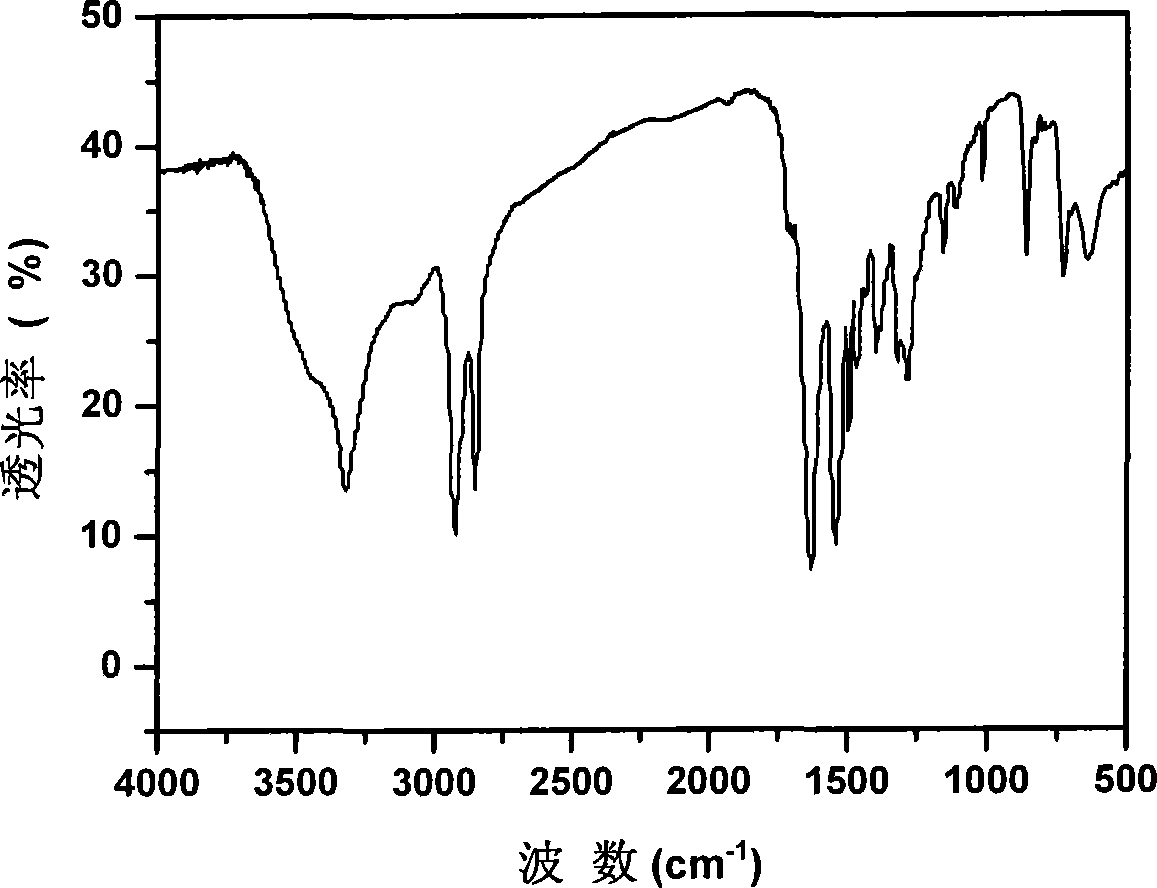

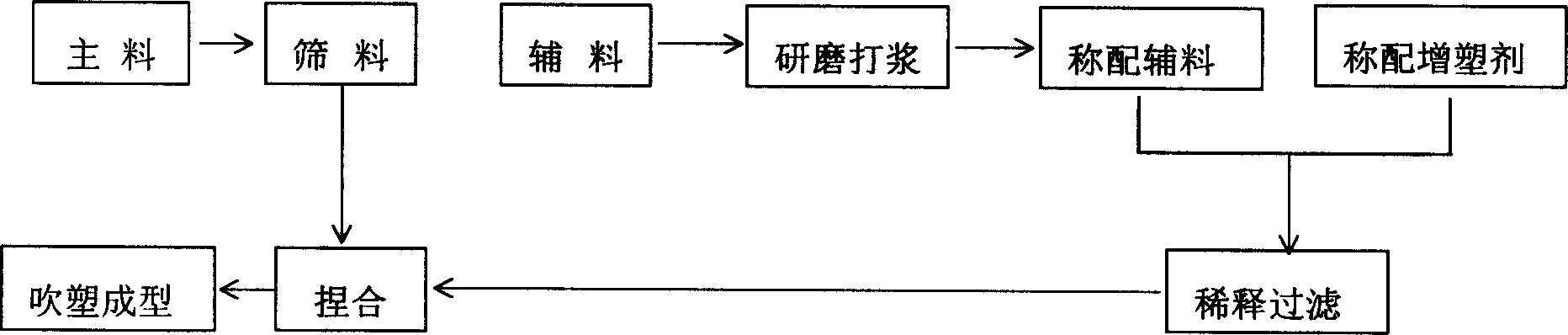

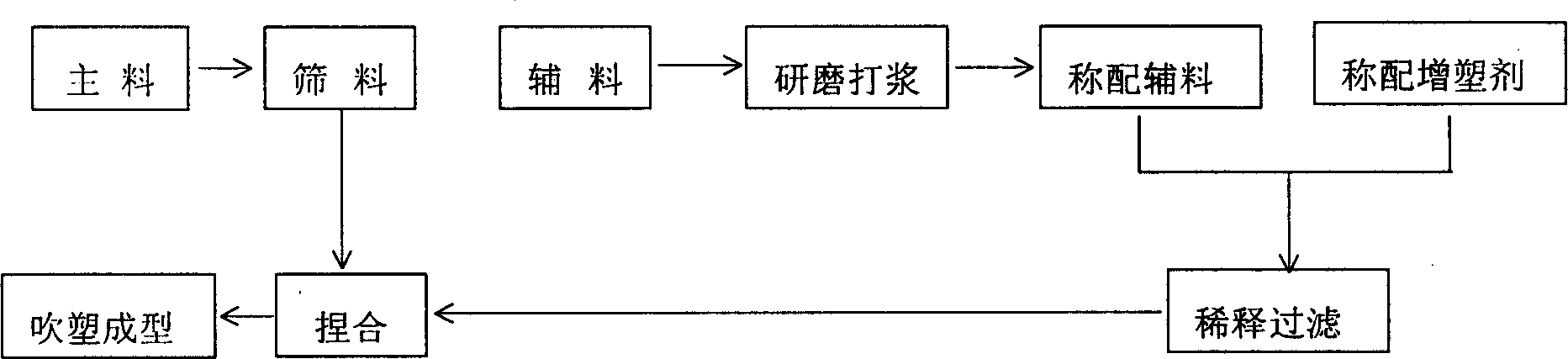

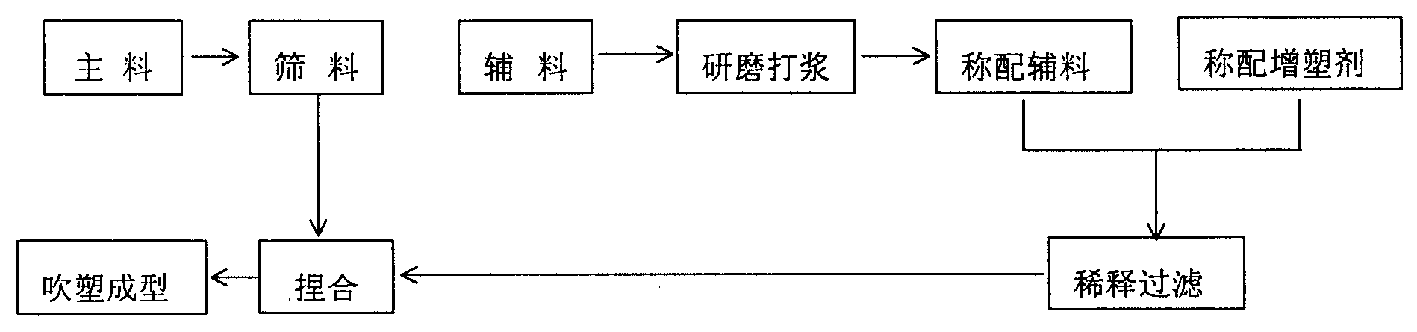

Dedicated film (bag) for keeping tender garlic fresh and fabricating method

InactiveCN1539876ASimple production processEasy to operate and masterFruit and vegetables preservationEpoxyParaffin wax

An antistaling film (bag) for fresh garlic cloves is prepared from polyvinyl chloride resin, dioctyl phthalate, dioctyl decanedionate, octyl epoxy soybean oleate, phosphite, calcium stearate, zinc stearate, stearic acid, paraffin wax and nano-class active calcium carbonate through proportionally mixing, high-temp kneading, single-screw extruding out and blow moulding.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN +1

Method for preparing semi-aromatic nylon

ActiveCN101768266BLow reaction temperatureReduce energy consumptionMaterial synthesisRoom temperature

The invention discloses a method for preparing semi-aromatic nylon and belongs to the technical field of macromolecular material synthesis. The method comprises the following steps: (1) uniformly mixing aliphatic diamine and water of which the weight is two to ten times that of the aliphatic diamine, heating the mixture to the temperature of between 50 and 90 DEG C, adding aromatic diacid into the mixture with stirring till a pH value of the solution reaches 7.0-7.7, continuously stirring for 1 to 5 hours, cooling the solution to room temperature, continuously stirring the solution for 1 to 5hours again, and filtering and drying to obtain nylon salt for later use; and (2) adding the prepared nylon salt and a solvent to a polymerization kettle in a certain mixture ratio (0.5 to 3.0 g / mL),raising the temperature to between 190 and 230 DEG C under the protection of inert gas, keeping the pressure in the kettle between 2.0 and 3.0 MPa, discharging gas after 1 to 5 hours to make the pressure in the kettle reduced to normal pressure within 1 to 5 hours, raising the temperature to between 210 and 270 DEG C, and continuing to react for 1 to 5 hours, and discharging to obtain a powdery semi-aromatic nylon product. The method has mild reaction condition and low energy consumption; the product is easy to mold and machine; and the method solves the difficult problem of difficult discharging of the semi-aromatic nylon, and is applicable to industrialized production.

Owner:青岛智库生物技术有限公司

Cleaning agent for screw rod of plastic extruding machine or injection molding machine

The invention relates to a cleaning agent for a screw rod of a plastic extruding machine or an injection molding machine. The cleaning agent is used for cleaning a machine barrel and a screw rod of the extruding machine or the injection molding machine. The cleaning agent consists of the following components: 25 to 40 percent of a hard cleaning agent glass fiber, 5 to 10 percent of an interface cleaning agent PPA and 50 to 70 percent of matrix resin. The cleaning agent provided by the invention has the advantages of cleaning various adhering substances on the surface of the machine barrel and the screw rod quickly, strongly and efficiently, and greatly improving the cleaning efficiency, and is low in cost.

Owner:SHANGHAI WEIXING NOVEL BUILDING MATERIAL

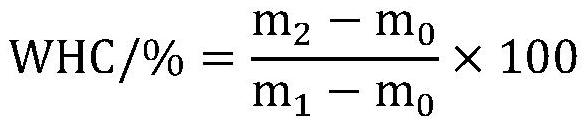

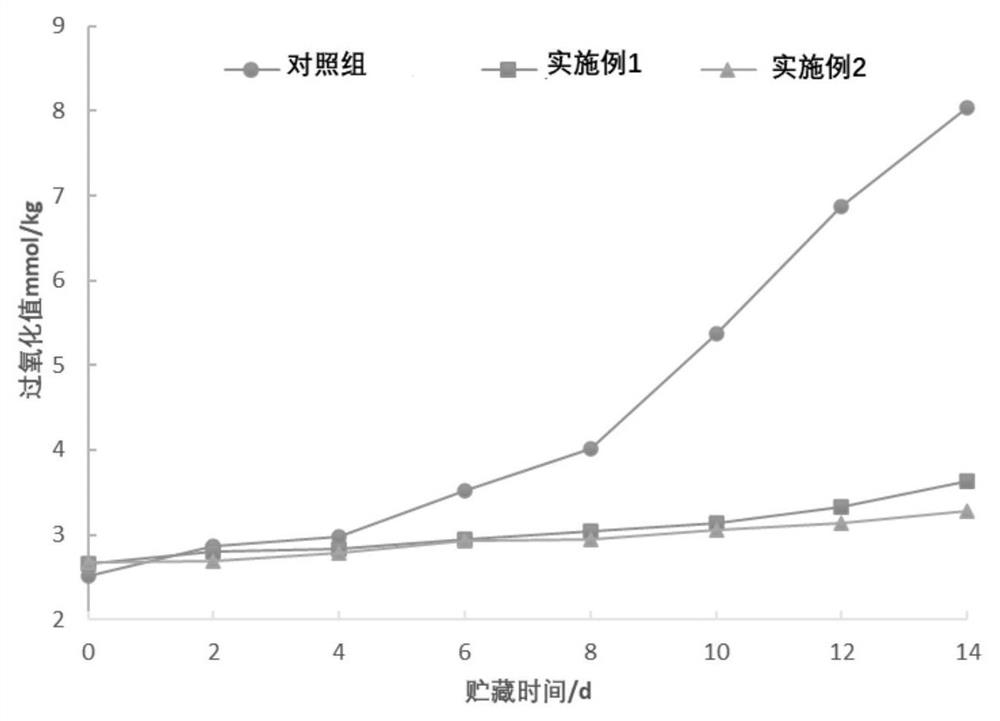

Meal aid suitable for preparing vegetable type easy-to-eat food for old people and application of meal aid

PendingCN112704216AFood safetySimple ingredientsFood ingredient as thickening agentFood ingredient as gelling agentBiotechnologyOlder people

The invention relates to easy-to-eat food for old people, in particular to a meal aid suitable for preparing vegetable type easy-to-eat food for old people and application of the meal aid. The meal aid suitable for preparing the vegetable type easy-to-eat food for the old people is prepared from the following components in parts by weight: 35-87 parts of gel colloid and 9-72 parts of thickening colloid. The combined action of the gel colloid and the thickening colloid in the meal aid can significantly improve the water-holding capacity and hardness of the easy-to-eat food for the old people prepared from vegetables as main materials, the easy-to-eat food for the old people is maintained good appearance and taste, so that the ingestion safety of the old people is improved, and the appetite of the old people is stimulated.

Owner:北京市营养源研究所有限公司

Macadamia nut tea and preparation method thereof

The invention discloses macadamia nut tea and a preparation method thereof. The macadamia nut tea is prepared from the following raw materials in parts by weight: 80-100 parts of macadamia nut kernels, 30-80 parts of maltodextrin, 40-100 parts of cane sugar, 40-80 parts of milk powder, 1-6 parts of tea leaves, 1-6 parts of an emulsifier, 0.1-1 part of a food flavor and 0.1-1 part of food-grade silicon dioxide. According to the macadamia nut tea and the preparation method thereof, the macadamia nut tea product which is good in solubility, more stable in fat in the product, unique in flavor of nuts and tea fragrance and smooth in taste is prepared through a special formula and a special process. The obtained product is convenient to brew and easy to carry and store, product marketization is achieved, and the product is suitable for being industrially popularized and applied. According to the macadamia nut tea and the preparation method thereof, a processing way of macadamia nuts is widened, the additional value is increased, and the macadamia nut tea and the preparation method thereof have an important significance in healthy development of macadamia nut industry and poverty-overcoming and prosperity-becoming of farmers.

Owner:JILIN UNIV +1

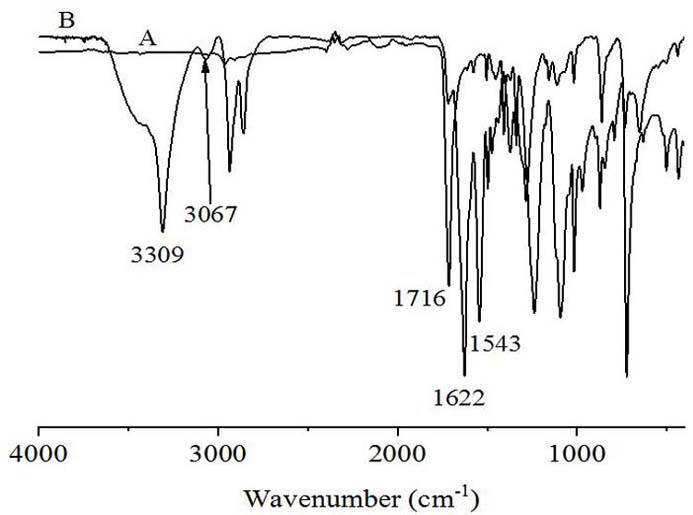

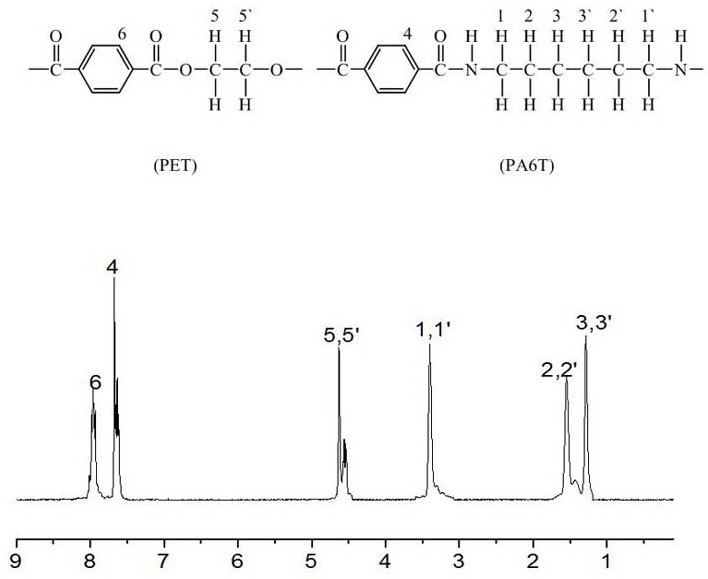

Method for preparing high-temperature-resistant nylon by utilizing amidation reaction of polyester

PendingCN113429571AImprove heat resistance and physical mechanical propertiesStable physical and mechanical propertiesDiamineAuto industry

The invention belongs to the field of preparation of nylon, and particularly relates to a method for preparing high-temperature-resistant nylon by utilizing an amidation reaction of polyester. The preparation method comprises the following steps of: adding a macromolecular polyester raw material and diamine into a solvent, heating to a heat preservation temperature, reacting, and washing the obtained product to obtain the high-temperature-resistant nylon. The preparation method is mild in reaction condition and simple in process, the used solvent can be recycled, and the cost is relatively low. Meanwhile, recycled polyester can be used as a reaction raw material in the method, so that the waste polyester plastic can be converted into another high-added-value product while the white pollution is reduced, and the waste is turned into wealth. The obtained product has stable physical and mechanical properties and excellent quality, can be widely applied to the fields of automobile industry, electronic and electrical industry, mechanical industry and the like, and is a new material with good application prospects.

Owner:ZHENGZHOU UNIV

Dedicated film (bag) for keeping tender garlic fresh and fabricating method

InactiveCN1244627CSimple production processEasy to operate and masterFruit and vegetables preservationEpoxyParaffin wax

An antistaling film (bag) for fresh garlic cloves is prepared from polyvinyl chloride resin, dioctyl phthalate, dioctyl decanedionate, octyl epoxy soybean oleate, phosphite, calcium stearate, zinc stearate, stearic acid, paraffin wax and nano-class active calcium carbonate through proportionally mixing, high-temp kneading, single-screw extruding out and blow moulding.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN +1

High temperature resistant polylactic acid melt-blown electret nonwoven filter material and its preparation method and application

ActiveCN108708079BNo granulation requiredSimple production processHeating/cooling textile fabricsUltrasonic/sonic fibre treatmentPolymer scienceFilter material

The invention provides a high-temperature-resistant polylactic acid melt-blown electret nonwoven filter material and its preparation method and application. Corona electret treatment. The material prepared by the method does not need to add any functional additives, and does not need to be granulated, which simplifies the production process.

Owner:上海精发实业有限公司

A kind of preparation method of polyester fiber with catalytic degradation function

ActiveCN106544858BNo granulation requiredSimple preparation processFibre typesDispersed particle separationPolyesterFiber

Owner:旷达纤维科技有限公司 +1

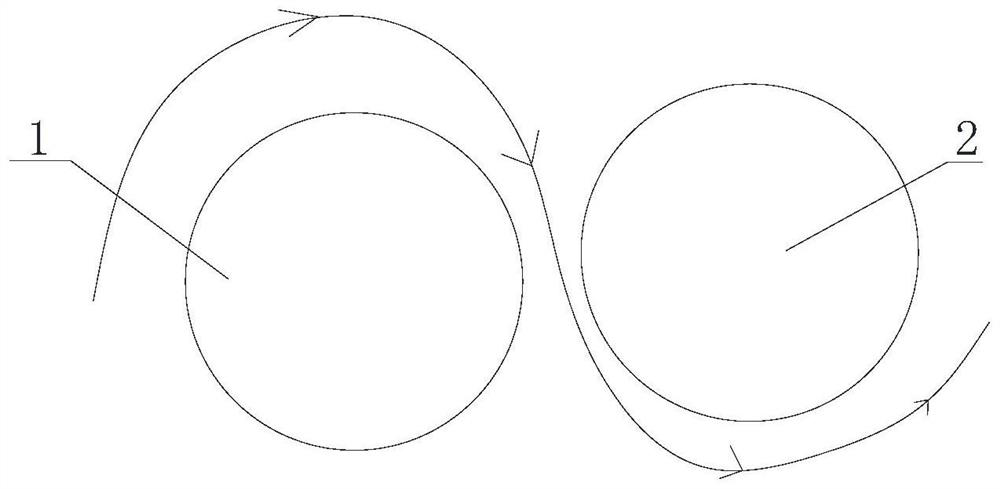

Polyvinyl alcohol hollow container preparation method

ActiveCN100553940CNo granulation requiredExtrusion-free granulationHollow articlesBlow moldingPolymer science

The invention discloses a preparation method of a polyvinyl alcohol hollow container, which is characterized in that 1 to 25 parts of a modifying agent having a complementary structure with polyvinyl alcohol are dissolved in 20 to 50 parts of deionized water, stirred to form a uniform solution, and then 50 parts of ~80 parts of polyvinyl alcohol, fully swell at a temperature of 20~60°C, add 0~5 parts of auxiliary additives, mix evenly, and blow on the blow molding equipment at a thermoplastic processing temperature of 60~170°C and a mold temperature of 10~150°C Molded into a hollow container, then undergo heat treatment at a temperature of 40-250°C or infrared drying for 3-120 minutes to increase the crystallinity of the product, or cross-link with a cross-linking agent solution with a concentration of 0.1%-5% at a temperature of 20-80°C After 1 to 60 minutes, heat treatment or infrared drying is performed to obtain a polyvinyl alcohol hollow container with excellent barrier properties, mechanical properties and moisture resistance.

Owner:SICHUAN UNIV

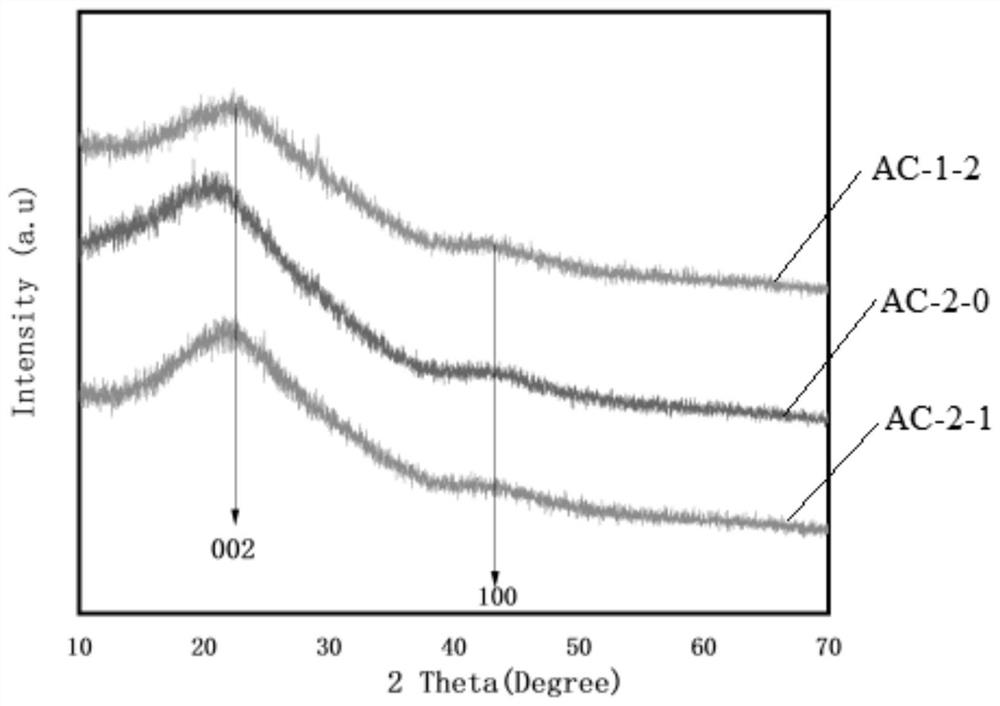

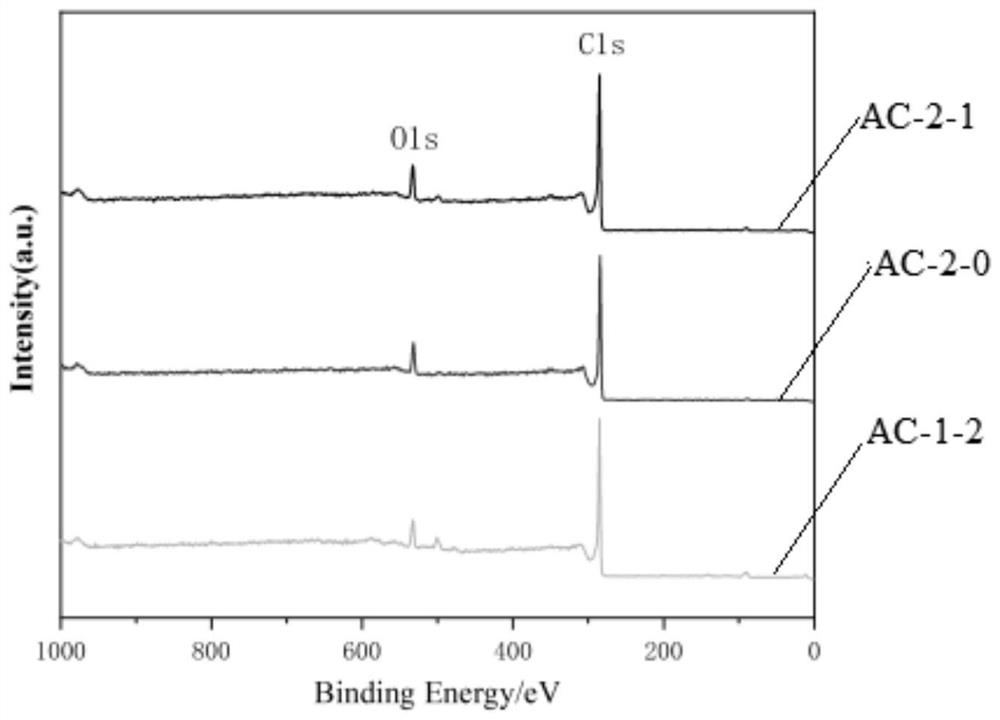

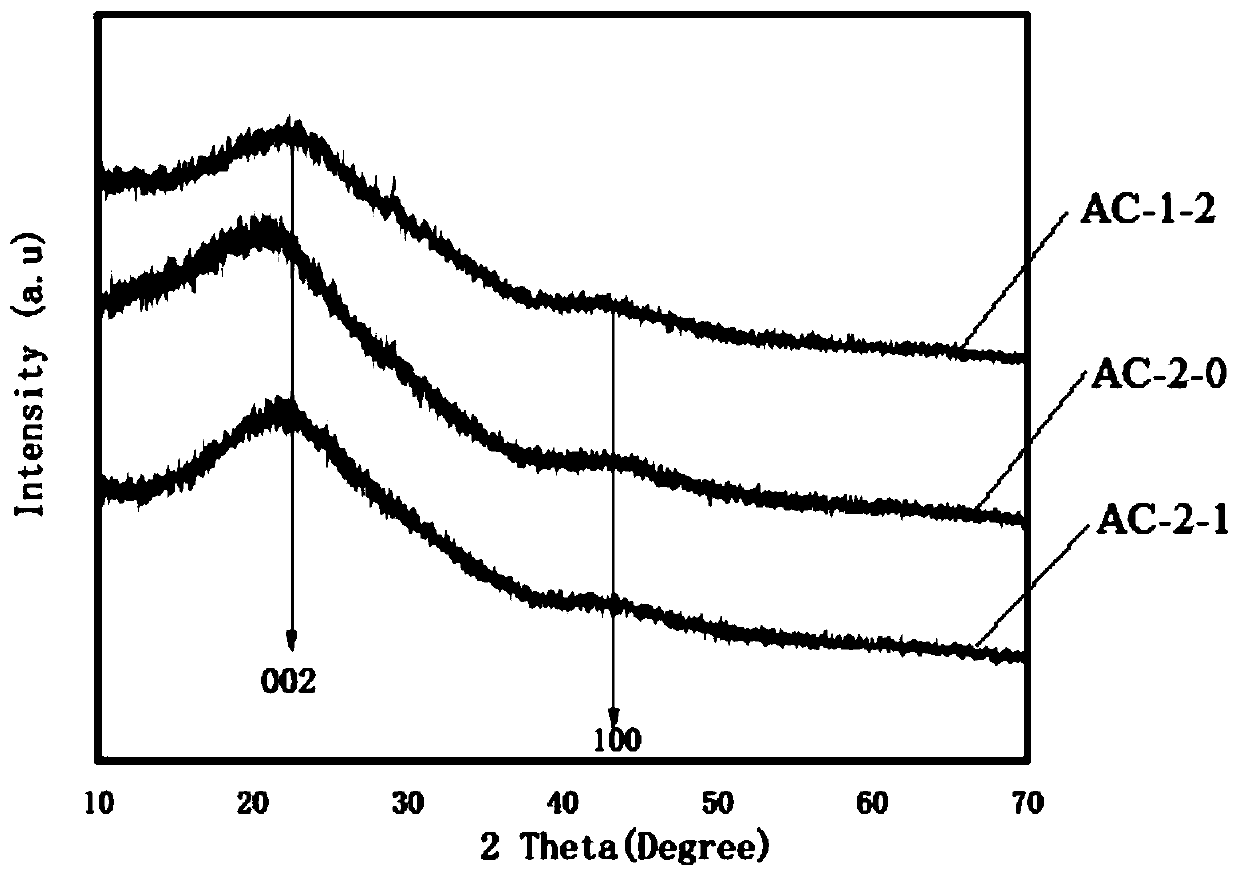

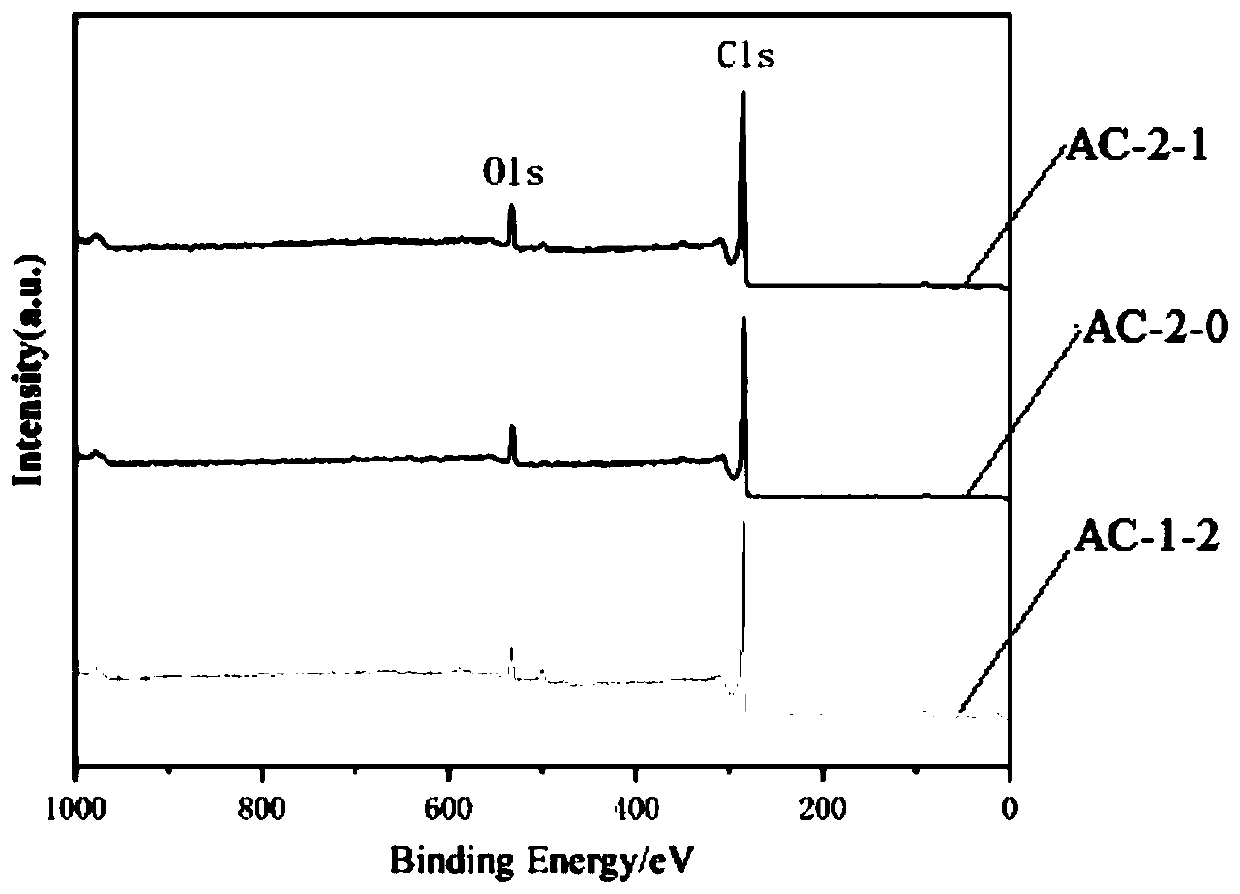

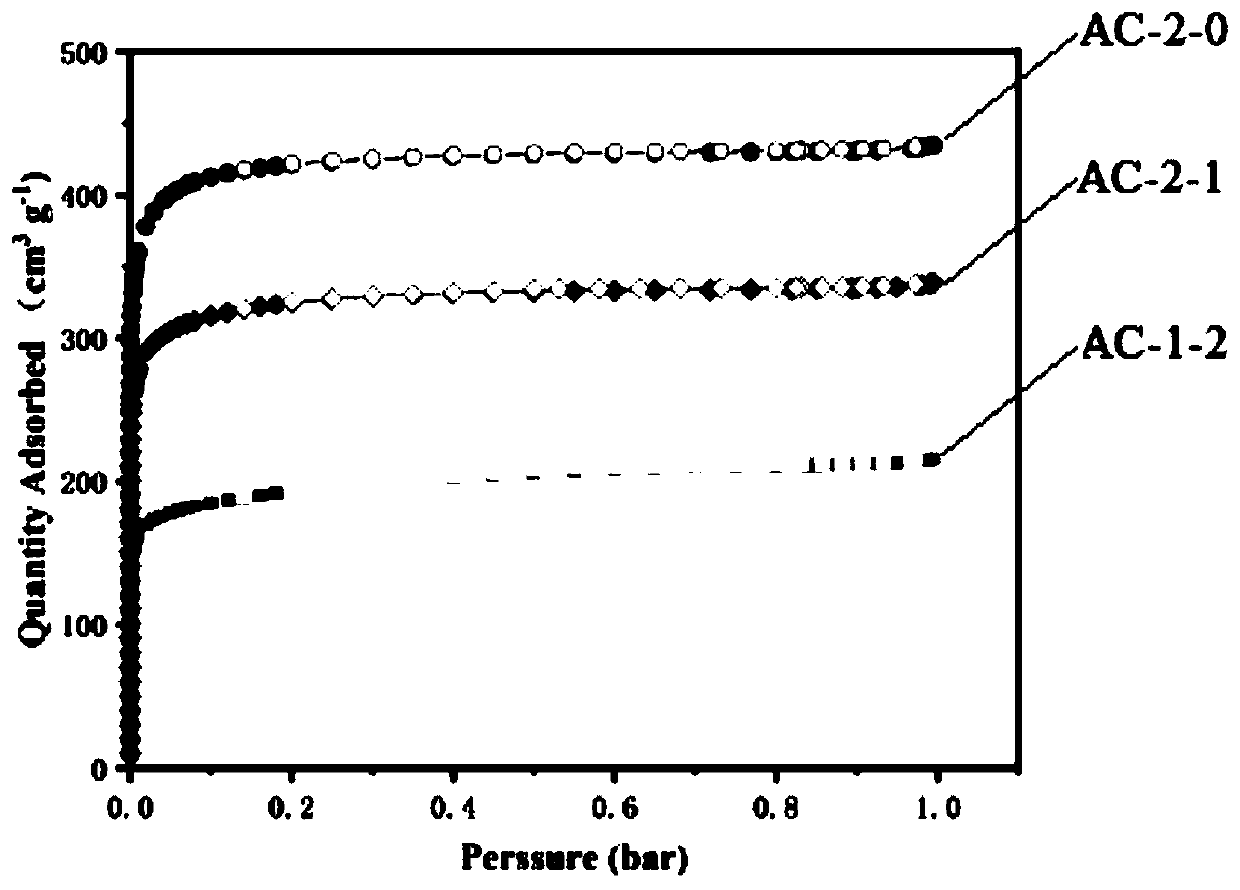

An integrally formed granular carbon adsorbent and its preparation method and application

ActiveCN111530423BEasy to makeLow costOther chemical processesGaseous fuelsEconomic benefitsAdsorption selectivity

Owner:NANCHANG UNIV

A plastic extruder or injection molding machine screw cleaning agent

The invention relates to a cleaning agent for a screw rod of a plastic extruding machine or an injection molding machine. The cleaning agent is used for cleaning a machine barrel and a screw rod of the extruding machine or the injection molding machine. The cleaning agent consists of the following components: 25 to 40 percent of a hard cleaning agent glass fiber, 5 to 10 percent of an interface cleaning agent PPA and 50 to 70 percent of matrix resin. The cleaning agent provided by the invention has the advantages of cleaning various adhering substances on the surface of the machine barrel and the screw rod quickly, strongly and efficiently, and greatly improving the cleaning efficiency, and is low in cost.

Owner:SHANGHAI WEIXING NOVEL BUILDING MATERIAL

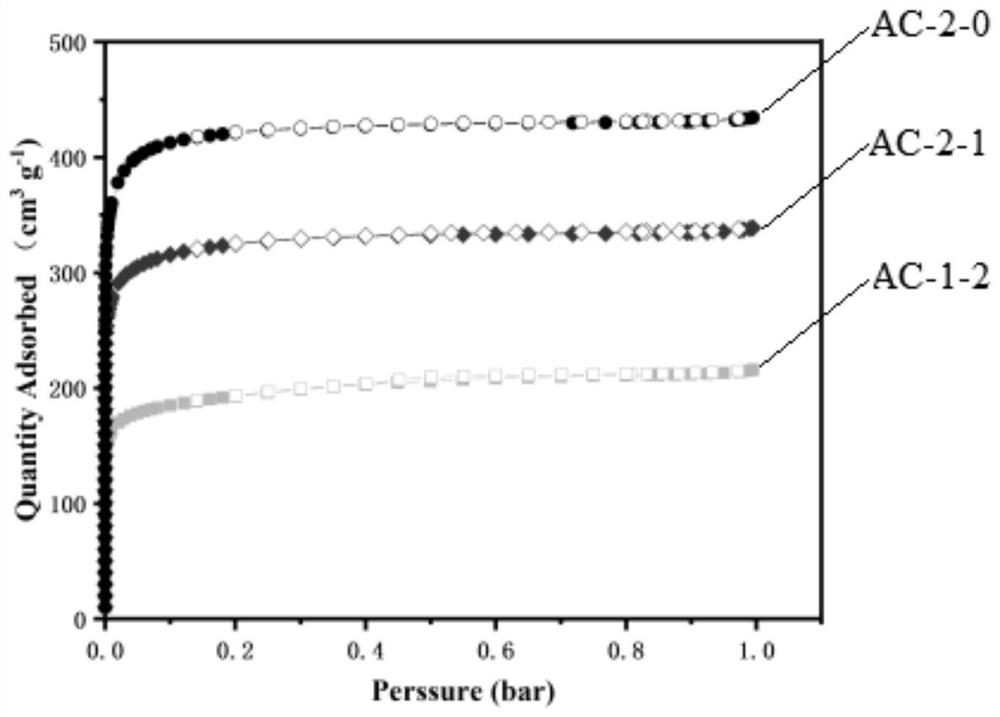

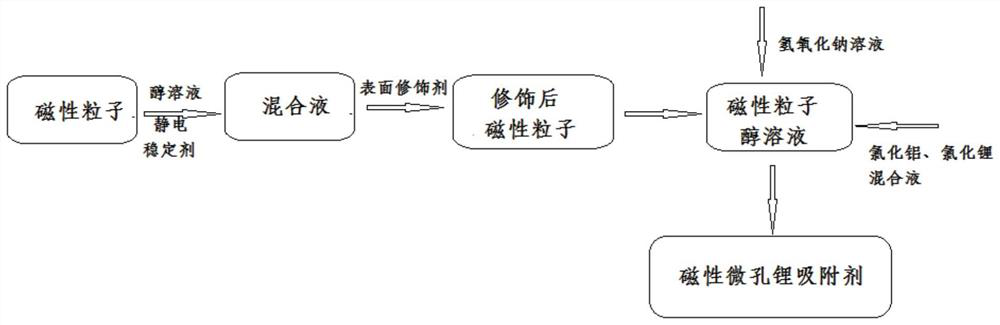

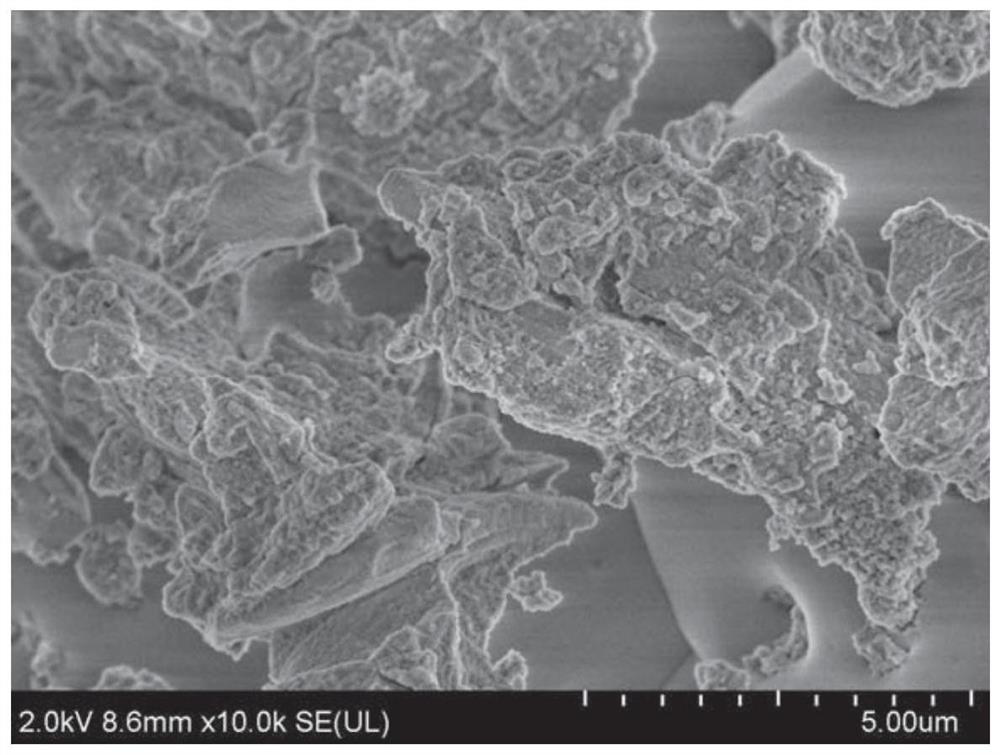

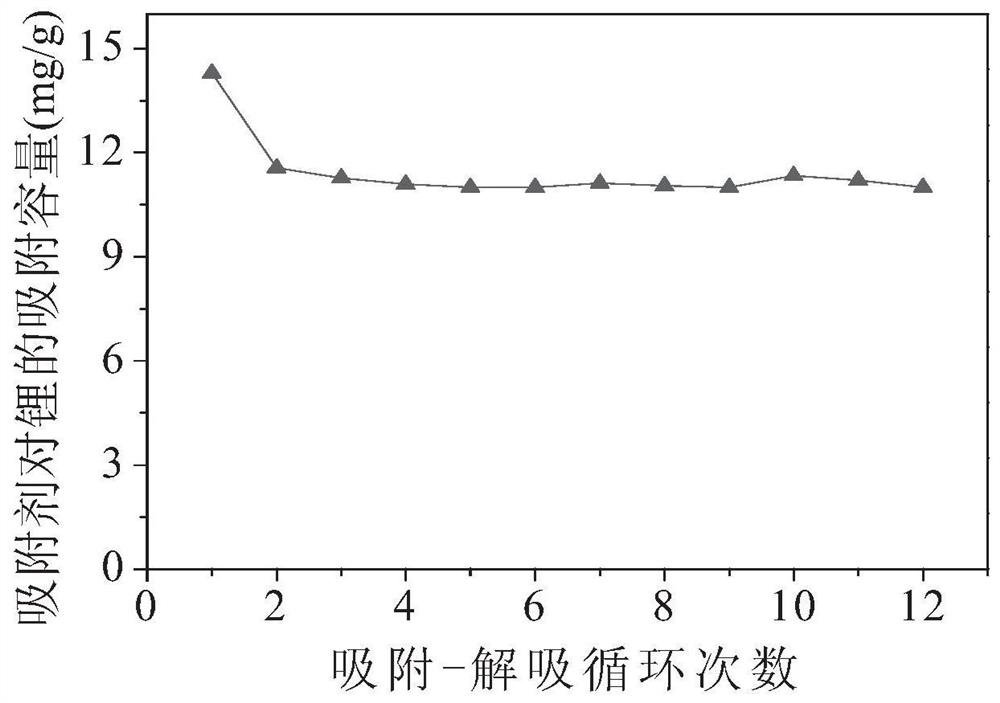

Magnetic microporous lithium adsorbent and its preparation method and application

The invention discloses a preparation method of a magnetic microporous lithium adsorbent, which comprises: modifying the surface of a magnetic material with a surface modifier to obtain a surface-modified magnetic material; The alcohol dispersion liquid of the modified magnetic material is reacted to prepare the magnetic microporous lithium adsorbent. The present invention can better control the specific surface area and pore size distribution of the adsorbent by controlling the drop rate of the soluble lithium salt and the pH of the reaction end point to obtain a microporous lithium adsorbent; after modifying the surface of the magnetic material, the lithium adsorbent can be stabilized grafted on the surface of the magnetic material to obtain a microporous magnetic lithium adsorbent. The adsorbent has magnetic properties, is convenient for solid-liquid separation in the adsorption-desorption process, does not require granulation, is loose and porous, has a large specific surface area, and has obvious advantages in static adsorption capacity and dynamic working adsorption capacity.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Preparation method of modified polytrifluorochloroethylene resin

The invention discloses a preparation method of modified polytrifluorochloroethylene resin. The preparation method comprises the following steps of: weighing the following components: trifluorochloroethylene, high-purity water, a hydrophobic polymer dispersant, an initiator and a surfactant; adding the chlorotrifluoroethylene, the high-purity water and the hydrophobic polymer dispersant into a reaction kettle for primary dispersion; adding the surfactant into obtained dispersion liquid, and carrying out secondary dispersion; and adding the high-purity water and the initiator into obtained secondary dispersion liquid to continue the reaction, and washing and drying an obtained product to obtain the polytrifluorochloroethylene resin. According to the preparation method of the modified polytrifluorochloroethylene resin of the invention, the surfactant is added into the dispersion liquid in the preparation process, so that odor emitted by a dispersion medium during water absorption can be effectively reduced, the added oil-soluble redox initiator can ensure that the chain propagation reaction of the trifluorochloroethylene is carried out at a uniform speed in an oil phase, then polytrifluorochloroethylene resin is separated out, and granulation is not needed in the later period.

Owner:UNIV OF JINAN

Method of producing three-in-one electrode of solid oxide fuel battery

InactiveCN101183716BGuaranteed uptimeMeet the preparation requirements of porousElectrolyte holding meansLiquid surface applicatorsSurface engineeringInternal resistance

The invention relates to a preparation method of membrane electrode assembly of solid oxide fuel cell, belonging to the plasma spraying method in the surface engineering area for the preparation of the core parts of the solid oxide fuel cell. The invention aims at preparing a compact electrolyte layer with smaller film thickness and evenly distributed material composition, effectively improving the electrolyte conductivity, reducing the internal resistance of SOFC, increasing the output power, and preparing porous and evenly distributed electrodes. The invention comprises following steps: preparation, spraying a support electrode, spraying an electrolyte layer, spraying cathode or anode. The invention has the advantages that fine nanometer or ultrafine powder can be directly used to spraywithout granulating; the material change between the function layers shows continuous gradually-changing gradient distribution, which can reduce the interface resistance and avoid the interface stratification; one time continuous forming is integrated with sintering process, and times of sintering are not needed, so that the invention is particularly suitable for spraying SOFC electrodes in the forms of flat plate, tuber, Mono-Block Layer Built and corrugating, large-area nanostructure coating, and short process making of nanometer devices.

Owner:HUAZHONG UNIV OF SCI & TECH

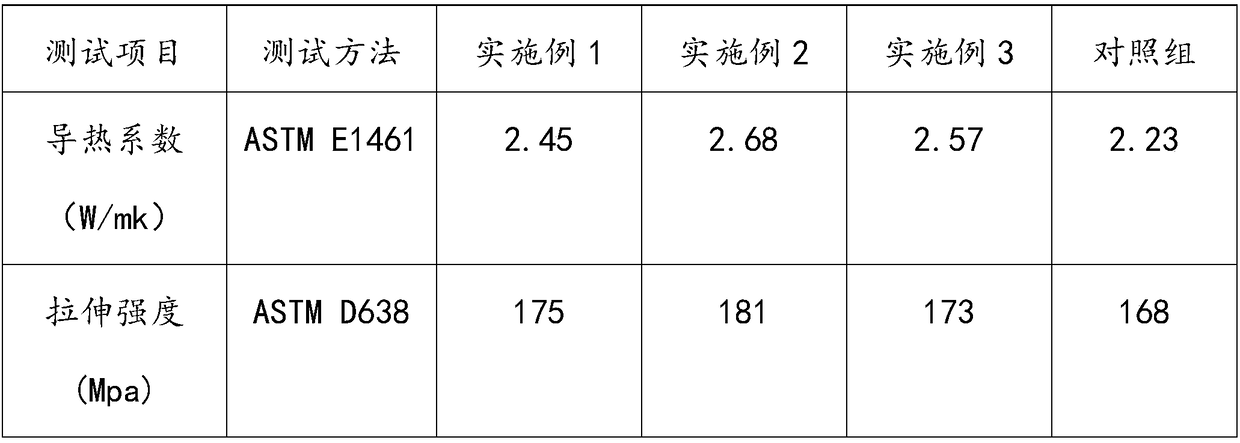

Abrasion-resistant LED heat dissipation lamp holder and preparation method thereof

InactiveCN109401284AGood heat dissipationImprove mechanical strength and wear resistanceBrominePolypropylene

The invention relates to the technical field of LED lamp production, and discloses an abrasion-resistant LED heat dissipation lamp holder and a preparation method thereof. The abrasion-resistant LED heat dissipation lamp holder is prepared from the following raw materials in parts by weight: 60-90 parts of polyamide resin, 40-60 parts of polypropylene resin, 5-9 parts of a toughening agent, 15-20parts of an asbestos fiber, 3-6 parts of high alumina bauxite, 0.4-0.7 part of an antioxidant, 0.3-0.8 part of a lubricant, and 0.2-0.5 part of a dispersant. The LED lamp holder has good heat dissipation, abrasion resistance, flame retardancy, safety and environmental protection; polyamide resin and polypropylene resin which are heat conducting materials are taken as main raw materials; the asbestos fiber and the high alumina bauxite are added; on the premise of ensuring good heat dissipation, the mechanical strength and abrasion resistance of the LED lamp holder can be effectively improved; meanwhile, the use of toxic and harmful raw materials containing bromine and heavy metals is reduced; and compared with traditional aluminum lamp holders and ceramic lamp holders, the LED lamp holder prepared by direct injection molding of mixed powder has simple process and low costs.

Owner:河南恒翔塑业科技有限公司

Integrally formed granular carbon adsorbent as well as preparation method and application thereof

ActiveCN111530423AProtection separationApplications in protection of methane enrichmentOther chemical processesGaseous fuelsCamellia oleiferaPhysical chemistry

The invention relates to the technical field of adsorbents, in particular to an integrally-formed granular carbon adsorbent as well as a preparation method and application thereof. The granular carbonadsorbent is prepared by taking camellia oleifera shells as a raw material, performing pre-carbonization, performing pore-forming under an optimized KOH and ZnCl2 mixing condition, and finally performing sintering. According to the granular carbon adsorbent prepared by the method, the use of a binder is avoided, the integrally-formed granular carbon material with high mechanical strength is prepared at low cost, efficient CH4 / N2 separation and methane enrichment are realized, the problem of energy shortage can be relieved, and economic benefits are created; and under the conditions of 298 K and 100 kPa, the CH4 absorption amount of the prepared granular carbon adsorbent is as high as 1.49 mmol / g, and the CH4 / N2 adsorption selectivity is as high as 5.88.

Owner:NANCHANG UNIV

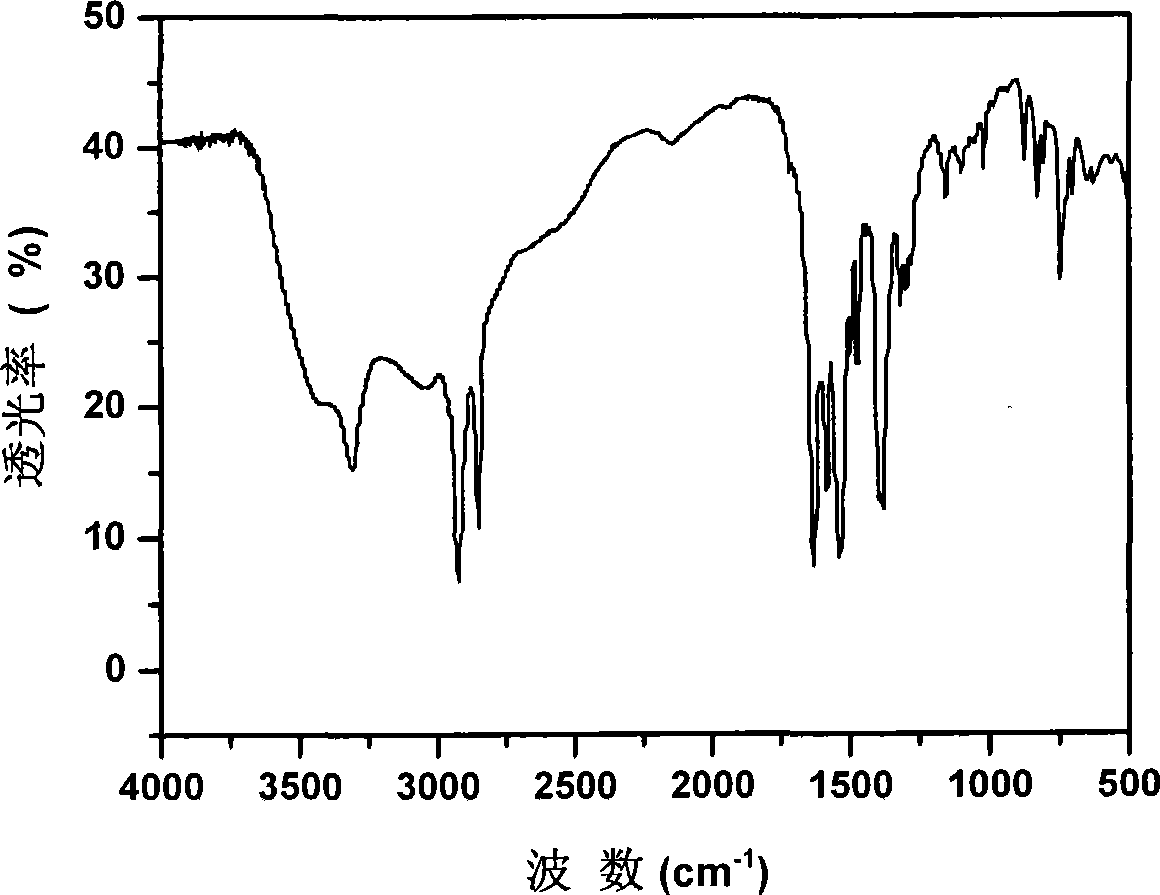

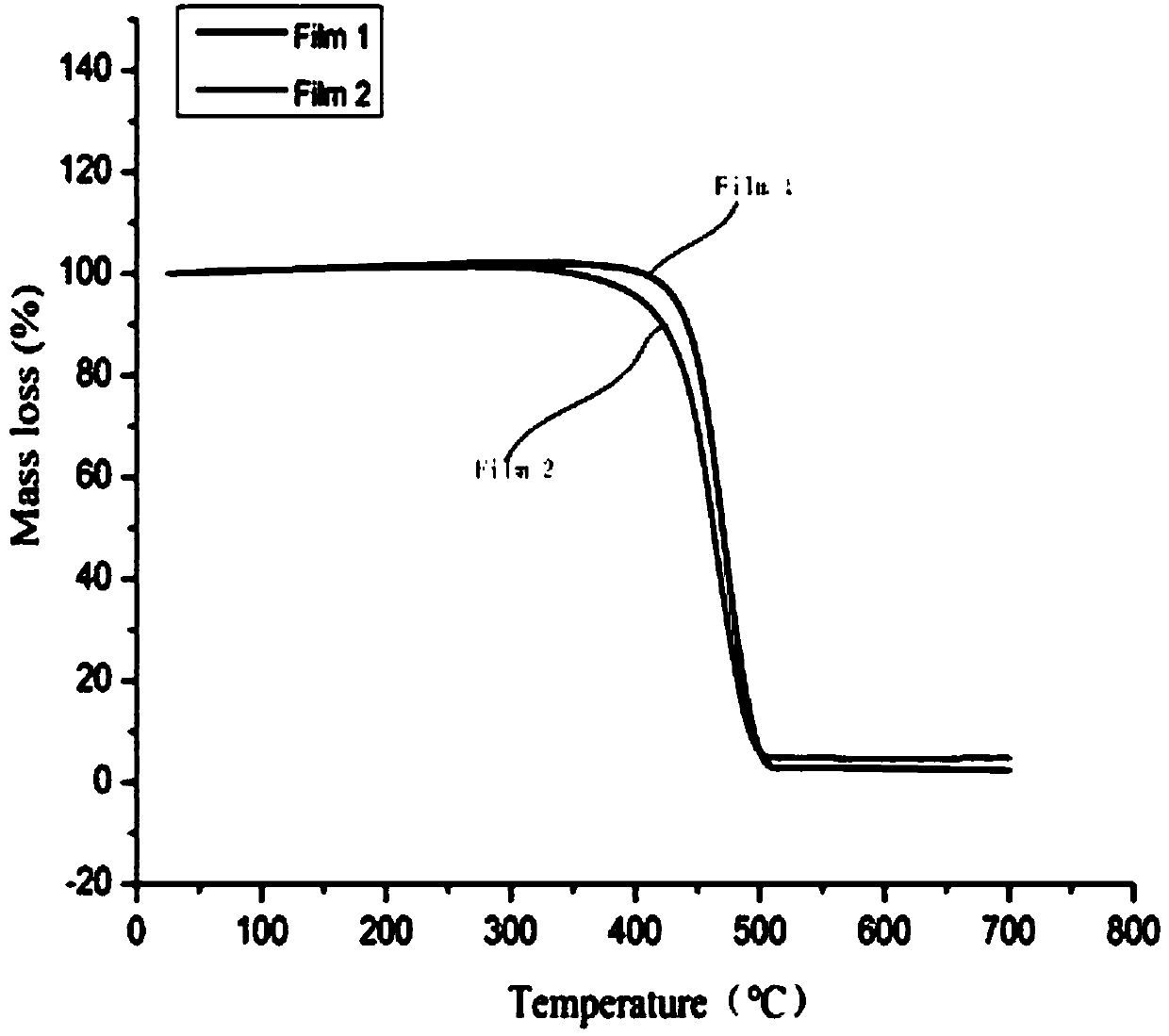

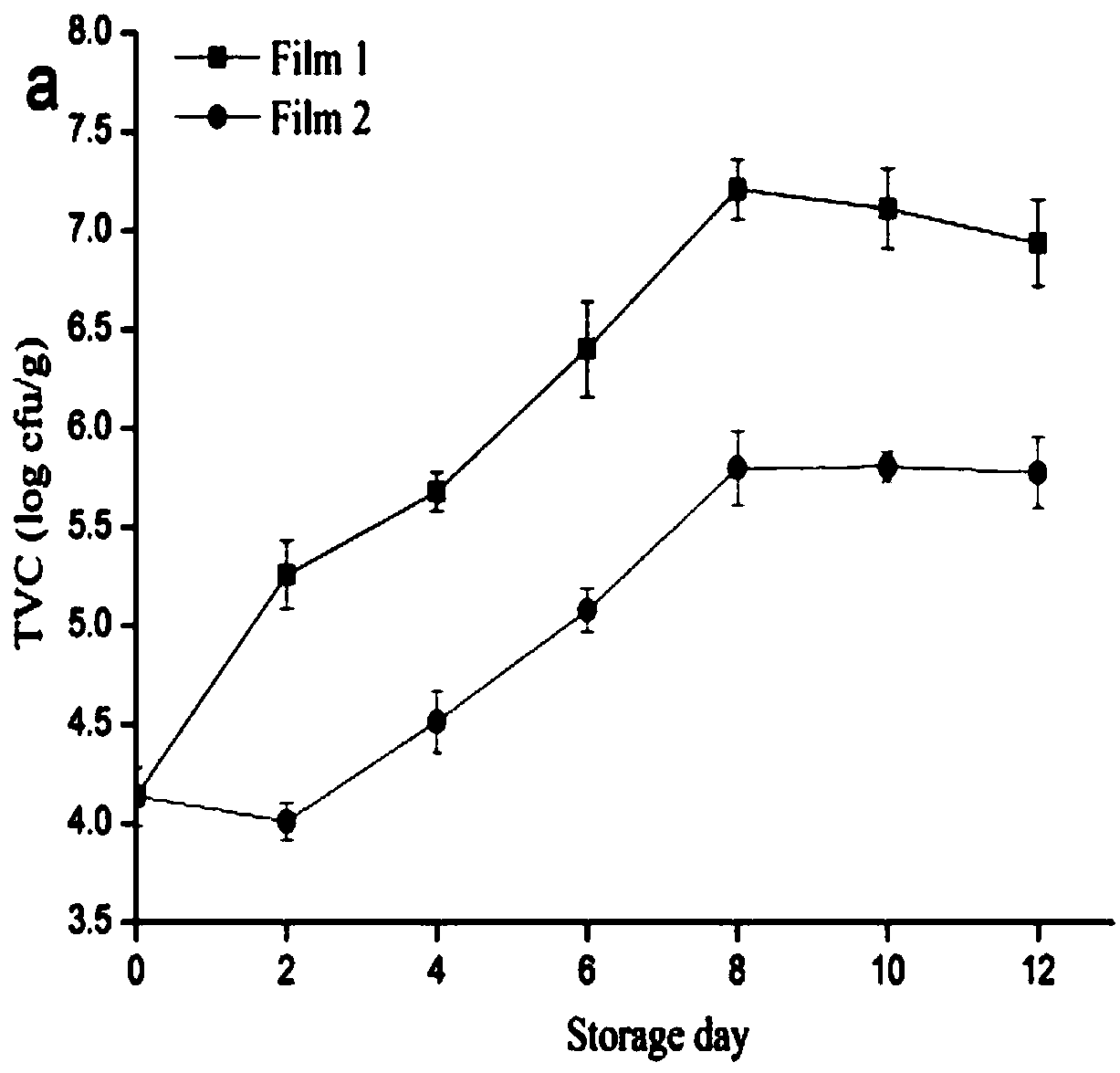

Active packaging film and preparation method thereof

InactiveCN107739462ASignificant antioxidant activityObvious antibacterial activityLow-density polyethyleneMaleic anhydride

The invention provides an active packaging film. The active packaging film comprises the following raw materials: low-density polyethylene, an ethylene-vinyl acetate copolymer, maleic anhydride and cinnamon essential oil, wherein the adding amount of the ethylene-vinyl acetate copolymer is 8 to 10 percent of the low-density polyethylene, the adding amount of the maleic anhydride is 2 to 5 percentof the low-density polyethylene and the adding amount of the cinnamon essential oil is 0.5 to 1.5 percent of the low-density polyethylene. In addition, the invention also provides a preparation methodof the active packaging film.

Owner:OCEAN UNIV OF CHINA

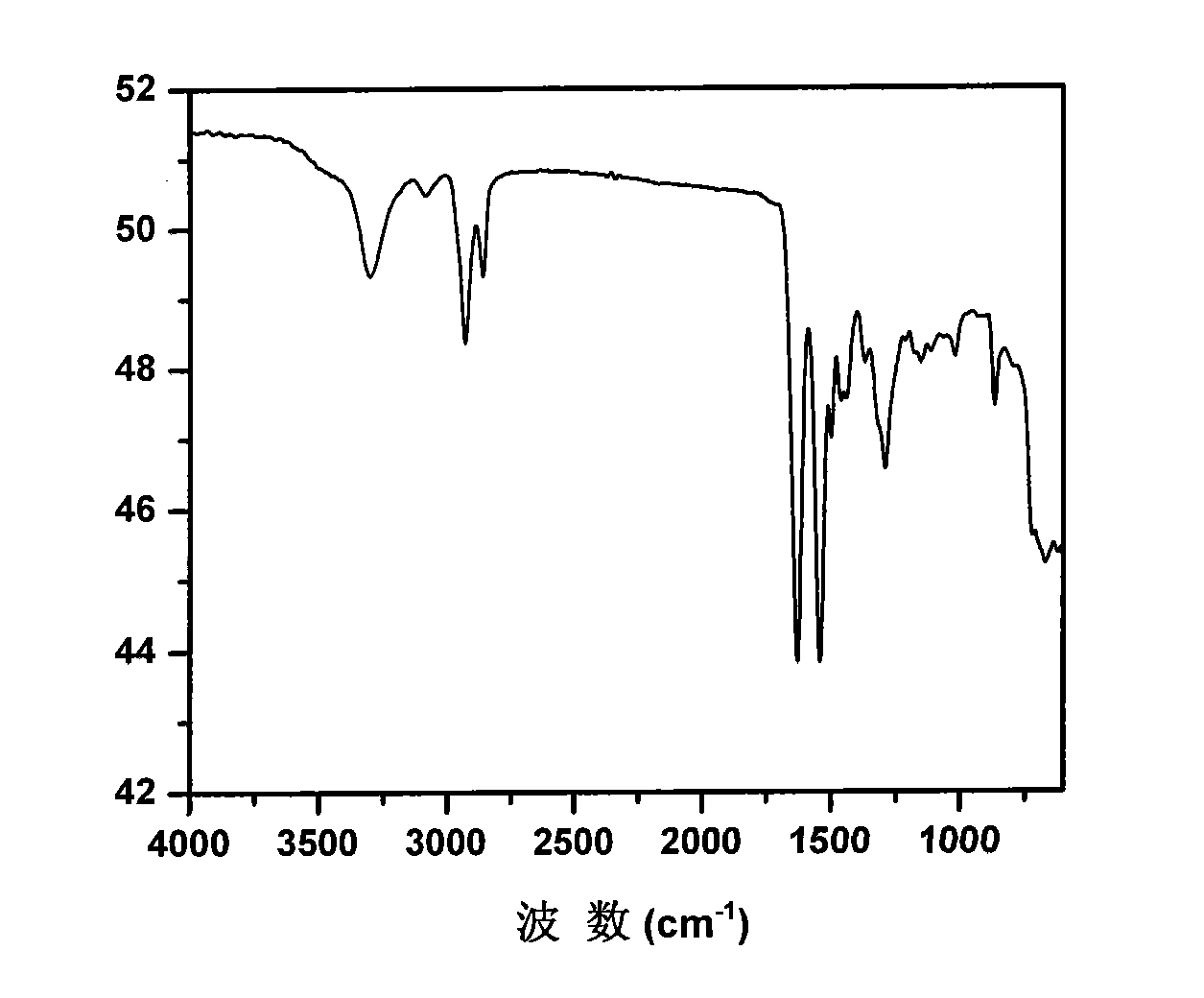

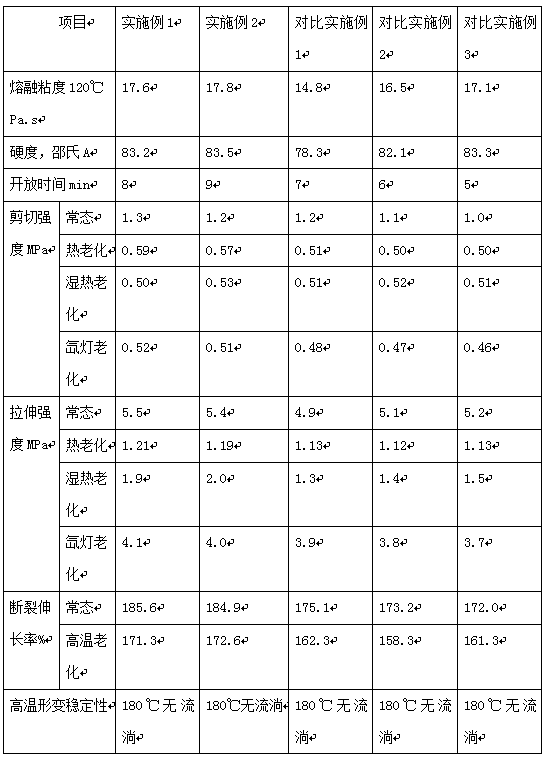

Preparation method of environment-friendly thermoplastic elastomer hot melt adhesive

InactiveCN111334239AEasy to useReduce energy consumptionPolyureas/polyurethane adhesivesElastomerThermoplastic elastomer

The invention, which belongs to the technical field of adhesives, relates to a preparation method of an environment-friendly thermoplastic elastomer hot melt adhesive. According to the preparation method of an environment-friendly thermoplastic elastomer hot melt adhesive, the prepared environment-friendly thermoplastic elastomer hot melt adhesive has no bubbles; no edge warping exists; the high aging resistance, temperature resistant, and corrosion resistant are realized; meanwhile, the adhesive is used in the form of solid powder, no volatile matter is discharged in the coating and bonding processes, renewable green and environment-friendly raw materials are used, environmental pollution is completely avoided; the powdery adhesive is used, and the adhesive has the advantages of being stable in performance, free of environmental pollution and the like, and is simple and convenient in preparation method, low in equipment requirement, low in cost and good in dispersion effect.

Owner:含山县金中环装饰材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com