Method of producing three-in-one electrode of solid oxide fuel battery

A solid oxide and fuel cell technology, which is applied in the field of surface engineering, can solve problems such as difficult to achieve uniform heating of particles, phase structure transformation, and difficulty in feeding into the center of the flame flow, so as to shorten the preparation cycle, improve ion conductivity, and improve operating performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

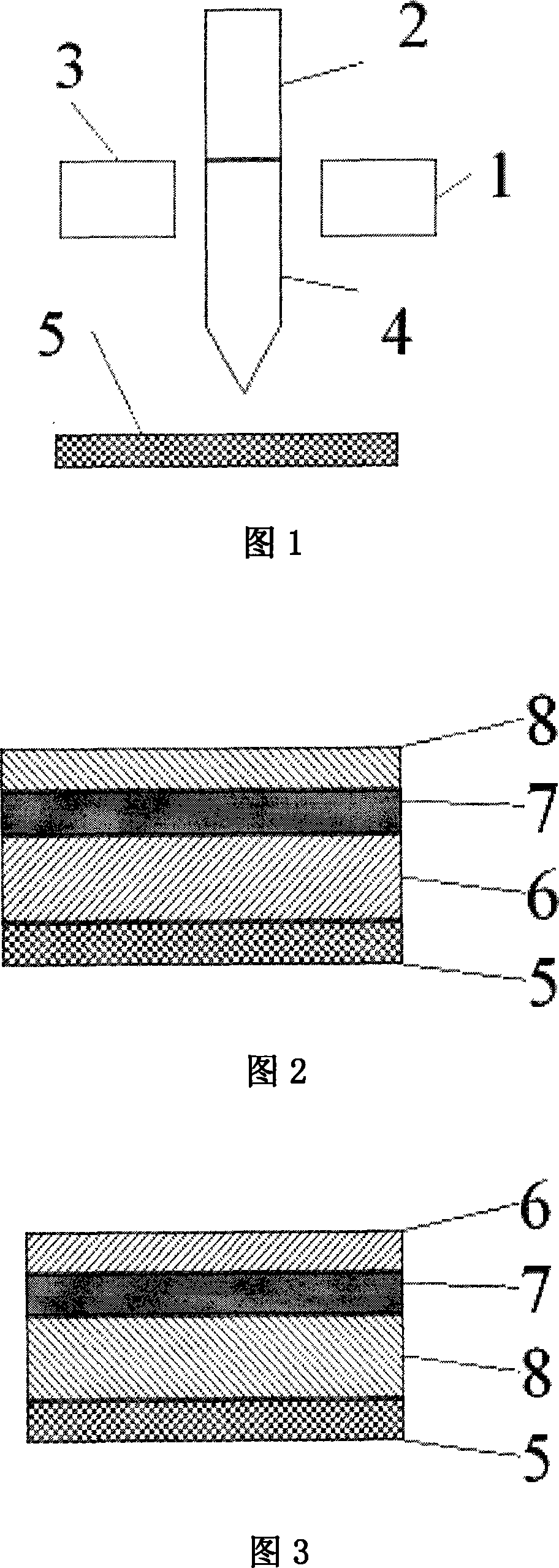

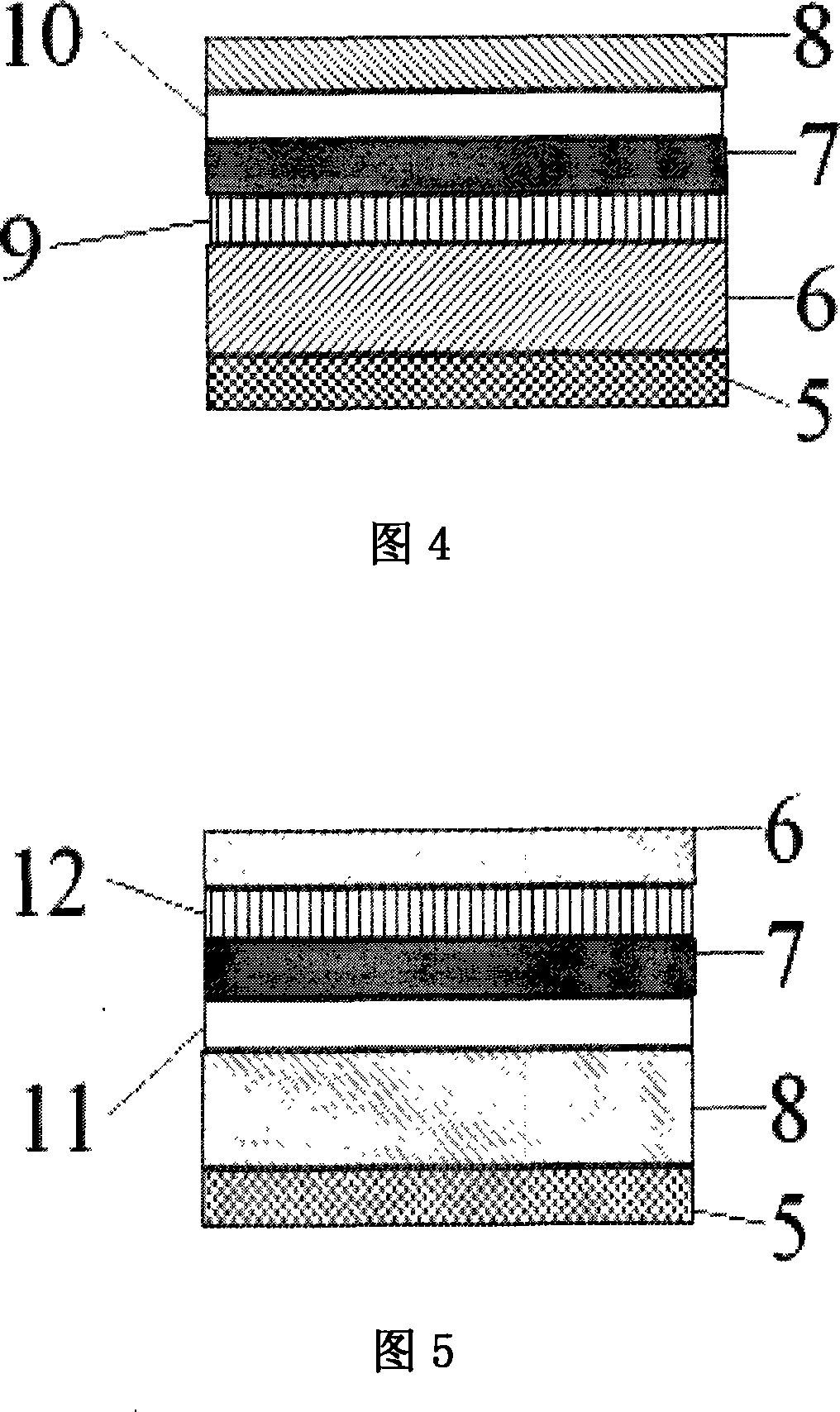

[0027] Embodiment 1: As shown in Figure 2, anhydrous ethanol, 8YSZ powder material, polyethylene glycol and polyvinyl alcohol are prepared into an electrolyte suspension, wherein the 8YSZ powder material accounts for 5% by mass of the suspension, and the dispersant polyethylene The glycol accounts for 0.5% by volume of the suspension, and the binder polyvinyl alcohol accounts for 1% by volume of the suspension. First use NiO+8YSZ anode material (NiO volume percentage is 35%, 8YSZ volume percentage is 65%), use the method of atmospheric plasma spraying, form anode 6 by spraying on substrate 5, thickness is 550 μ m, substrate 5 is porous ceramics; Send the configured 8YSZ suspension into the plasma jet 4 with the liquid material delivery system 1, and continue spraying on the anode 6 that has been sprayed and formed by using the liquid material plasma spraying method to prepare a dense electrolyte layer 7 with a thickness of 25 μm; finally use the cathode The material, lanthanum...

Embodiment 2

[0028] Embodiment 2: As shown in Figure 3, anhydrous ethanol, 8YSZ powder material, phosphoglyceride and polyvinyl alcohol are prepared into an electrolyte suspension, wherein the 8YSZ powder material accounts for 10% of the mass percentage of the suspension, and the dispersant phosphate glyceride The volume percentage of the suspension is 0.5%, and the binder polyvinyl alcohol is 1% of the volume of the suspension. Using the method of atmospheric plasma spraying, first adopt the cathode material La 1-x Sr x Co 1-y Fe y O 3 , x=0.1, y=1.0, spraying on the substrate 5 to form the cathode 8, the thickness is 700 μm, the substrate 5 is dense stainless steel; secondly, the configured 8YSZ suspension is sent into the plasma jet 4 with the liquid material delivery system 1, and the The liquid material plasma spraying method continues to spray on the negative electrode 8 that has been sprayed and formed to prepare a dense electrolyte layer 7 with a thickness of 35 μm; finally, Ni...

Embodiment 3

[0029] Embodiment 3: As shown in Figure 2, anhydrous ethanol, 8YSZ powder material, polyethylene glycol and glycerin are formulated into electrolyte suspension, wherein 8YSZ powder material accounts for 7.5% by mass percentage of the suspension, and the dispersant polyethylene glycol It accounts for 2.5% by volume of the suspension, and the binder glycerin accounts for 5% by volume of the suspension. First use NiO+8YSZ anode material (NiO volume percentage is 40%, 8YSZ volume percentage is 60%), use the method of atmospheric plasma spraying, form anode 6 by spraying on substrate 5, thickness is 600 μ m, substrate 5 is nickel foam; Next Send the configured 8YSZ suspension into the plasma jet 4 with the liquid material delivery system 1, and continue spraying on the anode 6 that has been sprayed and formed by using the liquid material plasma spraying method to prepare a dense electrolyte layer 7 with a thickness of 30 μm; finally use the cathode Material La 1-x Sr x Co 1-y Fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com