Abrasion-resistant LED heat dissipation lamp holder and preparation method thereof

A technology for a heat-dissipating lamp holder and a dispersant is applied in the field of wear-resistant LED heat-dissipating lamp holder and its preparation, which can solve the problems of limiting the application space of high-power LED lamps, shortening the service life of LED lamps, and poor moisture resistance and corrosion resistance. , to achieve the effect of improving mechanical strength and wear resistance, improving aging performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

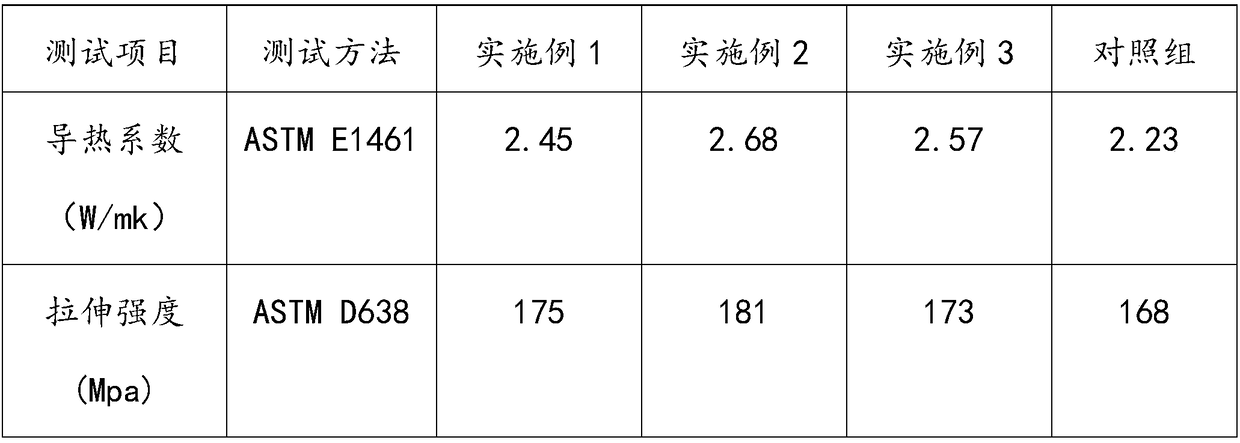

Examples

Embodiment 1

[0023] A wear-resistant LED heat-dissipating lamp holder, the raw materials of which are composed of 60 parts of polyamide resin, 40 parts of polypropylene resin, 1 part of methyl methacrylate-butadiene-styrene copolymer, 4 parts of polymethyl methacrylate, 15 parts of asbestos fiber, 3 parts of high alumina bauxite, 0.4 part of antioxidant 168, 0.3 part of oxidized polyethylene wax 316A, 0.2 part of ammonium polyacrylate.

[0024] A method for preparing a wear-resistant LED heat dissipation lamp holder, comprising the following steps:

[0025] (1) Weigh the above-mentioned raw materials in parts by weight, add polyamide resin, polypropylene resin, asbestos fiber and high-alumina bauxite to a high-speed mixer, mix and stir at 900r / min and heat up to 75°C, then add methyl Methyl acrylate-butadiene-styrene copolymer, polymethyl methacrylate, antioxidant 168, oxidized polyethylene wax 316A and ammonium polyacrylate were continuously stirred and mixed and heated to 100°C for a sec...

Embodiment 2

[0030] A wear-resistant LED heat-dissipating lamp holder, its raw materials are composed of: 75 parts of polyamide resin, 50 parts of polypropylene resin, 2 parts of methyl methacrylate-butadiene-styrene copolymer, 5 parts of polymethyl methacrylate, 17 parts of asbestos fiber, 5 parts of high alumina bauxite, 0.6 part of antioxidant 168, 0.5 part of oxidized polyethylene wax 316A, 0.3 part of ammonium polyacrylate.

[0031] A method for preparing a wear-resistant LED heat dissipation lamp holder, comprising the following steps:

[0032] (1) Weigh the above-mentioned raw materials in parts by weight, add polyamide resin, polypropylene resin, asbestos fiber and high alumina bauxite to a high-speed mixer, mix and stir at 1000r / min and heat up to 80°C, then add methyl Methyl acrylate-butadiene-styrene copolymer, polymethyl methacrylate, antioxidant 168, oxidized polyethylene wax 316A, and ammonium polyacrylate were continuously stirred and mixed for a second time and heated to 11...

Embodiment 3

[0037] A wear-resistant LED heat-dissipating lamp holder, the raw materials of which are composed of 90 parts of polyamide resin, 60 parts of polypropylene resin, 3 parts of methyl methacrylate-butadiene-styrene copolymer, 6 parts of polymethyl methacrylate, 20 parts of asbestos fiber, 6 parts of high alumina bauxite, 0.7 part of antioxidant 168, 0.8 part of oxidized polyethylene wax 316A, 0.5 part of ammonium polyacrylate.

[0038] A method for preparing a wear-resistant LED heat dissipation lamp holder, comprising the following steps:

[0039] (1) Weigh the above-mentioned raw materials in parts by weight, add polyamide resin, polypropylene resin, asbestos fiber and high alumina bauxite to a high-speed mixer, mix and stir at 1100r / min and heat up to 85°C, then add methyl Methyl acrylate-butadiene-styrene copolymer, polymethyl methacrylate, antioxidant 168, oxidized polyethylene wax 316A and ammonium polyacrylate were continuously stirred and mixed for a second time and heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com