High-temperature-resistant polylactic acid melt-blow electret non-woven filter material and preparation method and application thereof

A filter material, polylactic acid technology, applied in non-woven fabrics, separation methods, filtration and separation, etc., can solve problems such as affecting performance, cumbersome process, complicated process, etc., to improve filtration efficiency, simplify production process, and achieve good size The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

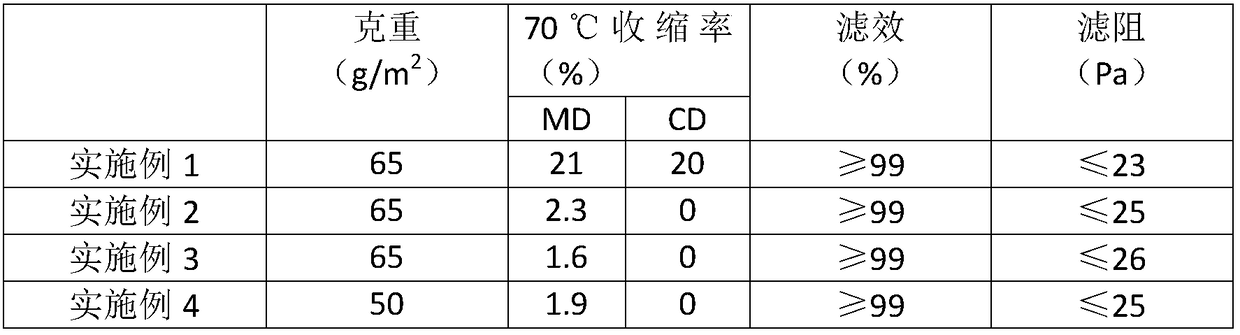

Embodiment 1

[0032] The production of the embodiment of the present invention mainly includes the following steps:

[0033] (1) Place the polylactic acid chips in the air at a temperature of 80°C for 12 hours.

[0034] (2) Place the polylactic acid slices dried in step (1) in the feeding hopper of the screw and cover and seal to isolate the outside air. The screw temperature is set as follows: the temperature of the first zone is 230°C, the temperature of the second zone is 235°C, the temperature of the third zone is 235°C, the temperature of the fourth zone is 235°C, the filter temperature is 235°C, the metering pump temperature is 240°C, The head temperature is 240°C, the hot air temperature is 260°C, the hot air pressure is 0.095MPa, the receiving distance is 10.5cm, and the spinning pressure is 0.92MPa. The rotating speed of the metering pump is 3 rpm, the web-laying speed is 5.74 Hz, the product width is 30 cm, and the average fiber diameter is 6 μm.

[0035] (3) The meltblown nonwoven fab...

Embodiment 2

[0038] The production of the embodiment of the present invention mainly includes the following steps:

[0039] (1) Place the polylactic acid chips in the air at a temperature of 80°C for 12 hours.

[0040] (2) Place the polylactic acid slices dried in step (1) in the feeding hopper of the screw and cover and seal to isolate the outside air. The screw temperature is set as follows: the temperature of the first zone is 230°C, the temperature of the second zone is 235°C, the temperature of the third zone is 235°C, the temperature of the fourth zone is 235°C, the filter temperature is 235°C, the metering pump temperature is 240°C, The head temperature is 240°C, the hot air temperature is 260°C, the hot air pressure is 0.095MPa, the receiving distance is 10.5cm, the spinning pressure is 0.92MPa, the metering pump speed is 3rpm, the web speed is 5.74Hz, the product width It is 30cm and the average fiber diameter is 6μm.

[0041] (3) Send the meltblown nonwoven fabric prepared in step (2)...

Embodiment 3

[0045] (1) Place the polylactic acid chips in the air at a temperature of 80°C for 12 hours.

[0046] (2) Place the polylactic acid slices dried in step (1) in the feeding hopper of the screw and cover and seal to isolate the outside air. The screw temperature is set as follows: the temperature of the first zone is 230℃, the temperature of the second zone is 235℃, the temperature of the third zone is 235℃, the temperature of the fourth zone is 235℃, the filter temperature is 235℃, the metering pump temperature is 240℃, The head temperature is 240°C, the hot air temperature is 260°C, the hot air pressure is 0.095MPa, the spinning distance is 10.5cm, the spinning pressure is 0.92MPa, the metering pump speed is 3rpm, and the web speed is 5.74Hz. The width is 30 cm, and the average fiber diameter is 6 μm.

[0047] (3) The meltblown nonwoven fabric prepared in step (2) is fed into a heat setting device. The surface temperature of the heating roller of the heat setting device is 130°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com