Preparation method of environment-friendly thermoplastic elastomer hot melt adhesive

A technology of thermoplastic elastomers and hot melt adhesives, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of affecting performance and poor effect, and achieve low solvent resistance and low energy consumption. Production cost, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

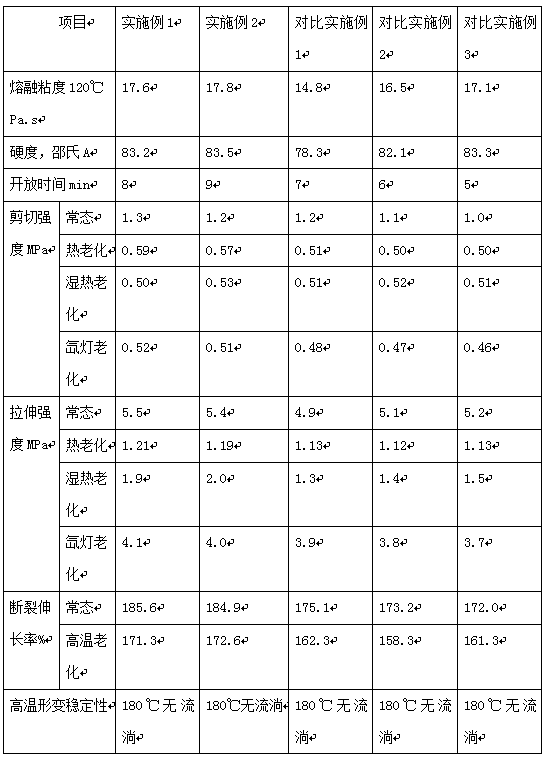

Examples

Embodiment 1

[0021] (1) Preparation of rice bran oil methyl ester: In a reaction kettle equipped with an electric stirrer, a reflux condenser and a thermometer, add 47 parts of rice bran oil that has been pre-dehydrated to a water content of 0.1% and heated to 35°C in a constant temperature water bath , add 53 parts of methanol solution containing 5% mass fraction of sodium hydroxide, stir and react for 2 hours, add 5% mass fraction of hydrochloric acid to neutralize to pH 4, pour the reaction solution into a separatory funnel, and let it stand for stratification. Remove the lower liquid, wash the upper liquid with deionized water 3 times until neutral, and distill off the water under reduced pressure to obtain clear and transparent rice bran oil methyl ester; (2) Synthesis of rice bran oleic acid-based polyester polyol: Add 61 parts of rice bran oil methyl ester, 41 parts of adipic acid, and 35 parts of ethylene glycol prepared in step (1) to the reaction kettle of the reactor, thermometer...

Embodiment 2

[0024] (1) Preparation of rice bran oil methyl ester: In a reaction kettle equipped with an electric stirrer, a reflux condenser and a thermometer, add 47 parts of rice bran oil that has been pre-dehydrated to a water content of 0.1% and heated to 35°C in a constant temperature water bath , add 51 parts of methanol solution containing 5% sodium hydroxide by mass fraction, stir and react for 1 h, add hydrochloric acid with 5% mass fraction to neutralize to pH 4, pour the reaction solution into a separatory funnel, and let it stand for stratification. Remove the lower layer liquid, wash the upper layer liquid with deionized water for 3 times until neutral, and distill off the water under reduced pressure to obtain clear and transparent rice bran oil methyl ester;

[0025] (2) Synthesis of rice bran oleic acid-based polyester polyol: 55 parts of rice bran oil methyl ester prepared in step (1), Add 33 parts of adipic acid and 35 parts of ethylene glycol into it, blow nitrogen for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com