Active packaging film and preparation method thereof

A packaging film and active technology, which is applied in the field of active packaging film and its preparation, can solve the problems of difficult application and achieve the effect of maintaining effect, easy production and extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, the preparation method and formula of active packaging film

[0040] The formula of this embodiment is: low density polyethylene 1000g, ethylene-vinyl acetate copolymer 100g, maleic anhydride 30g, cinnamon essential oil 10g.

[0041] Preparation method: comprising the following steps:

[0042] Mix ethylene-vinyl acetate copolymer (EVA) and maleic acid (OREVAC) evenly, add cinnamon essential oil and continue to mix evenly, continue to add LDPE resin to mix, the mixed masterbatch is blown with a film blowing machine, the temperature of the film blowing machine The setting is: 200°C in the membrane body area; 175°C in the split flow area, and the thickness of the produced film is 66.2 μm. It generally takes 20-30 minutes from feeding to film discharge.

Embodiment 2

[0043] Embodiment 2, the preparation method and formula of active packaging film

[0044] The formula of this embodiment is: 1000 g of low density polyethylene, 80 g of ethylene-vinyl acetate copolymer, 40 g of maleic anhydride, and 15 g of cinnamon essential oil.

[0045] The preparation method of the active packaging film of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

[0046]The present invention selects extrusion film forming as a research direction to study novel active packaging. Low-density polyethylene (LDPE) and cinnamon essential oil were selected for extrusion blow molding, and ethylene-vinyl acetate (EVA) was selected as a solubilizer, and maleic anhydride (OREVAC) was used as a linker to produce cinnamon essential oil-LDPE active film.

Embodiment 3

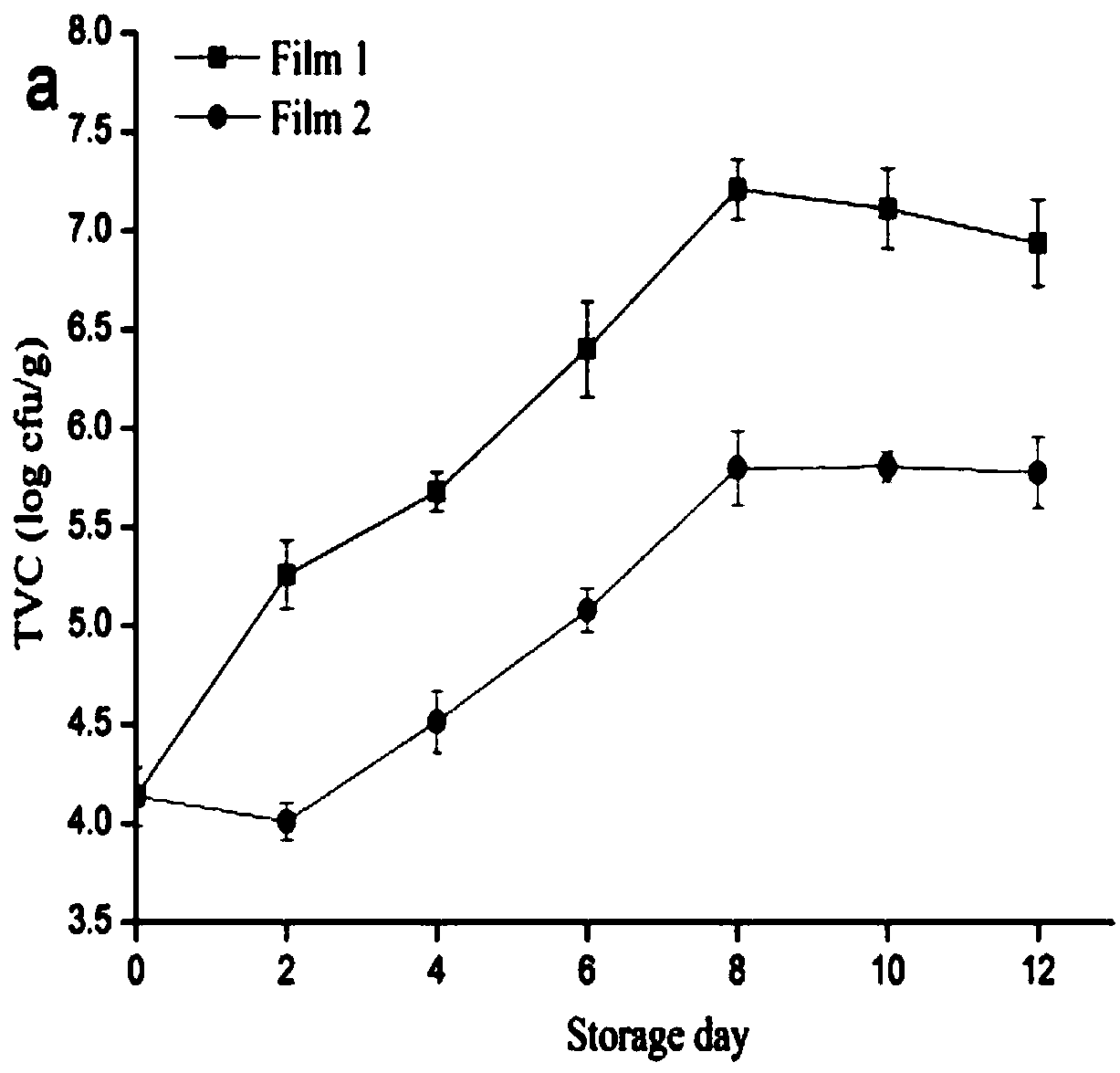

[0047] Embodiment 3, the physical property of cinnamon essential oil active film and the verification test of fresh-keeping effect

[0048] 1. Composite verification and physical properties of cinnamon essential oil-LDPE film

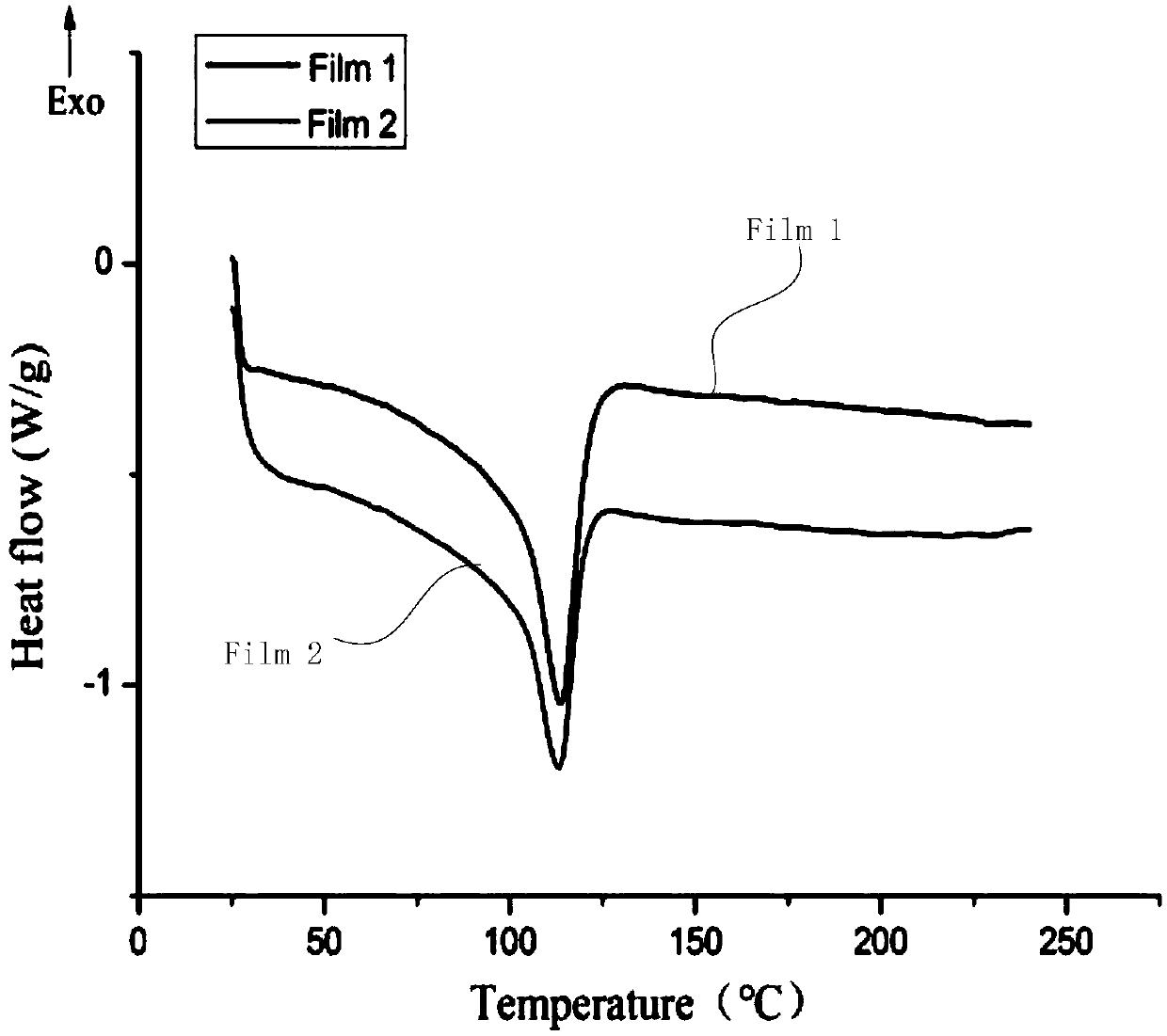

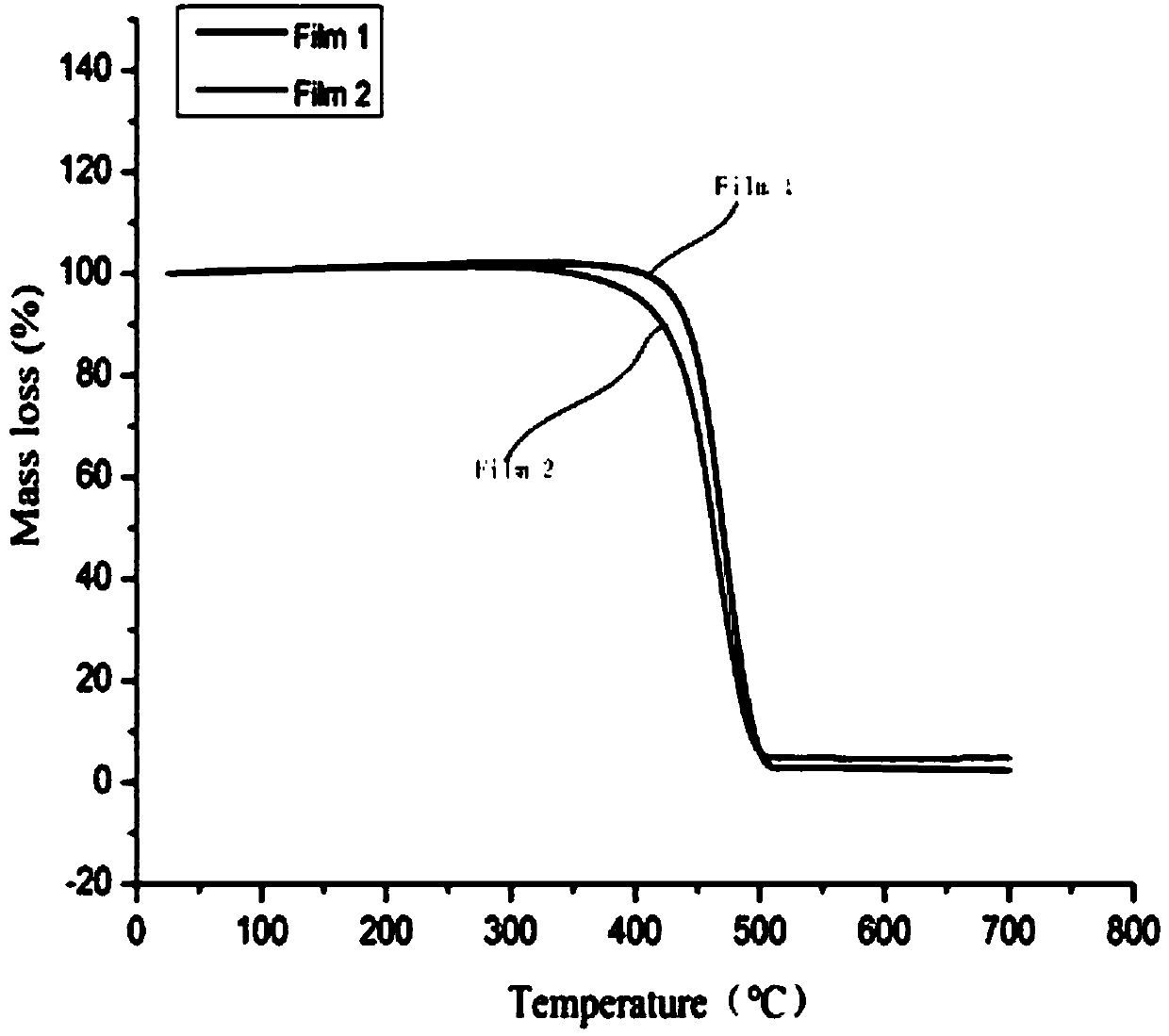

[0049] Since the present invention is the first time that cinnamon essential oil is compounded into LDPE, this study first verified the essential oil and LDPE by using characterization techniques such as scanning electron microscopy (SEM), thermogravimetry (TGA) and differential calorimetry (DSC). The composability of ethylene and its relatively stable thermodynamic properties after compounding. The test results are shown in the figure (Film 1, Film 2 represent pure film and active film respectively):

[0050] figure 1 The DSC curves show that, compared with the control film, the parameter values of the active film such as melting point have not changed, and the active film has a wider endothermic peak, which is due to the thermal migration of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com