Macadamia nut tea and preparation method thereof

A technology for nut tea and nuts, which is applied to the field of macadamia nut tea and its preparation, can solve the problems of single taste, poor stability, easy oxidation and rancidity of macadamia nut products, facilitate continuous production, and realize large-scale production and application. , good for digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

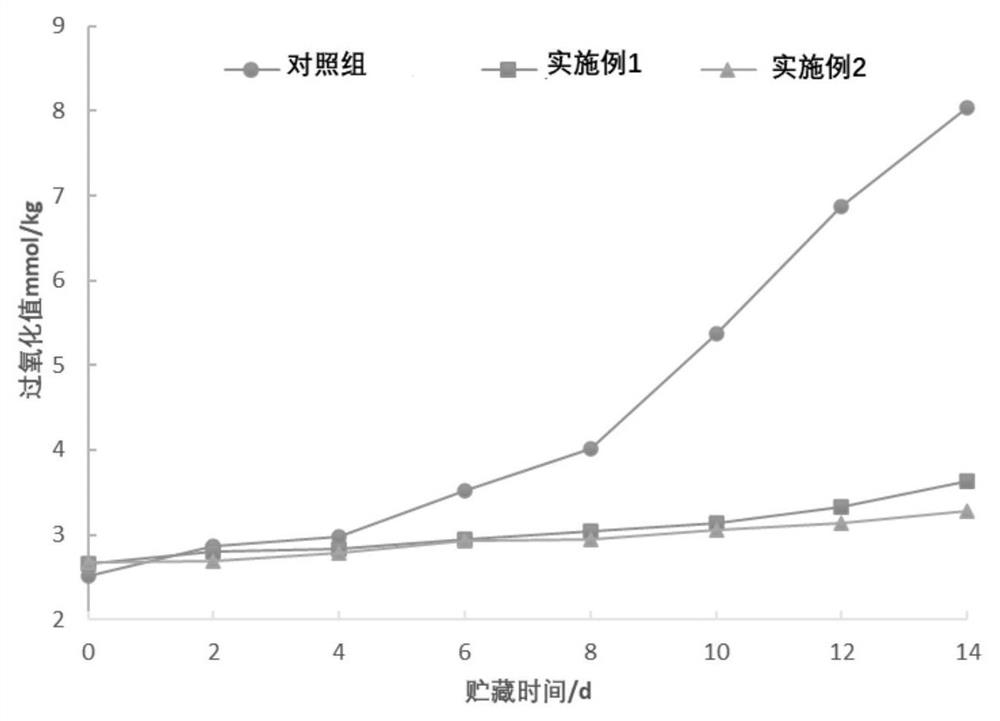

Embodiment 1

[0030] 1) Take 1.5 parts of black tea and soak in 750 parts of hot water at 90°C for 30 minutes, filter out the tea dregs, and the obtained extract is tea soup;

[0031] 2) After mixing 50 parts of maltodextrin, 50 parts of wall material sucrose, 0.3 part of mono-diglyceride fatty acid ester, 0.9 part of sucrose fatty acid ester and 2.25 parts of phospholipid, put it in the tea soup obtained in step 1), and then add Wash 100 parts of macadamia kernels, and then refine the above mixture with a colloid mill. If there are still small particles after the colloid mill, then return to colloid mill again until there are no small particles.

[0032] 3) Pump the material liquid after refining in step 2) into the stainless steel batching tank, heat to 60°C, use a high-pressure homogenizer to homogenize at 35Mpa, and then use an ultra-high pressure instantaneous sterilizer or a stainless steel constant temperature heating tank to sterilize The temperature is 90° C., and the sterilization...

Embodiment 2

[0036] 1) Take 3 parts of Pu'er tea and soak in 1000 parts of hot water at 90°C for 30 minutes, filter out the tea dregs, and the obtained extract is tea soup;

[0037] 2) After mixing 60 parts of maltodextrin, 40 parts of wall material sucrose, 0.5 part of mono- and diglyceride fatty acid ester, 0.7 part of sucrose fatty acid ester and 2 parts of phospholipid, put it in the tea soup obtained in step 1), and then add Wash 100 parts of macadamia kernels, and then refine the above mixture with a colloid mill. If there are still small particles after the colloid mill, then return to colloid mill again until there are no small particles.

[0038] 3) Pump the material liquid after refining in step 2) into the stainless steel batching tank, heat to 60°C, use a high-pressure homogenizer to homogenize at 35Mpa, and then use an ultra-high pressure instantaneous sterilizer or a stainless steel constant temperature heating tank to sterilize The temperature is 95° C., and the sterilization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com