Method for preparing high-temperature-resistant nylon by utilizing amidation reaction of polyester

A technology of amidation reaction and high temperature resistance, which is applied in the field of nylon preparation, can solve the problems of many residues on the wall of the kettle, high melt viscosity, side reactions, etc., so as to improve heat resistance, physical and mechanical properties, physical and mechanical properties. The effect of stable and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

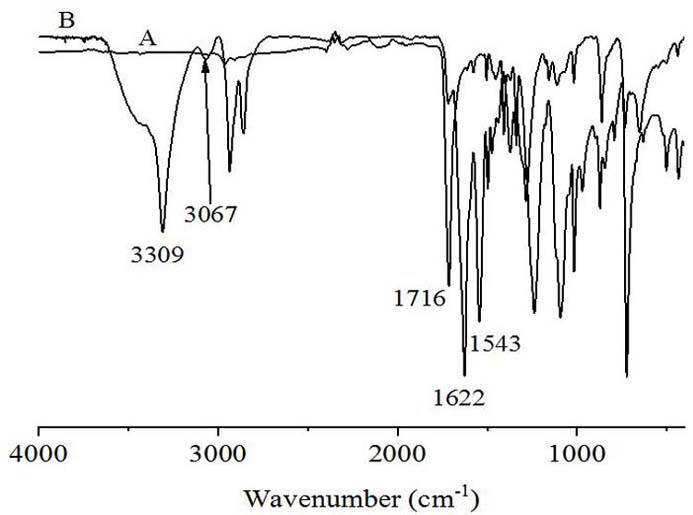

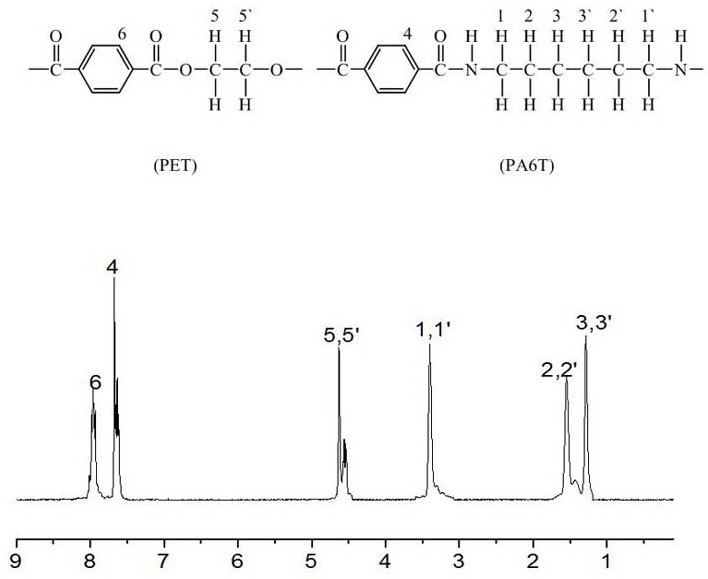

[0028] A kind of method utilizing the amidation reaction of polyester to prepare high temperature resistant nylon, comprises the following steps:

[0029] 1) Weigh 192g of polyethylene terephthalate (PET), 116g of hexamethylenediamine, 0.92g of sodium hypophosphite and 924g of sulfolane into an autoclave. Wherein, the mol ratio of hexamethylenediamine and PET is 1:1, the amount of sodium hypophosphite is 0.3% of the PET quality, and the mass ratio of the total mass of raw materials to the solvent is 1:3; 2 Replace the gas 3 times, turn on the stirring and heating device, when the temperature rises to 200°C, keep it warm for 1h, release the steam for 2h, vacuumize for 1h, turn off the heating, cool to room temperature, and take out the product;

[0030] 2) Add 924g of acetone to the product for washing and suction filtration, and repeat the operation 3 times; put the product in a vacuum drying oven and dry it at 60°C for 24 hours to finally obtain white powdery high-temperature...

Embodiment 2

[0032] A kind of method utilizing the amidation reaction of polyester to prepare high temperature resistant nylon, comprises the following steps:

[0033] 1) Weigh 256g of polytrimethylene 2,6-naphthalate (PPN), 172g of decanediamine, 1.28g of phosphorous acid and 1284g of trichloroacetic acid into an autoclave. Wherein, the mol ratio of decyl diamine and PEN is 1:1, and the sodium hypophosphite consumption is 0.3% of the PPN quality, and the mass ratio position of raw material total mass and solvent is 1:3; 2 Replace the gas 3 times, turn on the stirring and heating device, when the temperature rises to 200°C, keep the temperature and pressure for 1 hour, release the steam for 2 hours, and vacuum for 1 hour; turn off the heating, cool to room temperature, and take out the product;

[0034] 2) Add 1284g of ethanol to the product for washing and suction filtration, and repeat the operation 3 times; put the product in a vacuum drying oven and dry it at 60°C for 24 hours to final...

Embodiment 3

[0036] A kind of method utilizing the amidation reaction of polyester to prepare high temperature resistant nylon, comprises the following steps:

[0037] 1) Weigh 226g of polybutylene 1,4-cyclohexanedicarboxylate (PBC), 200g of dodecyl diamine, 1.28g of H10 and 1278g of chlorophenol into an autoclave. Wherein, the mol ratio of decyl diamine and PEN is 1:1, and the sodium hypophosphite consumption is 0.3% of the PBC quality; 2 Replace the gas 3 times, turn on the stirring and heating device, when the temperature rises to 200°C, keep the temperature and pressure for 1 hour, release the steam for 2 hours, and vacuum for 1 hour; turn off the heating, cool to room temperature, and take out the product;

[0038]2) Add 1278g of methanol to the product for washing and suction filtration, and repeat the operation 3 times; put the product in a vacuum drying oven and dry it at 60°C for 24 hours to finally obtain white powdery high-temperature-resistant nylon PA12C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com