Bearing support

A technology for bearing supports and bearings, applied in the direction of bearing components, shafts, bearings, and rigid supports of bearing components, can solve problems such as poor sealing effect, achieve stable sealing performance, not easy to fail, and improve sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

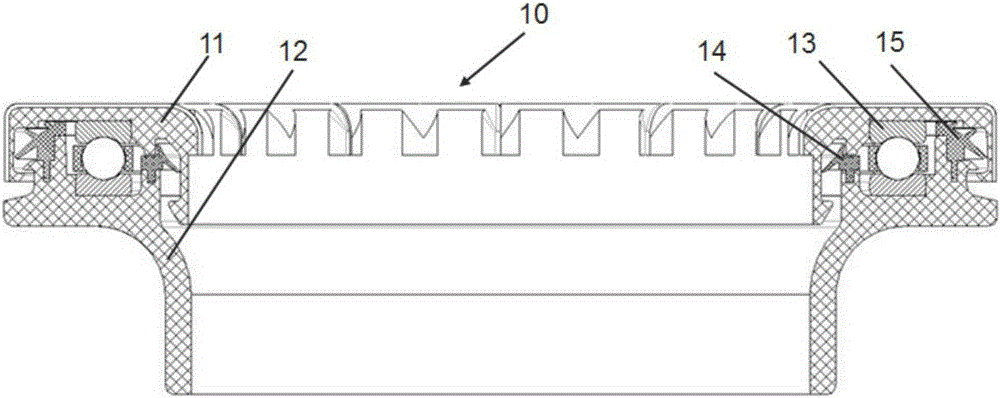

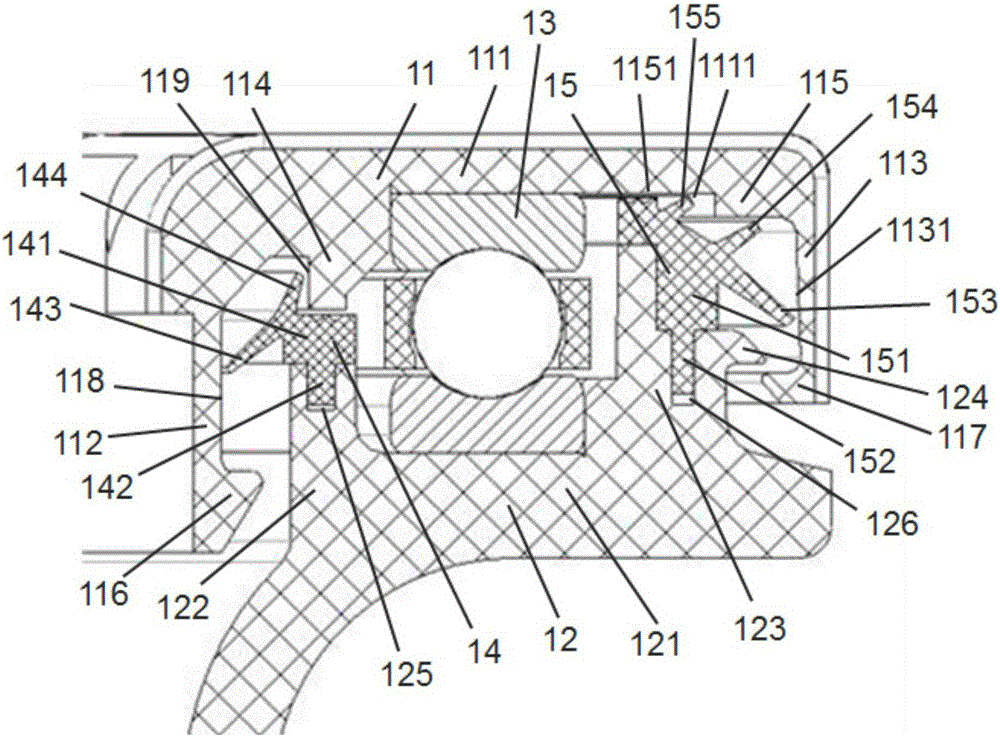

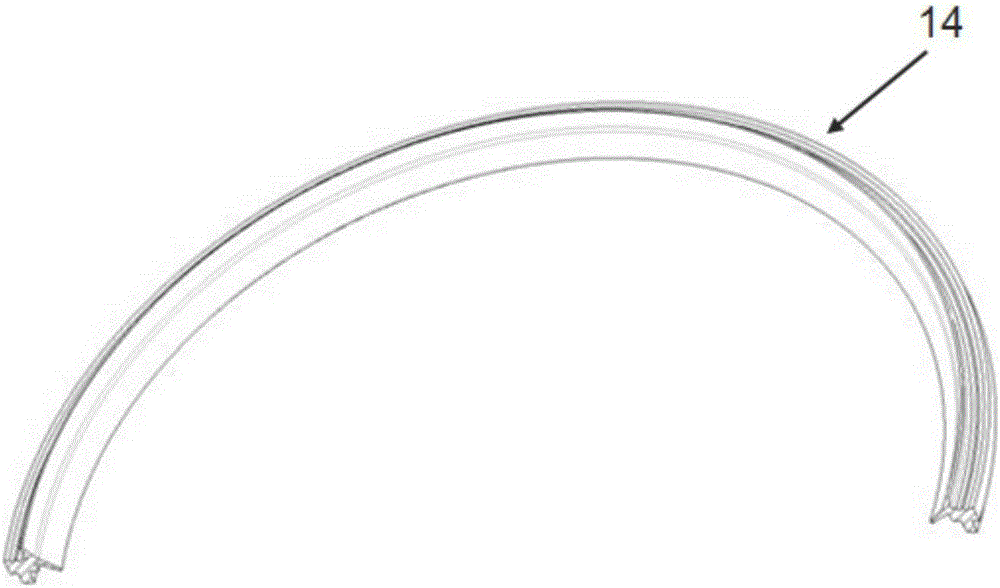

[0024] Embodiment 1 of bearing support 10 of the present application, such as figure 1 As shown, the bearing support 10 includes an upper housing 11 , a lower housing 12 , a bearing 13 accommodated between the upper housing 11 and the lower housing 12 , a radial seal 14 and an axial seal 15 .

[0025] Specifically, both the upper casing 11 and the lower casing 12 are generally in the shape of a ring disk, and the two can adopt the buckle structure as shown in the figure to realize interlocking, and form an accommodating chamber for the bearing 13, and the bearing 13 is placed in the Specifically, the application does not specifically limit the type of the bearing 13 in the accommodating cavity, and it can be flexibly configured according to specific application environments or requirements, such as deep groove ball bearings or angular contact bearings, which are shown in the figure as deep groove ball bearings.

[0026] In order to ensure the sealing of the bearing and prevent...

Embodiment 2

[0039] Embodiment 2 of the bearing support 20 of the present application has basically the same structure as the bearing support 10, such as Figure 5 As shown, the bearing support 20 includes an upper shell 21 , a lower shell 22 , a bearing 23 accommodated between the upper shell 21 and the lower shell 22 , a radial seal 24 and an axial seal 25 . Compared with the bearing support 10 in Embodiment 1, the bearing support 20 has the following differences:

[0040] The radial outer side of the lower convex ring 214 of the upper housing 21 forms a third side wall 2142, the surface of the third side wall 2142 forms a certain angle with the rotation axis of the bearing 23, and the radial seal 24 There is also a third sealing lip 245 protruding from the radial seal body 241. The second radial sealing lip 244 and the third sealing lip 245 are respectively located on both radial sides of the lower convex ring 214. The third sealing lip An axial seal is formed between 245 and the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com