Device for alternately switching part of evaporator into condenser to defrost in due time

An evaporator and condenser technology, applied in the field of defrosting equipment, can solve the problems of untimely startup and shutdown of defrosting functions, low defrosting efficiency, and short equipment life, so as to facilitate popularization and use, ensure continuous heating, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

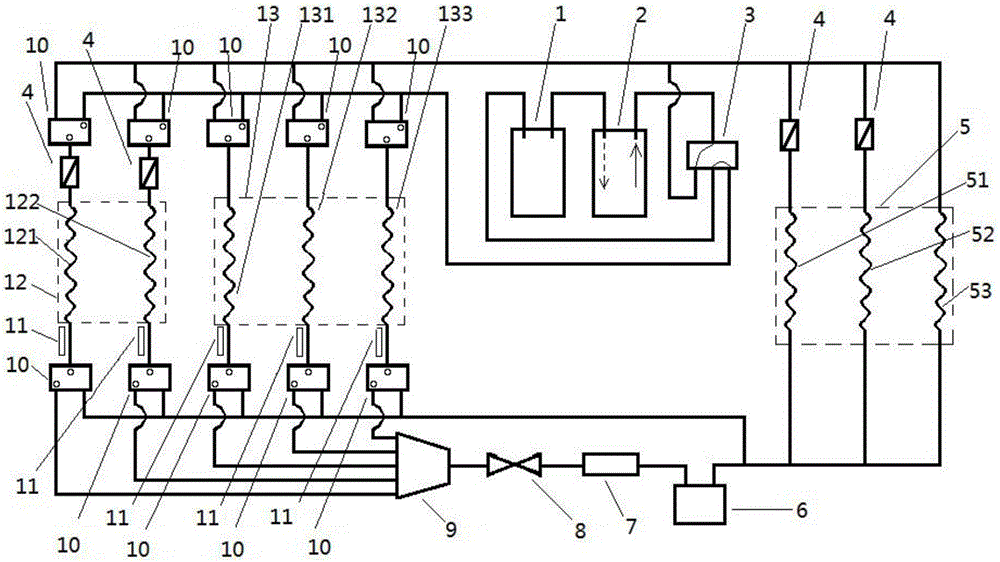

[0022] The present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0023] Such as figure 1 As shown, a device that alternately converts part of the evaporator into a condenser for defrosting in a timely manner includes a gas-liquid separator 1, a compressor 2, a four-way reversing valve 3, a solenoid valve 4, a first condenser 51, a second Condenser 52, third condenser 53, liquid receiver 6, filter 7, expansion valve 8, liquid separator 9, three-way steering valve 10, defrost sensor 11, first standby evaporator 121, second standby An evaporator 122 , a first primary evaporator 131 , a second primary evaporator 132 , and a third primary evaporator 133 .

[0024] Specifically, in the condenser 5, the first condenser 51, the second condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com