A small punch test device that can directly measure deflection

A testing device and small punch technology, applied in the field of reactor engineering, can solve problems such as uneven sample clamping force, and achieve the effect of direct sample deflection and direct in-situ measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

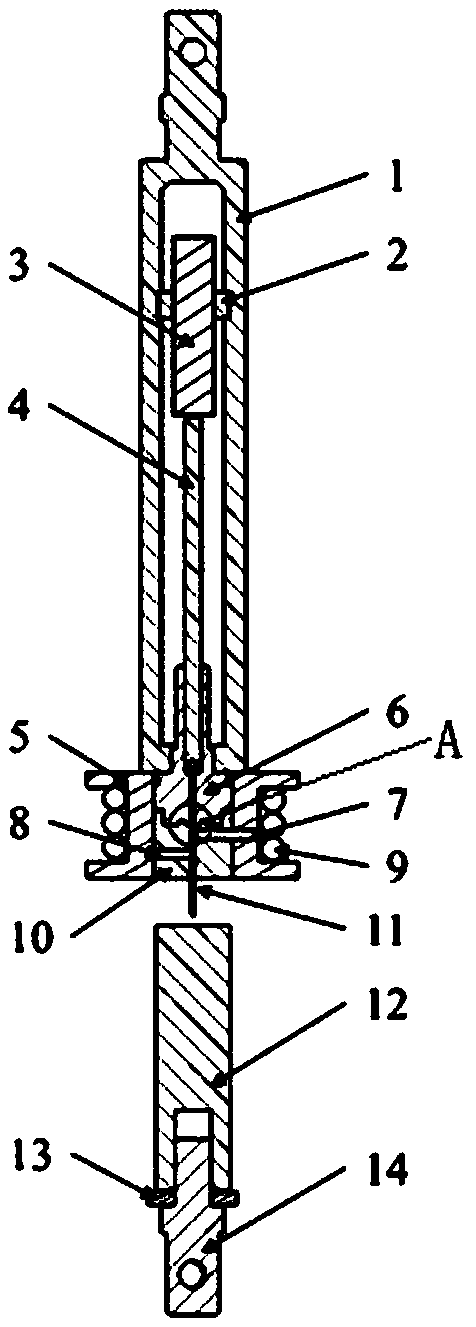

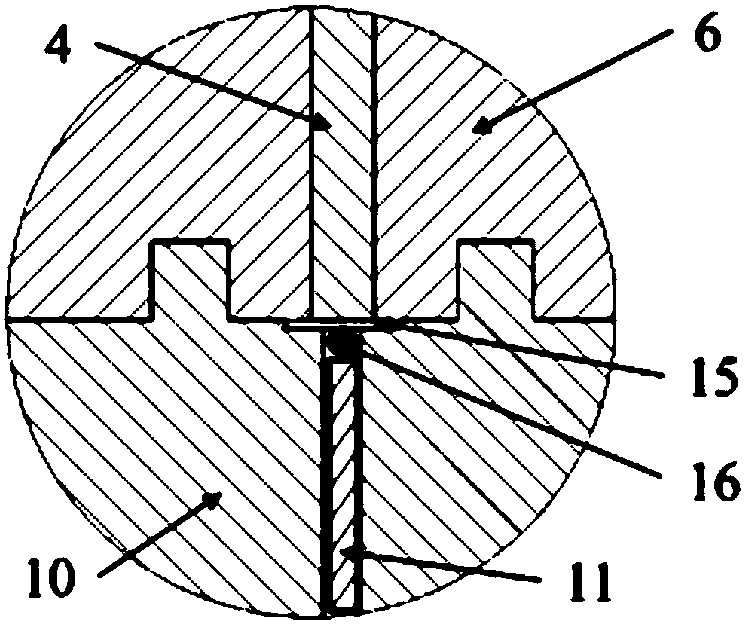

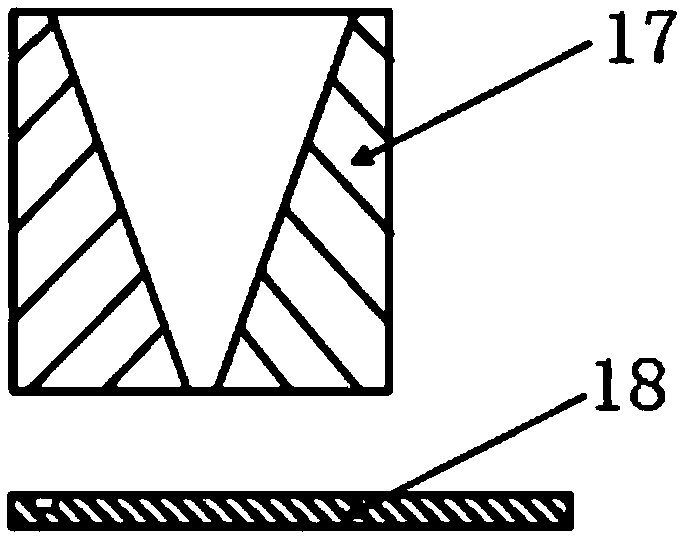

[0031] In this embodiment, the upper clamping die 6, the lower clamping die 10 and the punch 11 are cylindrical. Before the test, the irradiated reactor pressure vessel steel was made into a thin disc-shaped small sample of φ3×0.3mm. Adjust the height of the punch 11 to a suitable position, tighten the first jacking wire located in the first jacking wire socket 8 to fix the punch 11, place the ball funnel 17 on the upper surface of the lower clamping die 10, and use the ball scoop 18 Take out the stamping ball 16 and put it into the ball funnel 17, the stamping ball 16 can fall into the center through hole of the lower clamping die 10 and be located at the upper end of the punch 11; then put the sample into the circular sample groove 15 of the lower clamping die 10 In the process, tighten the lower clamping die 10 and the upper clamping die 6, loosen the first jacking wire in the first jacking wire socket 8, make the punch 11 drop freely onto the rotating seat 12, and connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com