Micro blind area focusing ultrasonic probe for manually detecting composite material component

A composite material component, manual detection technology, applied in the direction of analyzing materials, using sonic/ultrasonic/infrasonic waves for material analysis, measuring devices, etc., can solve the problems of increasing the blind area of composite material surface detection, reducing the reliability and efficiency of detection results, etc. Achieve the effect of reducing detection blind spots, improving reliability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

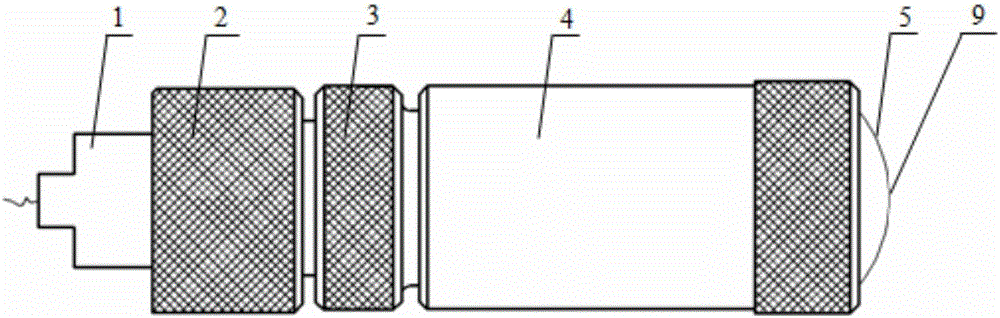

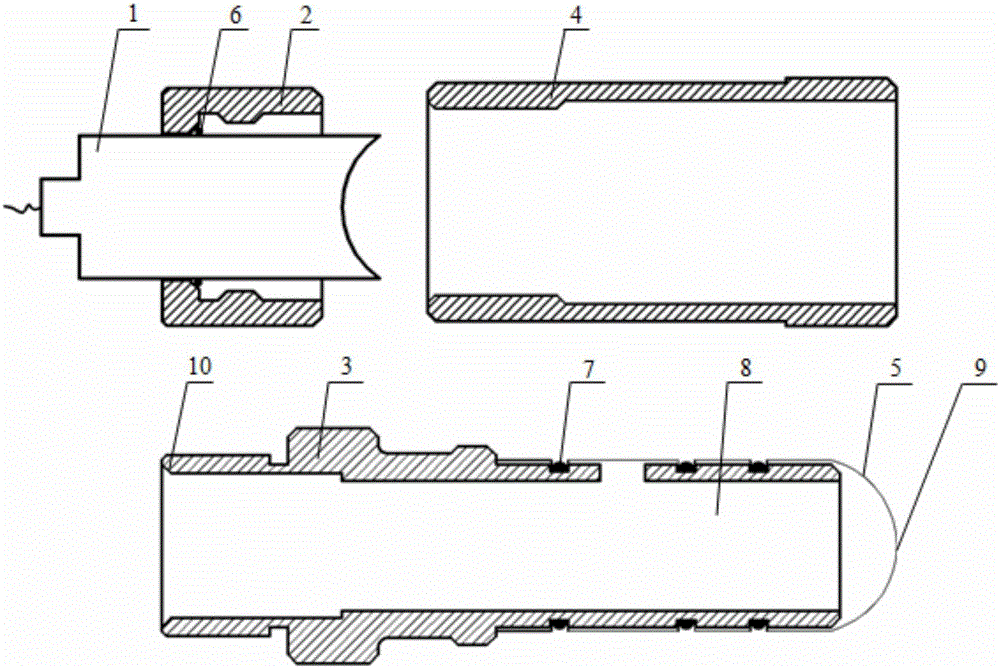

[0013] See attached figure 1 , figure 2 As shown, this kind of micro-blind spot focused ultrasonic probe for manually detecting composite material components is characterized in that: the probe includes an ultrasonic transducer 1 and a sealing cover 2 set on the ultrasonic transducer 1, and one end of the sealing cover 2 is connected to the The outer surface of the ultrasonic transducer 1 is in contact with a sealing ring 6 for sealing. The inner surface of the other end of the sealing cover 2 is processed with internal threads, and the left end of the couplant cavity housing 3 is inserted Installed between the open end of the sealing cover 2 and the outer surface of the ultrasonic transducer 1, the external thread on the left end of the couplant cavity housing 3 is connected with the internal thread on the open end of the sealing cover 2, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com