Chip temperature testing device and testing method

A chip and equipment technology, applied in the equipment and testing field for chip temperature testing, can solve the problem of high cost of use, and achieve the effects of low cost, reasonable design, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

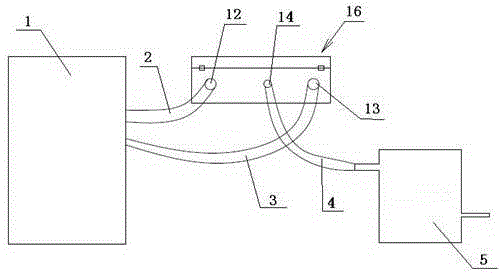

[0019] First, introduce the specific structure of the present invention. The present invention includes a high and low temperature main engine 1, a high and low temperature box body 16 communicated with the high and low temperature main engine 1 through the inlet pipe 2 and the return air pipe 3, and a high and low temperature box body connected to the high and low temperature box body through the drying air pipe 4. 16 connected drying towers 5.

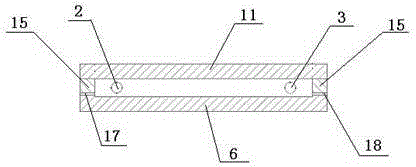

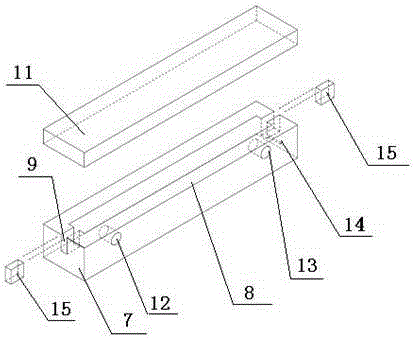

[0020] Wherein, the high and low temperature box 16 includes a base plate 6, and the base plate 6 is provided with a test track for passing the integrated circuit chip and a test assembly connected with the test track; the four sides of the base plate 6 are provided with side plates perpendicular to the base plate 6, That is, two short side plates 7 and two long side plates 8, wherein the two short side plates 7 are provided with grooves 9, the bottom of the groove 9 is buried with a heating rod, and the bottom plate 6 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com