Wood floor complete-set color mixing and matching system based on Internet of things

A wood floor and IoT technology, applied in the field of intelligent color matching system, can solve the problems of long paint color matching time, low color matching accuracy, paint waste, etc., to achieve real-time rapid color matching, shorten color matching time, and improve color matching. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and examples, but not as a basis for limiting the present invention.

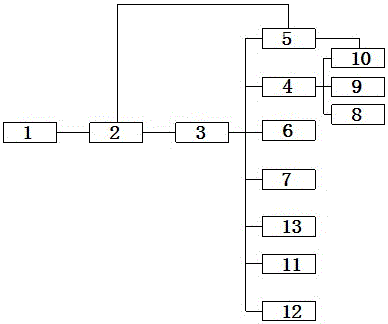

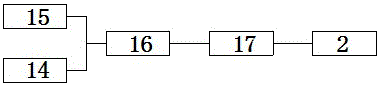

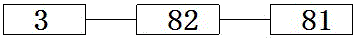

[0022] Example. A complete color matching system for wooden floors based on the Internet of Things, which consists of Figure 1 to Figure 6 As shown, it includes the wooden floor color measurement system 1, the wooden floor color measurement system 1 is connected to the wooden floor color matching database system 2, the wooden floor color matching database system 2 is connected to the paint matching processor 3, and the paint matching processor 3 is connected to the color matching generator System 4, color matching and finishing subsystem 5, Internet of Things system 6 and user management system 7, and color matching and finishing subsystem 5 is connected with wooden floor color matching database system 2; described color matching generation subsystem 4 includes paint generation subsystem 8, image disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com