Apparatus and method improving tobacco leaf yield after first time threshing

A technology for large pieces and blades, which is applied in the field of devices that increase the rate of sheet production after a dozen, can solve the problems of increasing blade loss, increasing blade fragmentation, and difficulty in making further improvements, so as to reduce the rate of large sheets and improve the The effect of improving the film output rate and improving the medium film rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

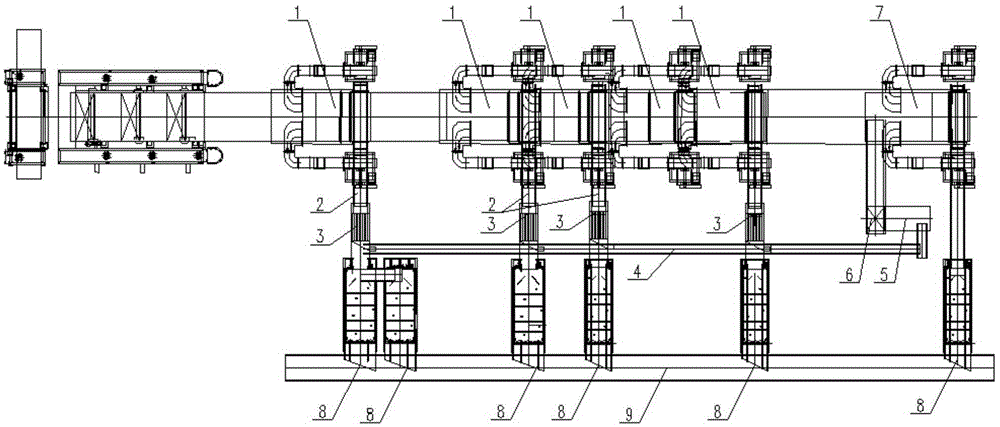

[0018] like figure 1 Shown, a kind of device that improves the output rate after a dozen, comprises air separator 1, large-scale vibrating screening machine 3, large-scale leaf topper 6 and large-scale air separator 7 after beating, wherein, several air separators 1 pass through The discharge belt conveyor 2 of the air separator is connected with the corresponding large vibrating screening machine 3, and the outlet of each large vibrating screening machine 3 is connected with the large collecting belt 4, so that the super large After the leaves are sieved by the large-scale vibrating screening machine 3, they are collected by the large-scale collection belt 4; the end of the large-scale collection belt 4 is connected with the large-scale leaf topper 6 through the vibrating conveyor 5, and the large-scale leaf topper 6 passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com