Integrated shoe pads, shoes with integrated shoe pads, and making method of shoes

An integrated, shoe lining technology, applied in shoe uppers, footwear, boot legs, etc., can solve the problems of complicated shoemaking processes, and achieve the effects of simple production, improved efficiency, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

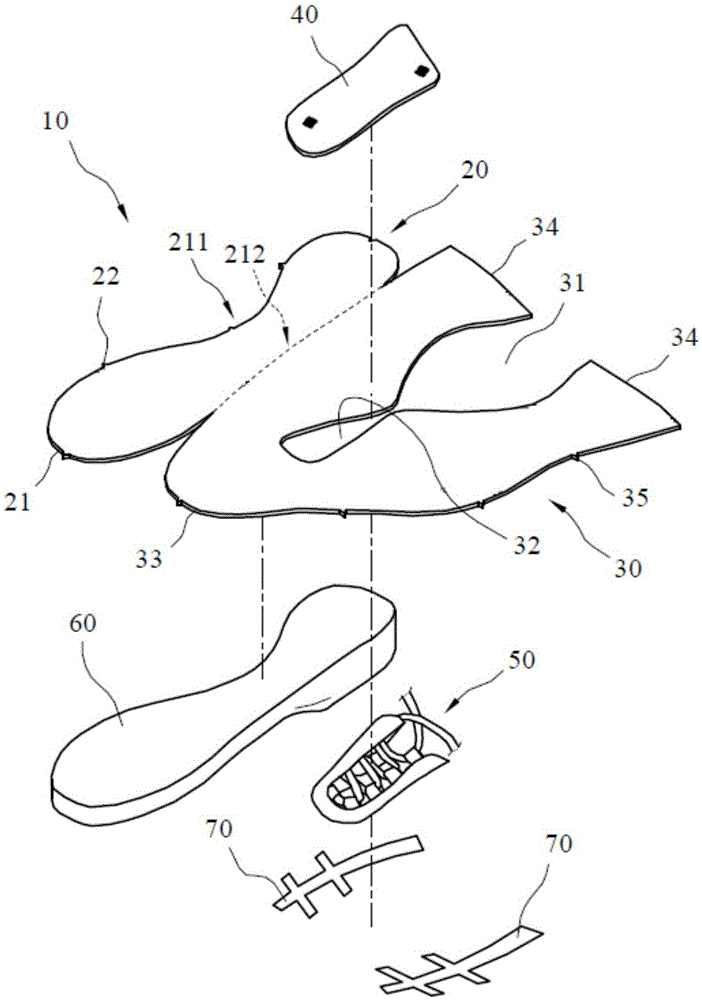

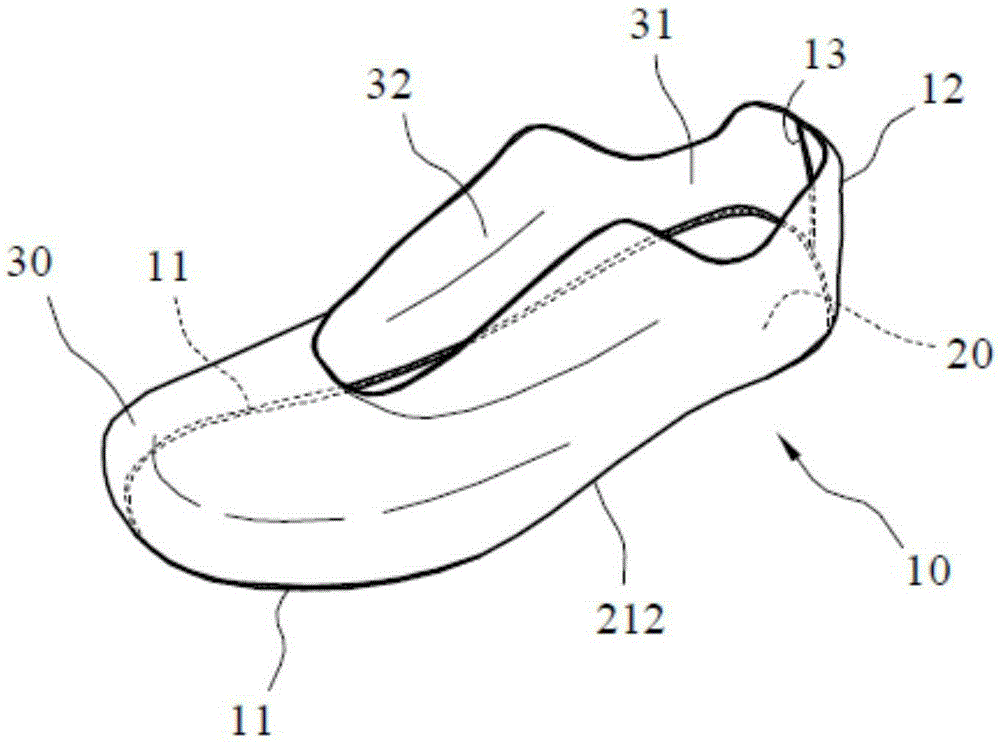

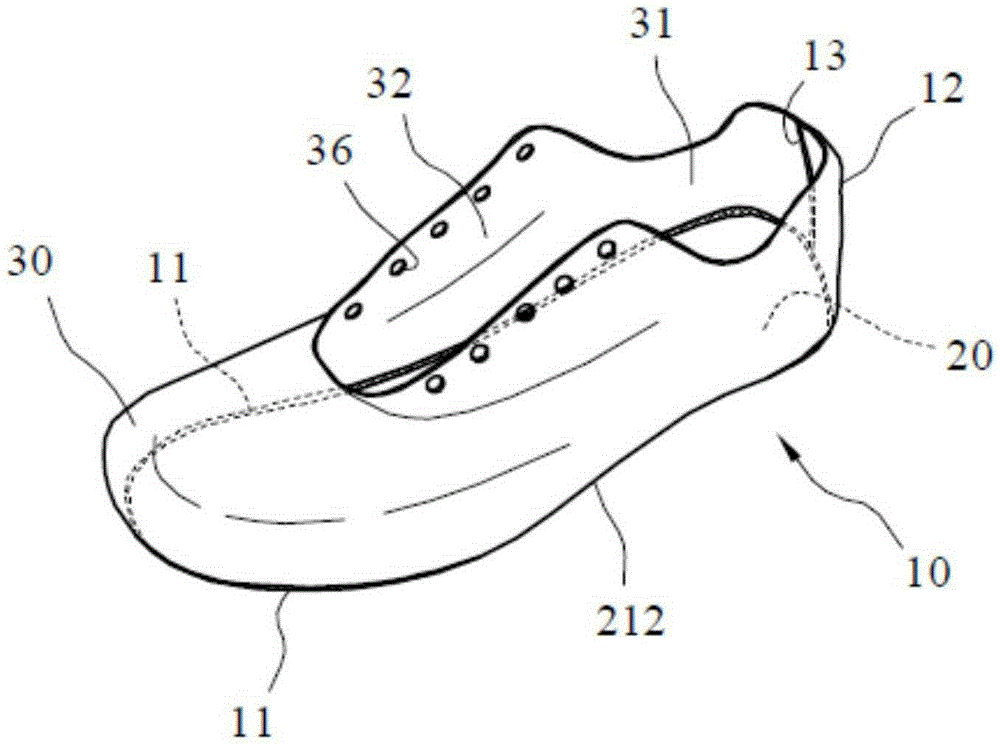

[0027] Shoe lining 10 of the present invention, please refer to figure 1 , figure 2 The shoe liner 10 is cut into the required planar shape according to the predetermined three-dimensional size of the shoe, and it has a substrate 20 and a lining surface 30. The edge of the substrate 20 forms a substrate edge 21, and the substrate edge 21 is provided with an inner edge 211 and an outer edge 212. , the inner edge 211 or the outer edge 212 can be extended with a lining 30, the lining 30 is formed with a shoe mouth 31 and a tongue 32, and its edge forms a lining edge 33 and a heel edge 34, along the lining edge 21, the lining edge 33 And the heel edge 34 is stitched or adhered, then the plane shoe lining 10 can be formed into a three-dimensional shoe lining 10, and the substrate edge 21 and the lining edge 33 that are stitched or adhered to each other form a seam line 11, and the stitched or adhered The heel edge 34 forms the rear heel 12 and the heel seam 13 .

[0028] The cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com