Air cylinder shell and air cylinder shell tool clamp

A technology for tooling fixtures and shells, which is applied in the direction of manufacturing tools, clamping, positioning devices, etc., can solve problems such as flattening of cylinder shells, easy inward depression of the outer wall, affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

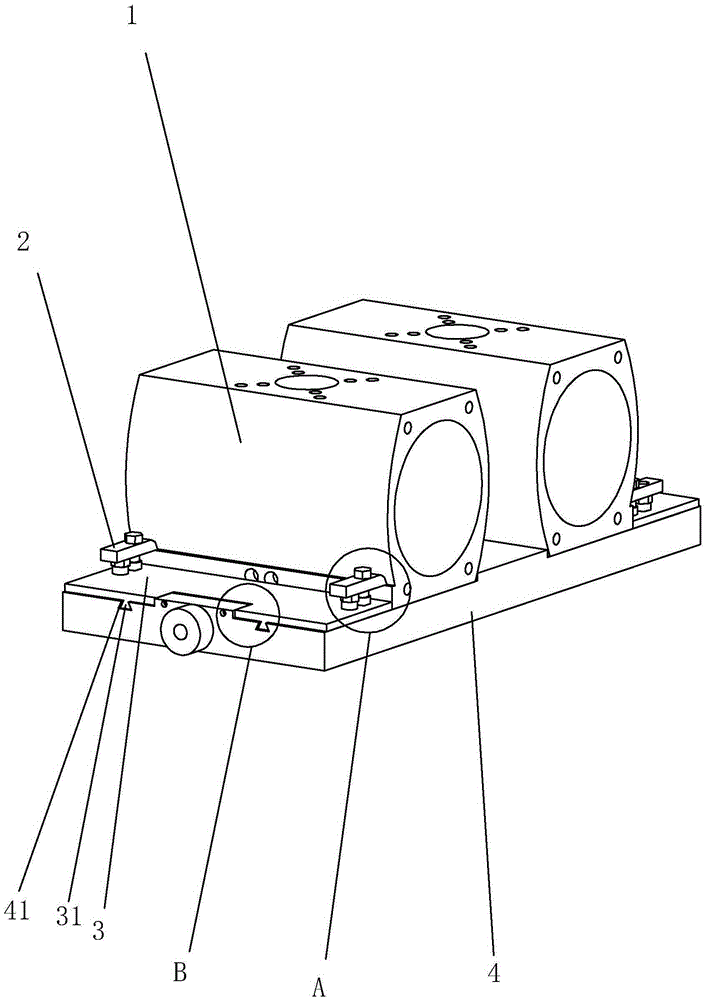

[0027] The embodiments of the present invention will be further described with reference to the accompanying drawings.

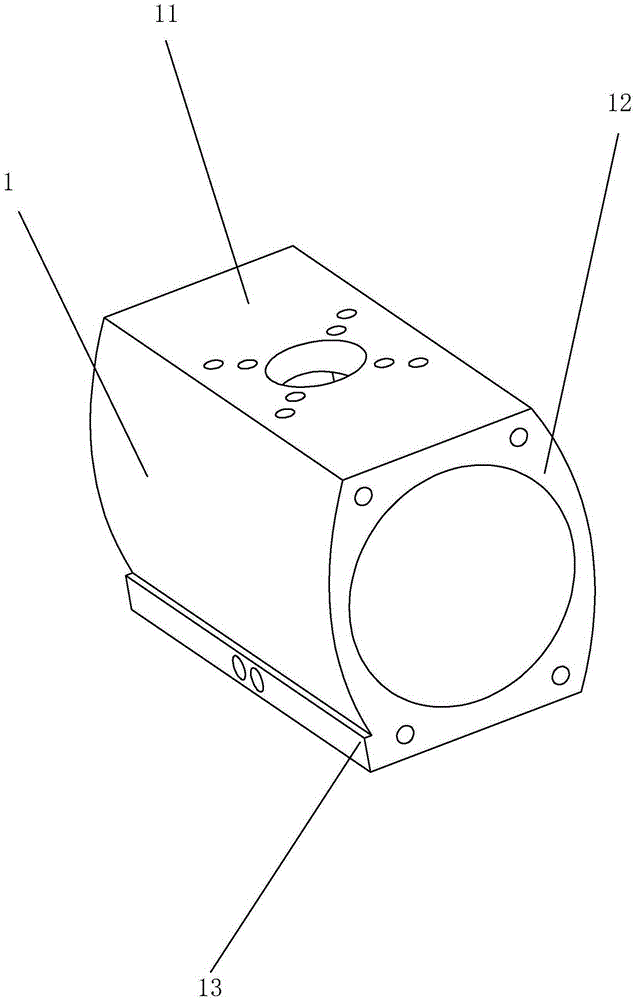

[0028] A cylinder housing includes a casing 1, the casing 1 includes four sides and two end faces 12, two opposite sides are formed with a placement plane 11, and the other two opposite sides are formed as arc surfaces, and the arc faces extend outward A clamping step 13 is formed. The clamping step 13 is close to the placement plane 11. The clamping step 13 is used for clamping the tooling fixture when the end face 12 is processed. After the tooling fixture clamps the clamping step 13, it is mainly the clamping step 13. The force is applied during processing, which can prevent the tooling fixture from being clamped on the surface of the cylinder casing, thereby avoiding the flattening of the cylinder casing.

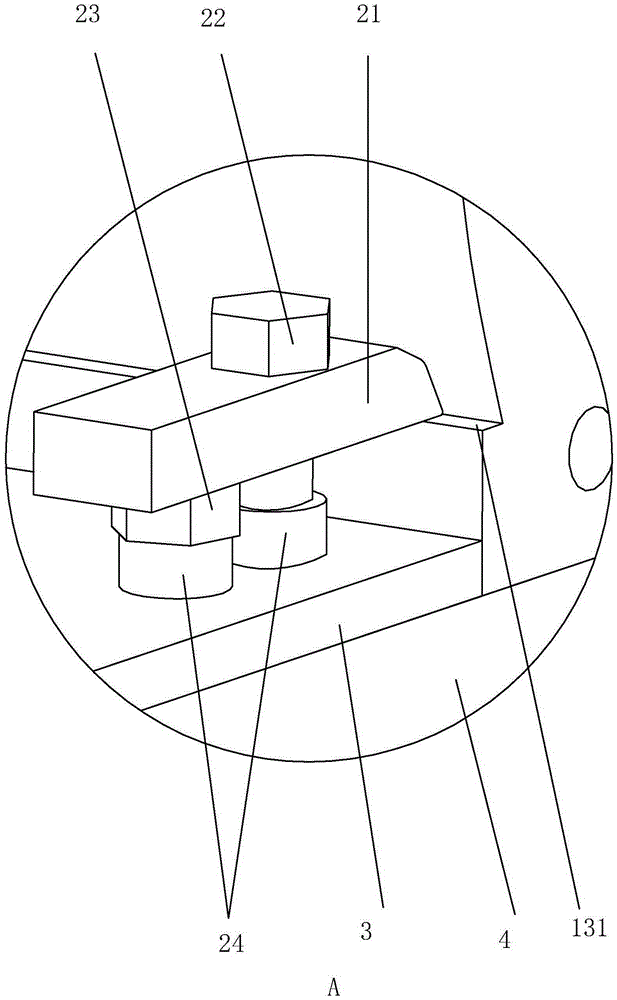

[0029] For more stable clamping of the cylinder shell, the clamping step 13 includes a clamping surface 131 and a positioning surface. The positionin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap