Novel controlling moment gyro framework assembly structure

A technology for controlling the torque gyroscope and component structure, which is applied in the direction of rotating gyroscopes, etc., can solve the problems of changing the loading state of high-speed bearings, affecting the power consumption, vibration level and working life of the control torque gyroscope, and achieves the reduction of micro-vibration level, Ensure accurate loading and reduce the power consumption of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

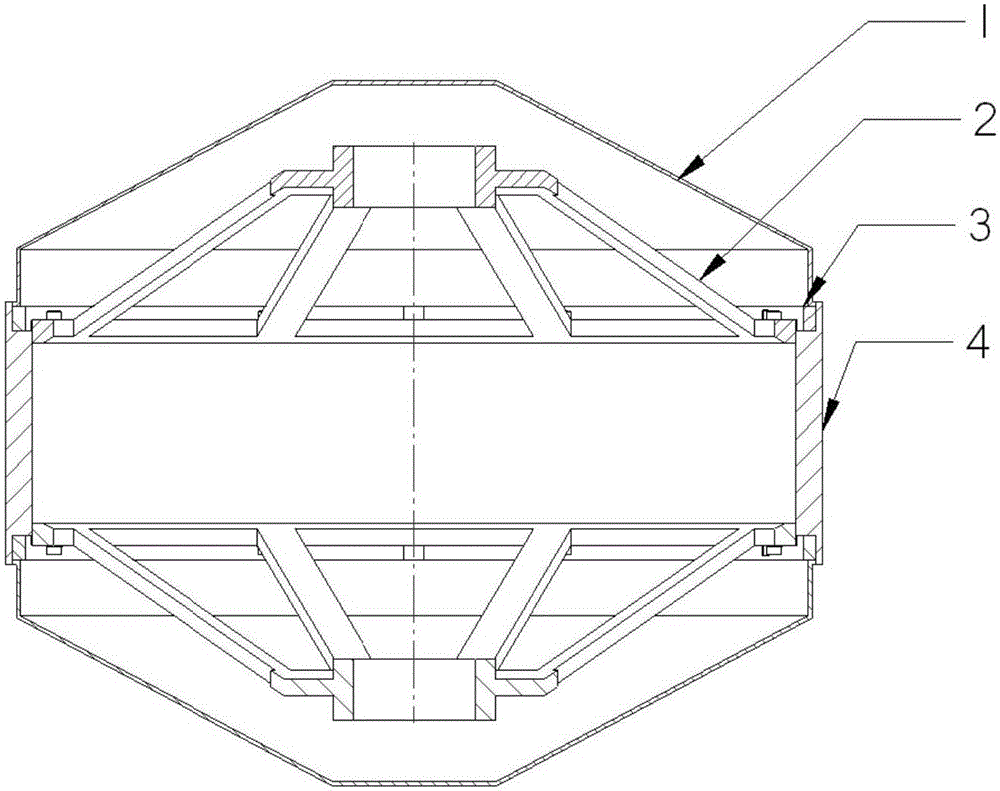

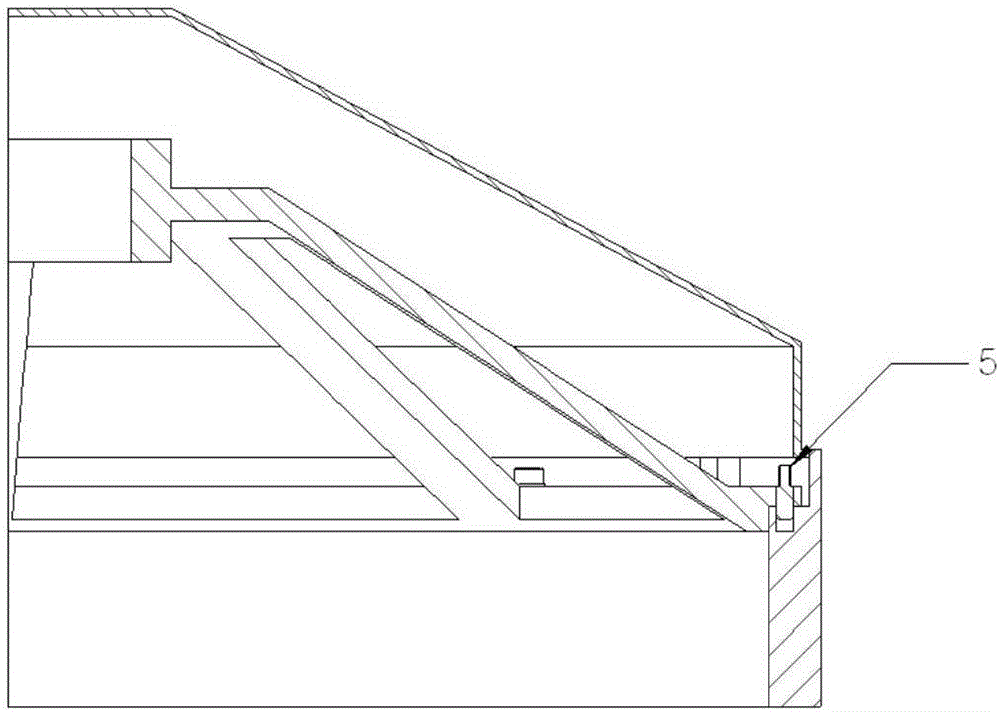

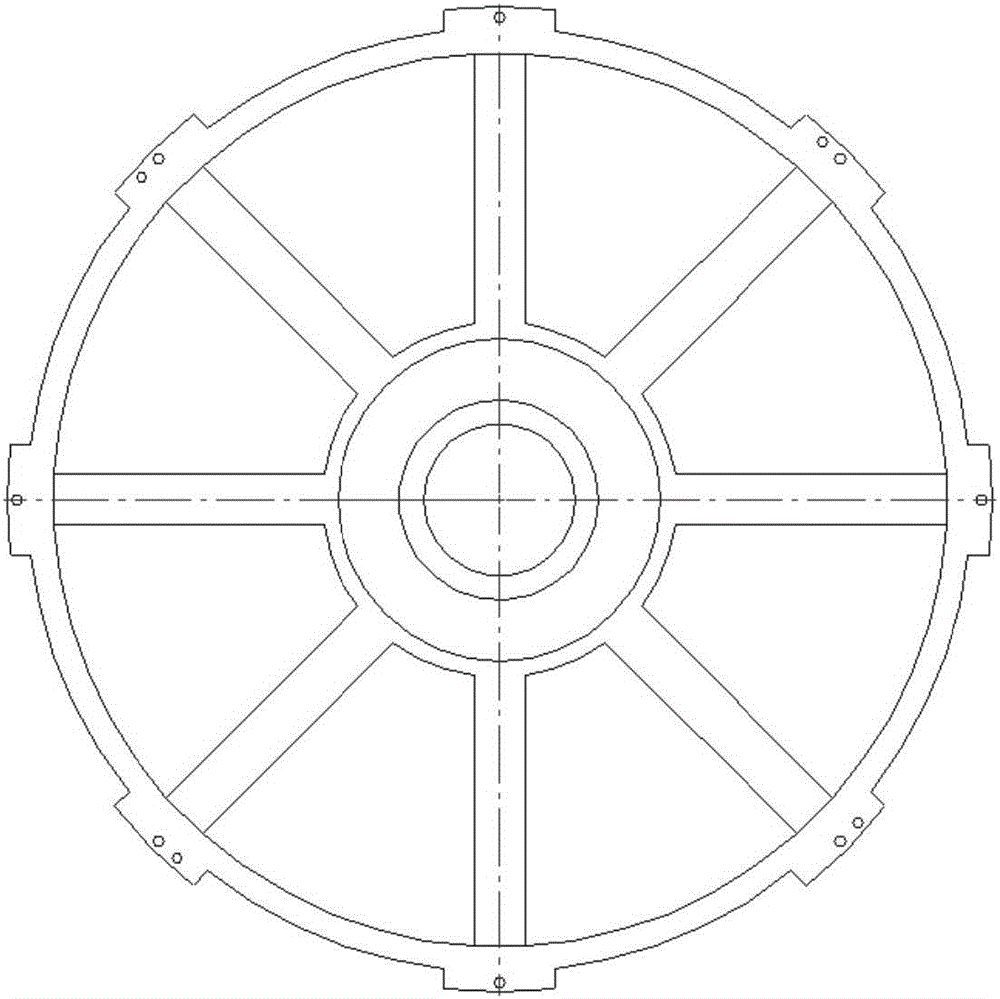

[0019] Such as Figure 1-4 As shown, the novel frame assembly structure of the present invention includes a sealing cover 1 , a frame width 2 , a sealing cover spacer 3 , a frame edge 4 and an externally threaded conical pin 5 . The sealing cover 1 is an arc-shaped thin shell, the frame width 2 is an eight-claw support structure, the sealing cover pad 3 is a solid block in the shape of a cuboid, and the frame edge 4 is a cylindrical shell. The externally threaded tapered pin 5 is an externally threaded structure at the other end of a conical cone. There are 2 frame widths 2 and 8 externally threaded conical pins 5. The externally threaded conical pins 5 position the frame width 2 on the upper and lower sides inside the frame edge 4, and then fasten the frame width 2 to the frame edge with screws The upper and lower ends of 4 are used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com