Method for detecting drainage failure of water use equipment

A water-based equipment and fault detection technology, applied in the direction of testing water, material inspection products, tableware washing machine/rinsing and washing machine parts, etc., can solve the problems of increasing the failure rate of related components, increasing machine costs, increasing hidden dangers of water leakage, etc., to achieve The detection method is simple and easy, the failure rate is reduced, and the effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

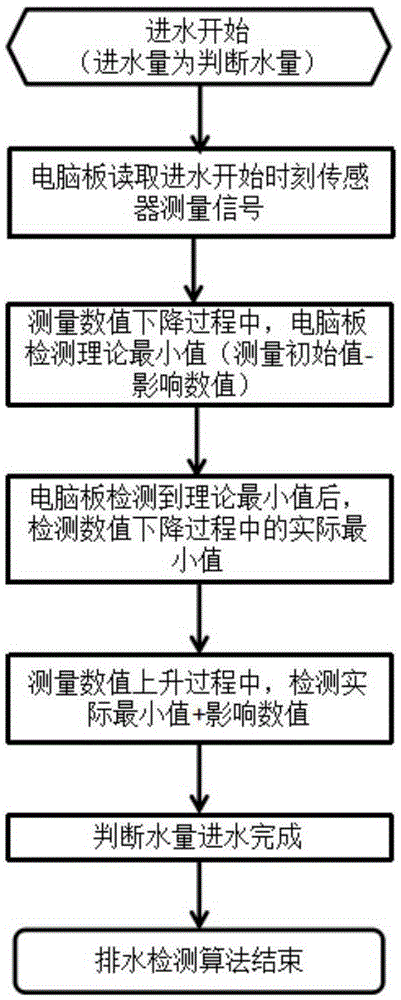

[0054] The drainage fault detection of the present invention utilizes the measurement signal of the turbidity sensor and combines with the drainage detection algorithm to realize the monitoring of the drainage situation. In the present invention, besides using the turbidity sensor for conventional dirty degree detection and temperature detection, a new function of drainage fault detection is developed.

[0055] The present invention will be described in detail below by taking a dishwasher as an example.

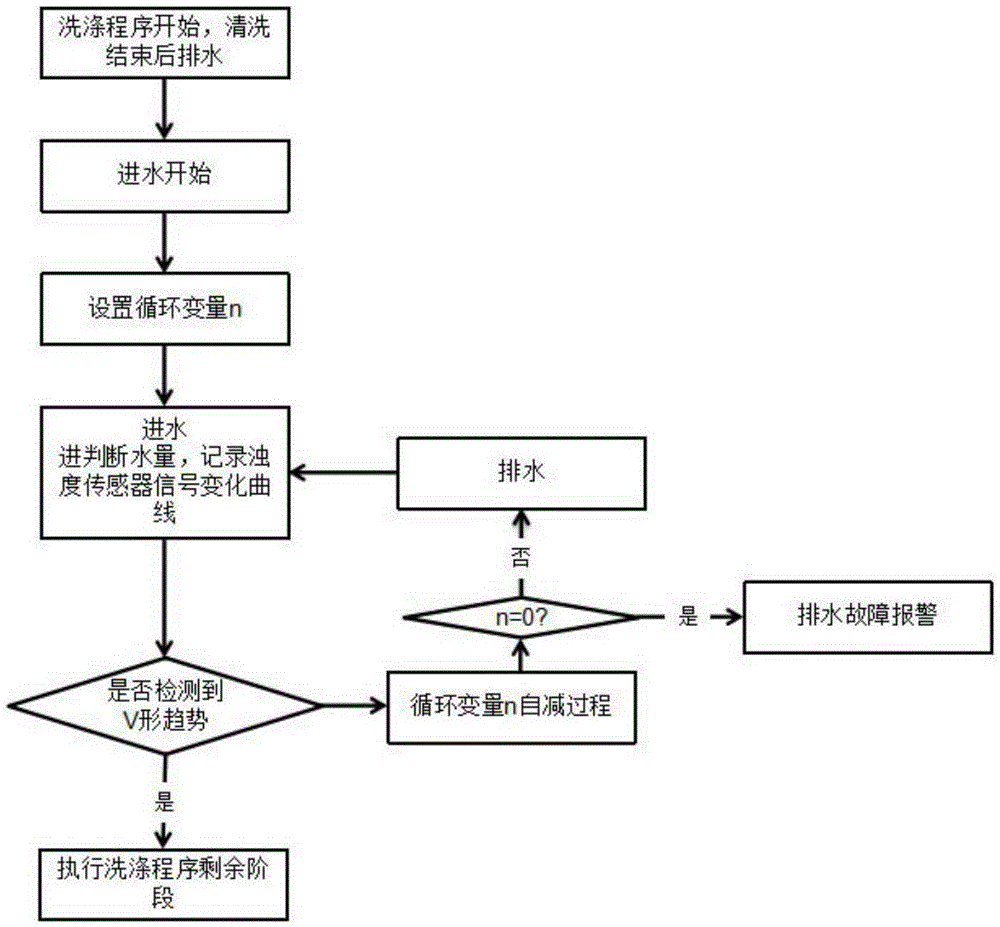

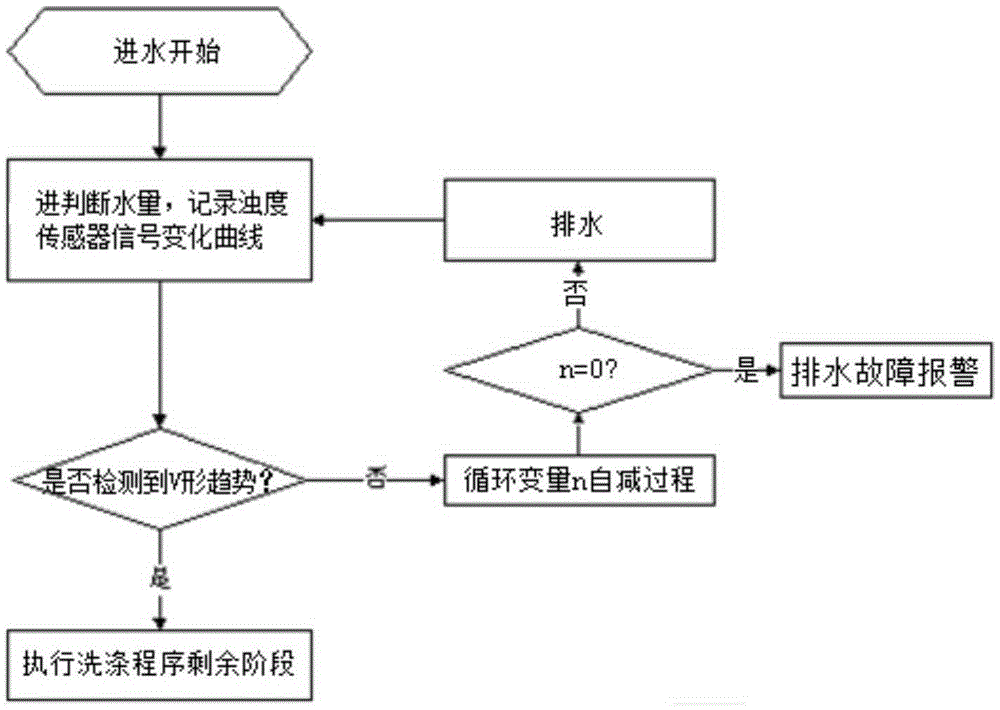

[0056] figure 1 Embodiment 1 of the drainage failure detection process provided by the present invention, such as figure 1 As shown, the method flow of utilizing the turbidity sensor for drainage fault detection provided by the present invention includes the following steps:

[0057] S1, the water intake program starts to run;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com