A method for extracting antioxidant active substances from waste sisal residue

A technology of antioxidant activity and sisal slag, which is applied in the directions of antitoxins, pharmaceutical formulations, and drug combinations, can solve the problems of resource waste, ecological environment pollution, affecting the ecological environment of river water, etc., and achieves improved utilization, high extraction rate, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

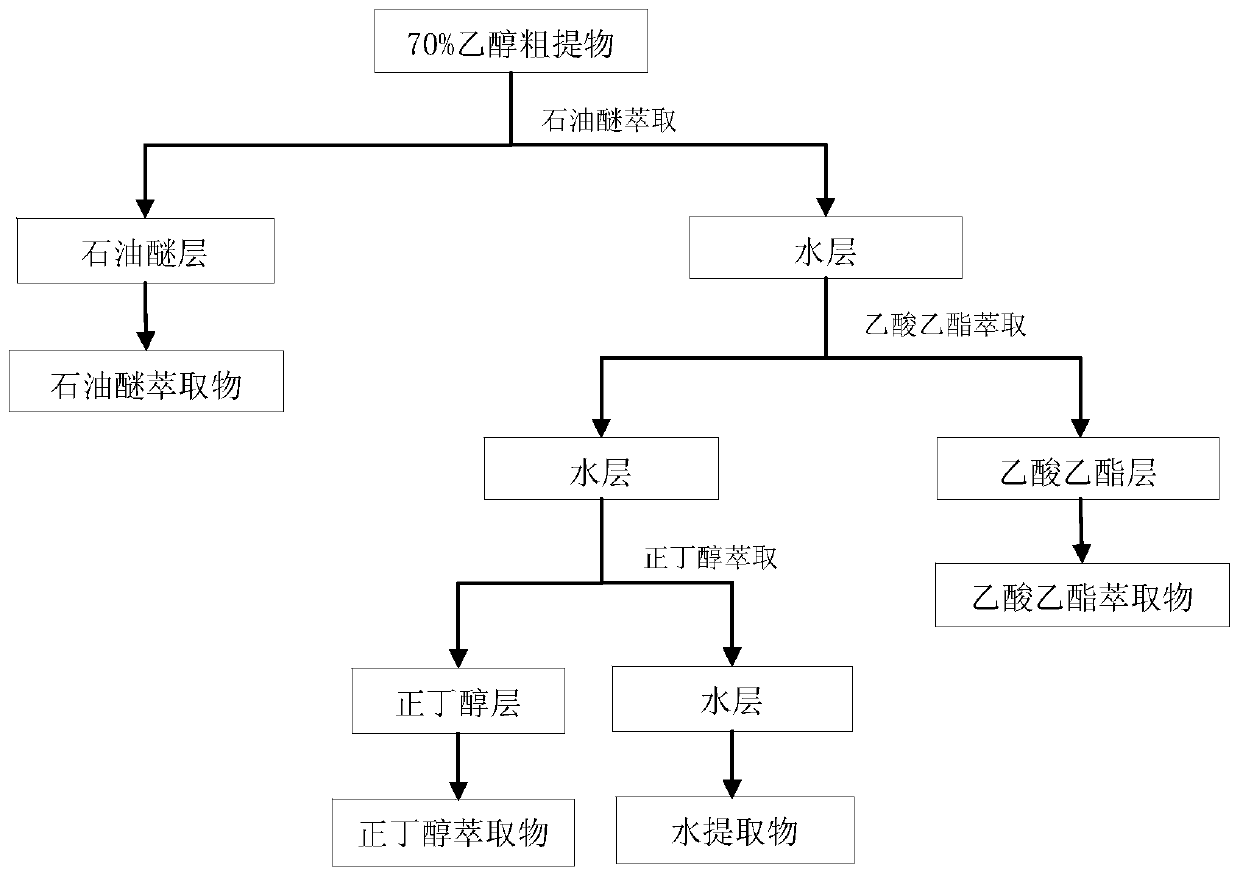

Embodiment 1

[0031] The sisal slag after extracting the fiber is washed with clean water several times to remove impurities until the cleaning solution is nearly colorless, and air-dried at 60°C for 10 hours. The dried sisal slag is crushed with a plant micro-pulverizer for 10 minutes, and passed through a 60-mesh sieve. , sealed in a sample bag, and stored in a dry place at room temperature; weigh a certain amount of sisal residue powder, use 70% ethanol to reflux extract three times according to the ratio of solid to liquid at 1:20, the extraction temperature is 60 ° C, filter, combine the filtrate, and use Concentrate under reduced pressure on a rotary evaporator at 50°C to the extract to obtain crude ethanol extract; dissolve the ethanol extract in water, transfer it to a separatory funnel, add 2 times the volume of petroleum ether, shake, stand still, and separate layers Finally, the upper petroleum ether layer was separated, and the lower aqueous solution was extracted twice by the sa...

Embodiment 2

[0034] The sisal slag after extracting the fiber is washed with clean water several times to remove impurities until the cleaning solution is nearly colorless, and air-dried at 60°C for 10 hours. The dried sisal slag is crushed with a plant micro-pulverizer for 10 minutes, and passed through a 60-mesh sieve. , sealed in a sample bag, and stored in a dry place at room temperature; weigh a certain amount of sisal residue powder, use 70% ethanol to reflux extract three times according to the ratio of solid to liquid at 1:10, the extraction temperature is 70 ° C, filter, combine the filtrate, and use Concentrate under reduced pressure on a rotary evaporator at 55°C to obtain extracts to obtain crude ethanol extracts; dissolve the ethanol extracts in water, transfer them to a separatory funnel, add petroleum ether twice the volume, shake, stand still, and separate layers Finally, the upper petroleum ether layer was separated, and the lower aqueous solution was extracted twice by the...

Embodiment 3

[0036] The sisal slag after extracting the fiber is washed with clean water several times to remove impurities until the cleaning solution is nearly colorless, and air-dried at 60°C for 10 hours. The dried sisal slag is crushed with a plant micro-pulverizer for 10 minutes, and passed through a 60-mesh sieve. , sealed in a sample bag, stored in a dry place at room temperature; weigh a certain amount of sisal slag powder, use 70% ethanol to reflux extract three times according to the ratio of solid to liquid at 1:15, the extraction temperature is 80 ° C, filter, combine the filtrate, and use Concentrate under reduced pressure on a rotary evaporator at 60°C to extract to obtain crude ethanol extract; dissolve the ethanol extract in water, transfer it to a separatory funnel, add petroleum ether twice the volume, shake, stand still, and separate layers Finally, the upper petroleum ether layer was separated, and the lower aqueous solution was extracted twice by the same method, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com