LED lamp filament gluing device

A technology of LED filament and glue coating device, which is applied to the device, coating, pretreatment surface and other directions of surface coating liquid, can solve the problems of colloid peeling, affecting luminosity, increasing labor cost, etc., to reduce bubbles, improve Product quality, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

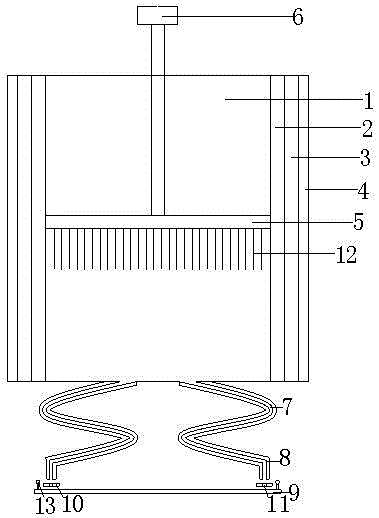

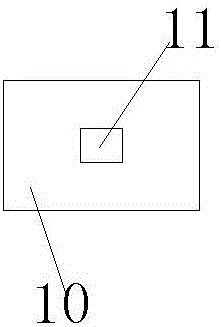

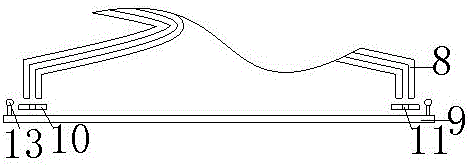

[0015] Such as Figure 1-3 As shown, the present invention is a LED filament gluing device, comprising a glue barrel 1, a ceramic heat transfer cylinder 2 is arranged on the outside of the glue barrel 1, an electric heating layer 3 is arranged on the outside of the ceramic heat transfer cylinder 2, The heat of the motor heating layer 3 is transferred to the rubber barrel through the ceramic heat transfer cylinder, and the heating is even. An anti-scald layer 4 is set outside the electric heating layer 3 to avoid scalding the staff. Material plate 5, several probes 12 are set below the binder plate 5, the probes can pierce the air bubbles in the glue to reduce the num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com