Control method for reducing crystallization risk in scr urea injection system

The technology of a urea injection system and a control method is applied in the control field of reducing the crystallization risk of the SCR urea injection system, and can solve problems such as the wall attachment effect of the urea injection system, so as to improve reliability, reduce the risk of freezing cracks, prolong purging or The effect of suck time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

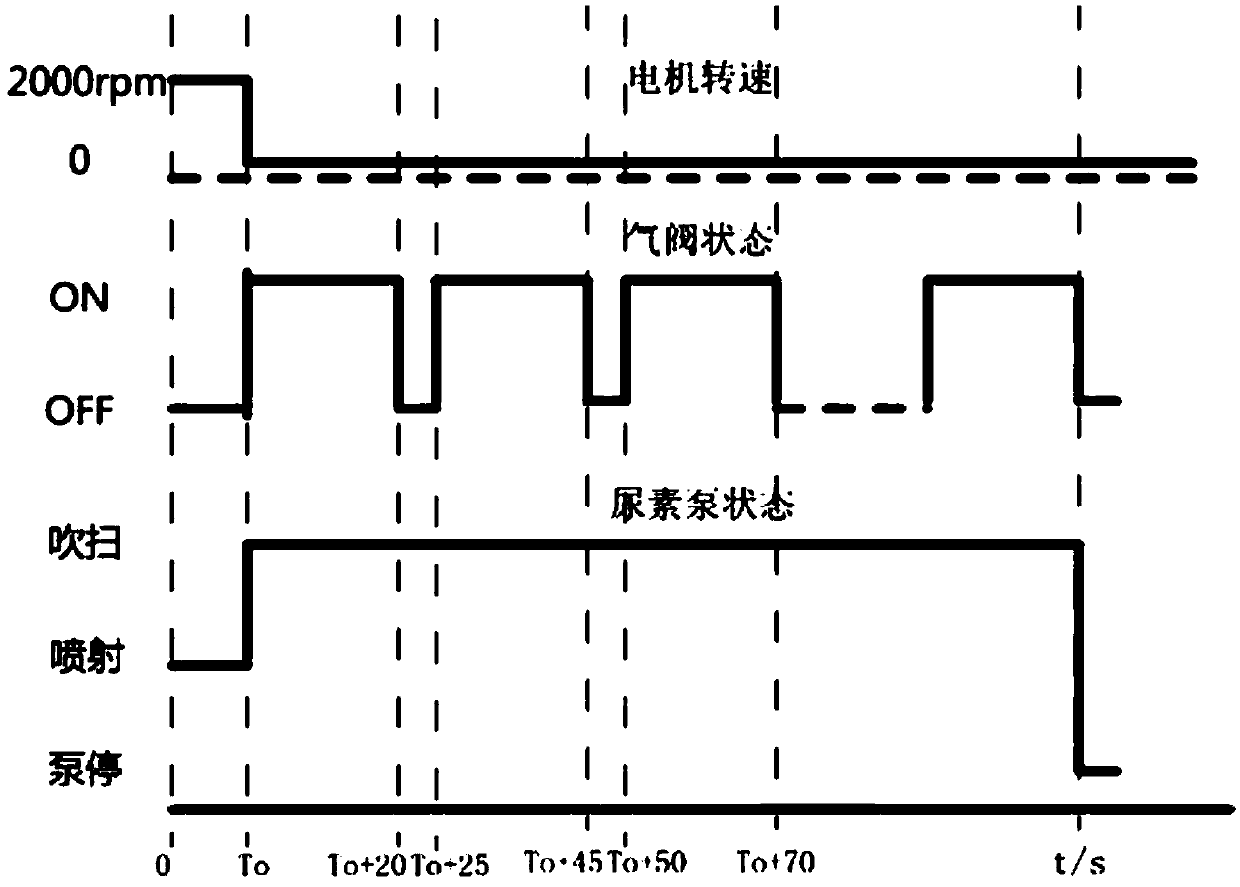

[0043] Such as figure 1 As shown, in the first embodiment of the present invention, a control method for reducing the crystallization risk of the SCR urea injection system is provided, and the control method includes the following steps:

[0044] S1: When the SCR urea injection system (for example, an air-assisted SCR urea injection system) changes from the injection state of injecting urea to the purging state of purging the urea solution existing in the pipeline (for example, through the SCR urea injection system) The electronic control unit judges that the SCR urea injection system changes from the injection state of injecting urea to the purging state of purging the urea solution existing in the pipeline, or, through the electronic control unit of the SCR urea injection system, the SCR urea injection system is switched from injecting urea to After the spraying state is transferred to the purging state of purging the urea solution existing in the pipeline), the air valve of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com