Hydraulic mount and its assembly, control method, control unit, ecu and automobile

A control unit and hydraulic mount technology, which are applied in the fields of control methods, control units, ECUs and automobiles, hydraulic mounts and their assemblies, and can solve problems such as the inability of hydraulic mounts to adjust stiffness in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

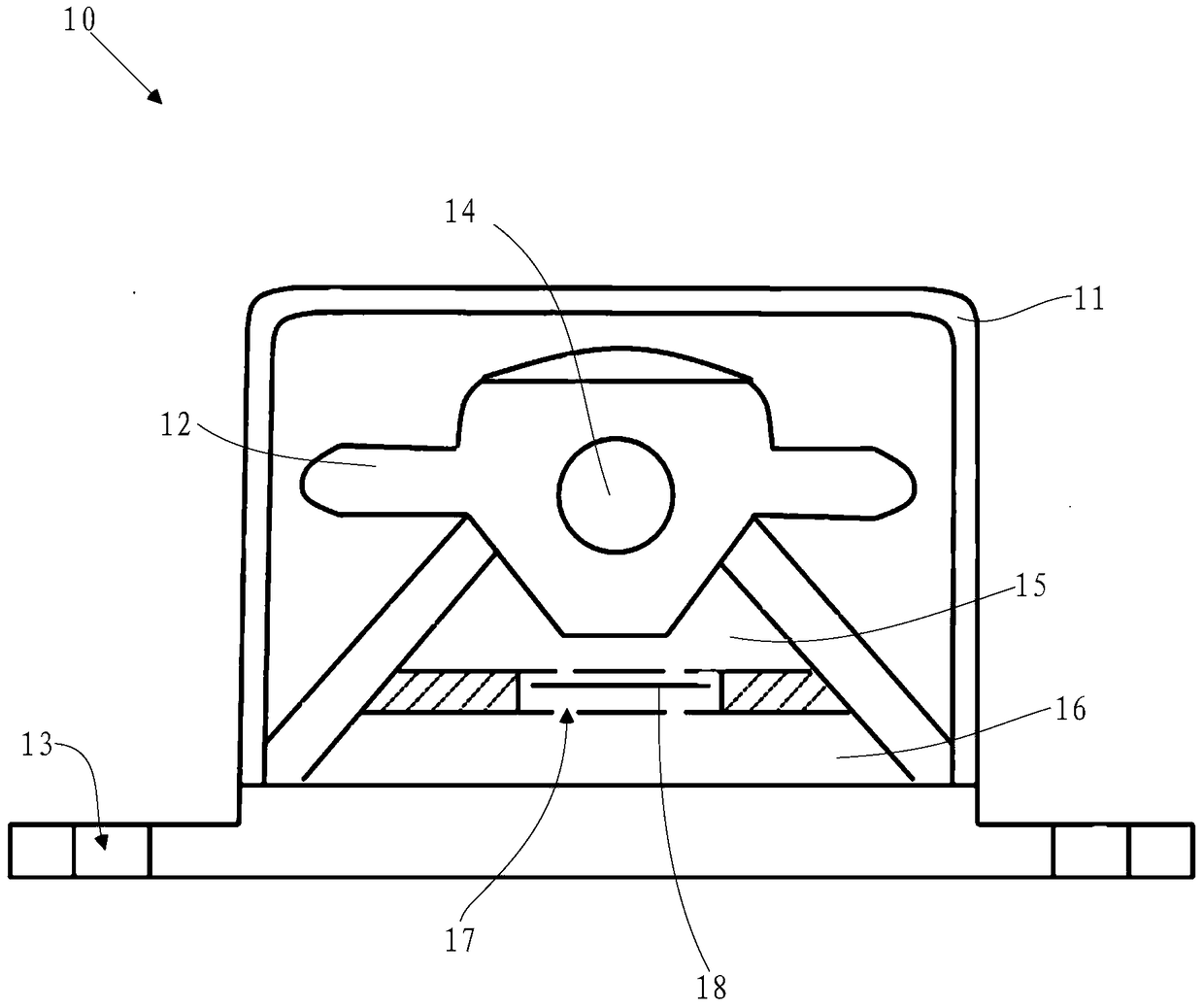

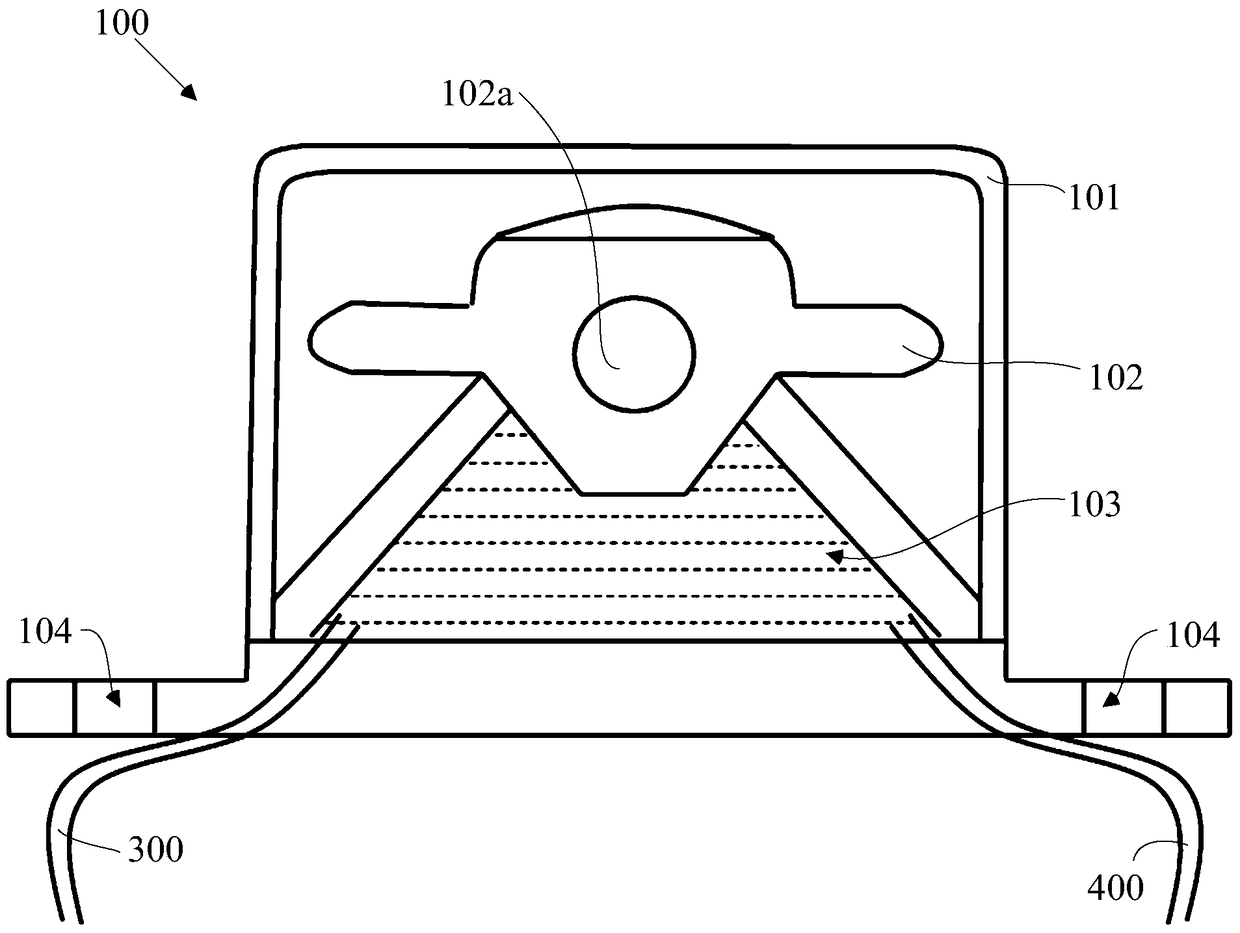

[0077] refer to figure 2 The embodiment of the present invention provides a hydraulic mount 100, comprising: a housing 101 having an inner cavity, the housing 101 is made of metal, and the hydraulic mount 100 further includes: a rubber main spring 102 located in the inner cavity; The rubber main spring 102 and the bottom wall of the housing 101 form a hydraulic chamber 103, which is filled with liquid, which is ethylene glycol in this embodiment; the rubber main spring 102 is provided with a mounting bracket 102a for use with The engine (not shown in the figure) is connected, and the casing 101 is used to connect with the automobile body, specifically: the casing 101 is provided with a bolt hole 104, and the casing 101 is installed on the automobile body by installing a bolt in the bolt hole 104. On the vehicle body, in this embodiment, the housing 101 is installed on the longitudinal beam of the vehicle body.

[0078] The hydraulic chamber 103 communicates with the outside ...

Embodiment 2

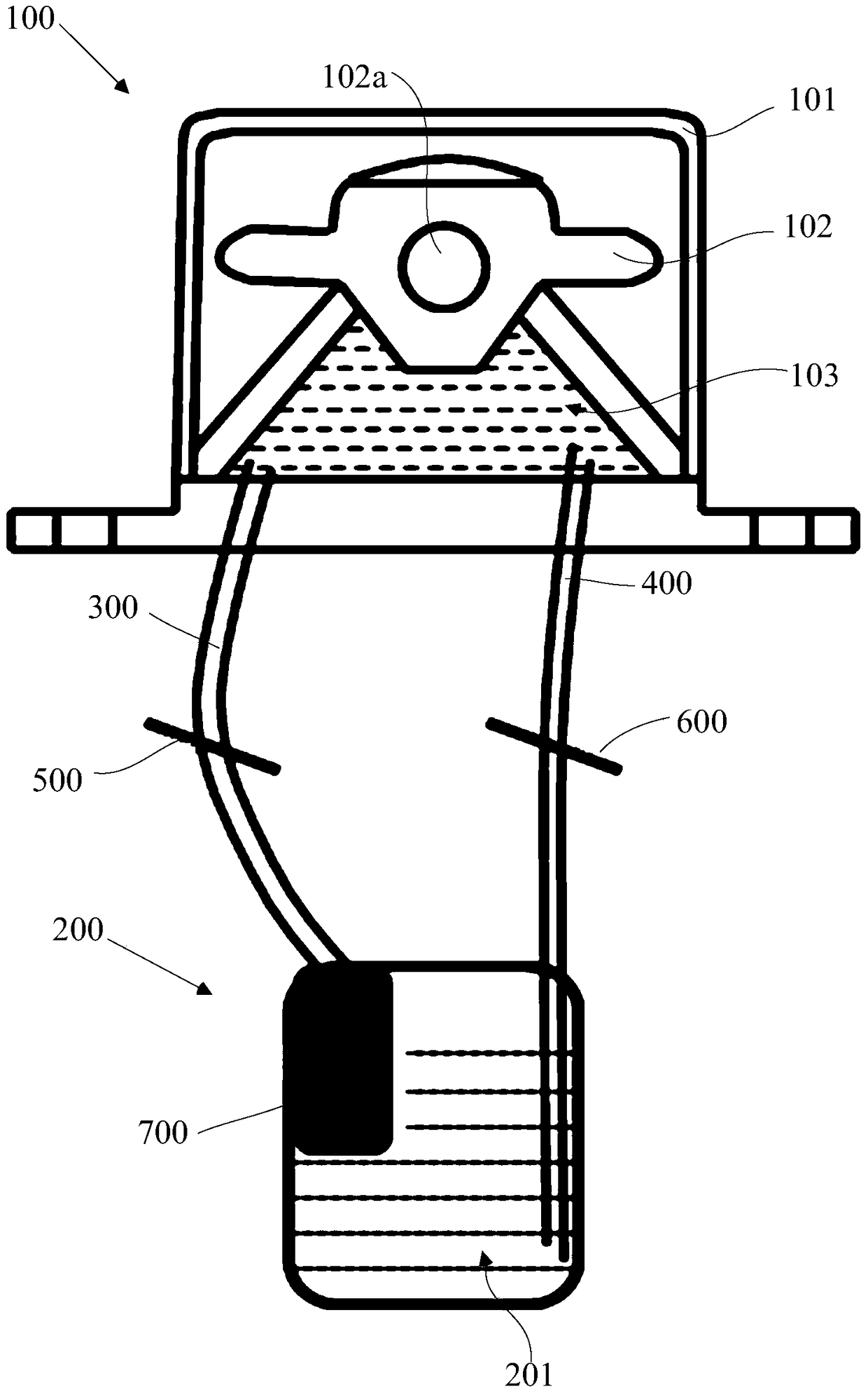

[0082] A hydraulic mount assembly is provided in this embodiment, refer to image 3 and combine figure 2 As shown, it includes a hydraulic mount 100 and a liquid storage bottle 200, the inner chamber 201 of the liquid storage bottle 200 is also filled with liquid, and the liquid storage bottle 200 communicates with the hydraulic chamber 103 in the hydraulic mount 100 through pipe fittings; in this embodiment , the pipe fittings include a first pipe fitting 300 and a second pipe fitting 400, the first pipe fitting 300 is provided with a first valve 500, and the second pipe fitting 400 is provided with a second valve 600, in this embodiment, the first valve 500 and the second valve 600 are solenoid valves; oil inlet and outlet are provided on hydraulic chamber 103, and oil inlet and outlet are also provided on liquid storage bottle 200, thus, the oil inlet and liquid storage on hydraulic chamber 103 The oil inlet on the bottle 200 communicates through the first pipe 300 ; the ...

Embodiment 3

[0087] In this embodiment, the flow of liquid between the hydraulic chamber 103 and the liquid storage bottle 200 is controlled by the first valve 500, the second valve 600 and the pumping device 700, and the pumping device 700 is a pump in this embodiment; The opening or closing of the first valve 500, the second valve 600 and the pump is controlled by the suspension assembly control unit, refer to Figure 4 , when the suspension assembly control unit determines that the stiffness of the hydraulic mount 100 needs to be increased, the suspension assembly control unit sends a first instruction, the first instruction is: send an opening instruction to the first valve 500 and the pump, and send an opening instruction to the second valve 500. The valve 600 sends a closing command; then, the first valve 500 is opened, the pump works, the second valve 600 is closed, and the liquid flows from the liquid storage bottle 200 to the hydraulic chamber 103 through the first pipe 300 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com