A tapered shock absorber with adjustable stiffness and its installation and adjustment method

A shock absorber and rigidity technology, which is applied in the field of vibration reduction, can solve the problems of reduced system vibration reduction effect, affecting the normal operation of the generator, and heavy management workload, etc., so as to improve the service life, increase the adjustment range, and facilitate use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

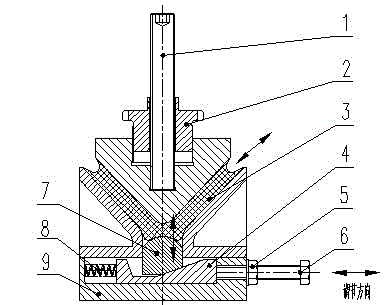

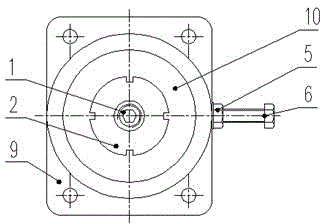

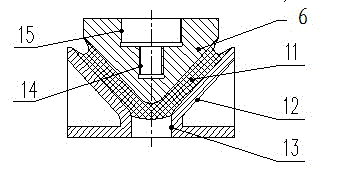

[0037] Embodiment 2 differs from Embodiment 1 in that the stiffness adjustment device includes a top block 7 and an adjustment bolt 6; the adjustment bolt 6 is provided with a lock nut 5, and the base 9 is provided with an inverted cone with the support seat 12. The supporting top block 7 positioning grooves of the guide hole 13 at the bottom of the groove; an adjusting screw hole is provided in the positioning groove; the adjusting bolt 6 is arranged in the adjusting screw hole; the top block 7 is arranged in the guide hole 13 and the top block 7 positioning grooves, The top block 7 and the guide hole 13 are in clearance fit, screwing in the adjusting bolt 6 can drive the top block 7 to move upward along the guide hole 13, and compress the elastic rubber body 11 of the elastic body, thereby increasing the stiffness of the shock absorber; The adjusting bolt 6 can drive the top block 7 to move down along the guide hole 13, and the pre-compression of the elastic rubber body 11 of...

Embodiment 3

[0038] Embodiment 3 is different from Embodiments 1 and 2 in that the angle of the inverted tapered groove on the upper part of the support seat 12 is 30°.

Embodiment 4

[0039] Embodiment 4 is different from Embodiments 1 and 2 in that the angle of the inverted tapered groove on the upper part of the support seat 12 is 85°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com