A real-time adjustment method for the stiffness of the probe of an atomic force microscope

An atomic force microscope and real-time adjustment technology, applied in scanning probe technology, scanning probe microscopy, instruments, etc., can solve problems such as narrow application range, complex structure, and cantilever beam failure, so as to reduce probe loss and work The effect of a wide range and a large adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

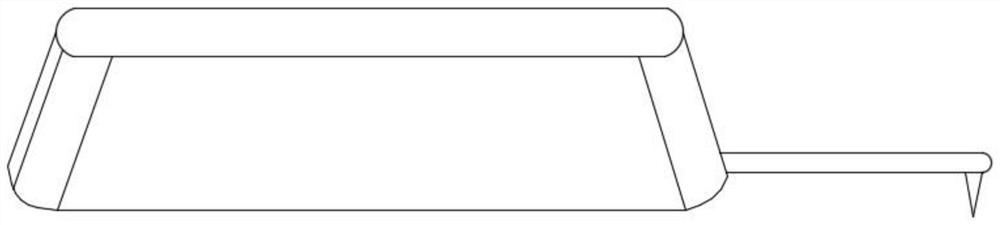

[0041] refer to figure 1 As shown, the invention discloses a real-time adjustment method for the stiffness of a probe of an atomic force microscope, comprising the following steps:

[0042] S1. A cantilever beam is coated with a stiffness adjustment layer to form a cantilever beam-coating composite. The stiffness adjustment layer is a metal layer, and the melting point of the metal layer is lower than that of the cantilever beam.

[0043] The metal layer is an alloy composed of one or more of indium, bismuth, tin and gold.

[0044] The stiffness adjustment layer is prepared by methods such as coating method, electron beam sputtering method, chemical vapor deposition method or focused ion beam deposition method.

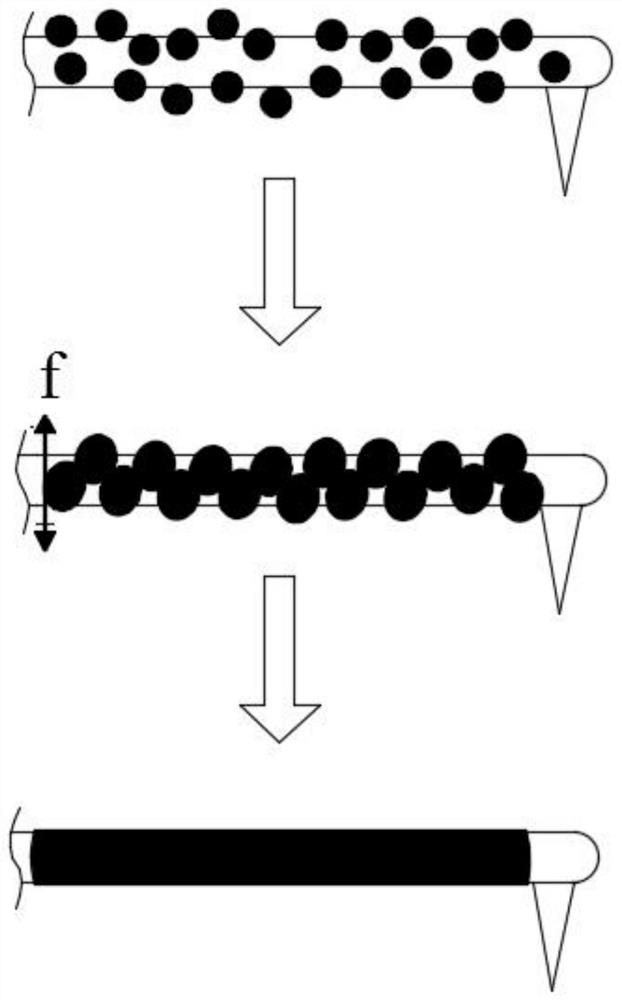

[0045] S2. Change the stiffness of the cantilever beam-coating composite by changing the temperature of the stiffness adjustment layer, specifically including:

[0046] S21, heating the probe, melting the metal layer on the cantilever beam, and obtaining molten met...

Embodiment 2

[0061] The invention discloses a method for adjusting the stiffness of a probe of an atomic force microscope in real time, comprising the following steps:

[0062] S1. A cantilever beam is coated with a stiffness adjustment layer to form a cantilever beam-coating composite. The stiffness adjustment layer is a metal layer, and the melting point of the metal layer is lower than that of the cantilever beam.

[0063] The metal layer is an alloy composed of one or more of indium, bismuth, tin and gold.

[0064] The stiffness adjustment layer is prepared by methods such as coating method, electron beam sputtering method, chemical vapor deposition method or focused ion beam deposition method.

[0065] S2. Change the stiffness of the cantilever beam-coating composite by changing the temperature of the stiffness adjustment layer, specifically including:

[0066] S21, heating the probe, melting the metal layer on the cantilever beam, and obtaining molten metal in a molten state;

[0...

Embodiment 3

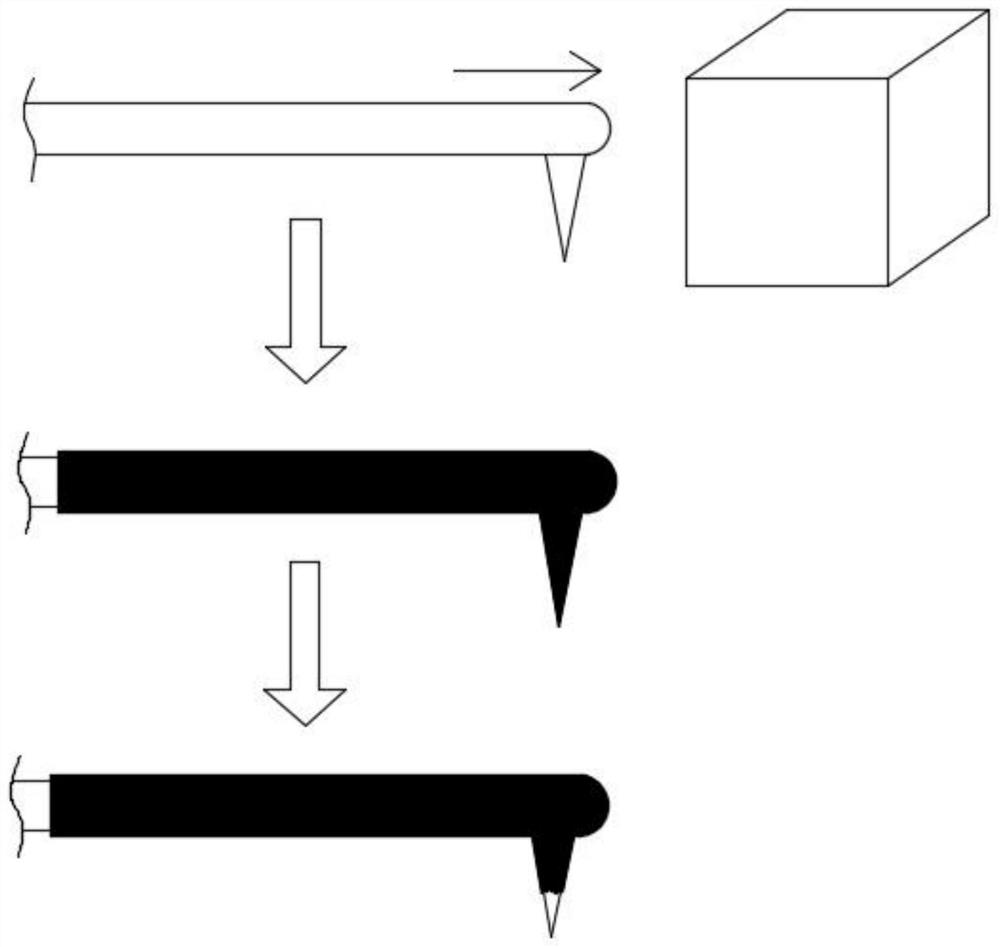

[0077] refer to figure 2 As shown, the invention discloses a real-time adjustment method for the stiffness of a probe of an atomic force microscope, comprising the following steps:

[0078] S1. The probe is heated so that the temperature of the probe is higher than the melting point of the non-conductive material. Non-conductive materials have a melting point below 100°C. The non-conductive material is resin material, polyethylene, polypropylene or rubber.

[0079] S2, immersing the heated probe in the non-conductive material and staying there;

[0080] S3. Pull out the probe from the non-conductive material. At this time, the surface of the probe is coated with a non-conductive material, stop heating the probe, and the non-conductive material solidifies and forms on the probe;

[0081] S4, scrape off the non-conductive material on the needle tip. In this embodiment, after the atomic force microscope probe "wraps" the non-conductive material, the needle tip needs to be sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stiffness | aaaaa | aaaaa |

| stiffness | aaaaa | aaaaa |

| stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com