Backlight module and manufacturing method thereof

A backlight module and backlight technology, applied in light guides, optics, optical components, etc., can solve problems such as color cast at the edge of the display screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

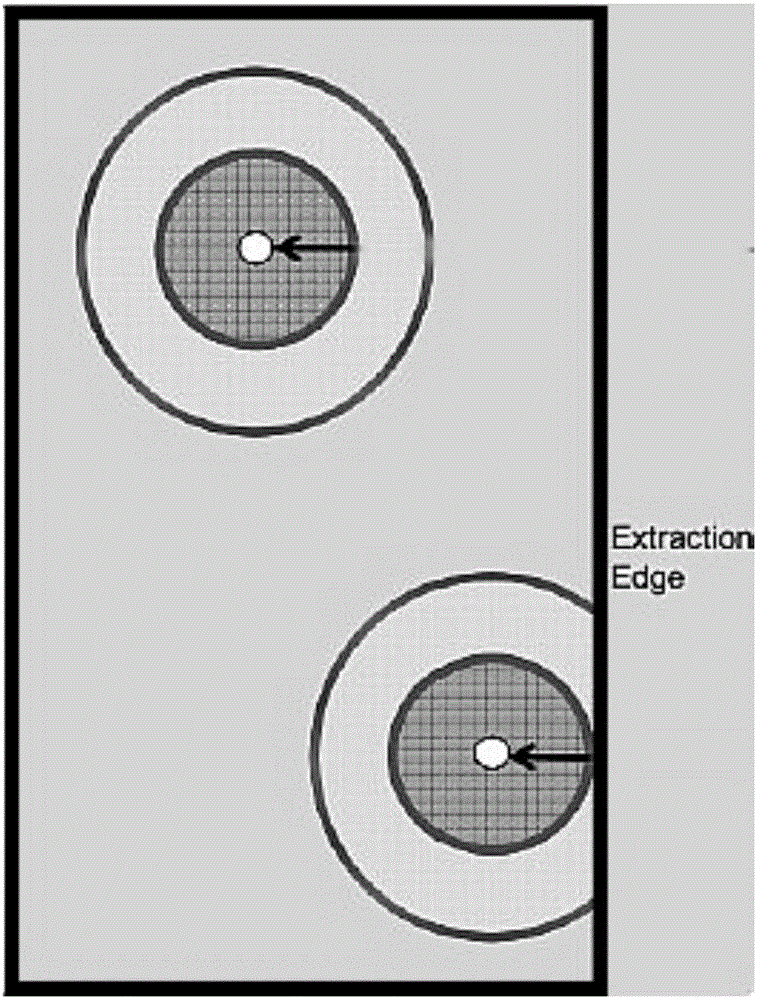

[0054] As described in the background of the present invention, the light guide plate of a backlight module in the prior art is because the color of the white point in the central area of the screen is composed of blue light in a small area and red light in a larger area of the quantum film or fluorescent film. Light and green light are mixed, and the red light and green light beyond the blue light area are produced by the excitation of blue light in other areas. For a certain point close to the edge position, the blue light area remains unchanged, while the red light and green light areas beyond the blue light area are reduced by the blue light irradiation received by the quantum film or phosphor film, so the red light and green light components are reduced, thus Caused the problem that the color of the blend point was blue.

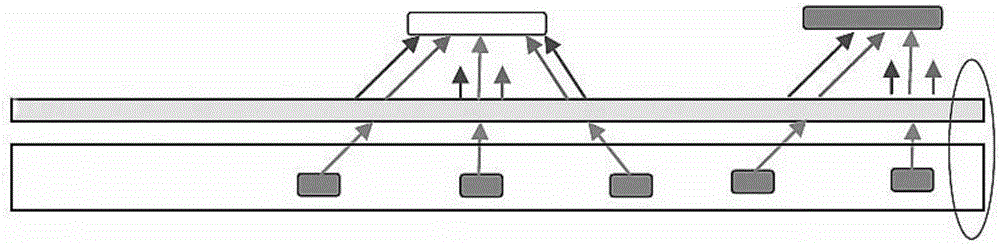

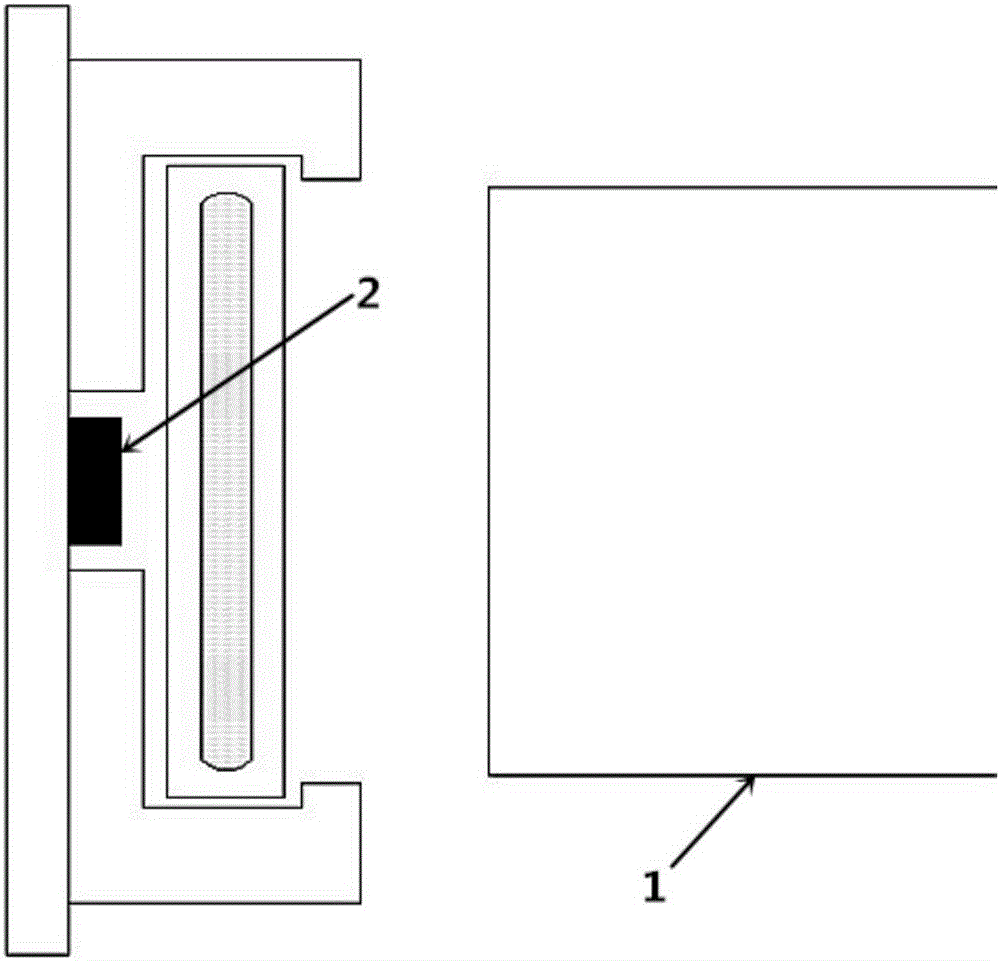

[0055] In addition, another backlight module in the prior art encapsulates the quantum dot material in a glass tube as a line light source and plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com