Designed compaction number-of-times determining method of emulsified asphalt cold recycled mixture

A technology of cold recycled mixture and recycled mixture, which is applied in design optimization/simulation, calculation, electrical digital data processing, etc., can solve problems such as research on compaction characteristics of cold recycled mixture without emulsified asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

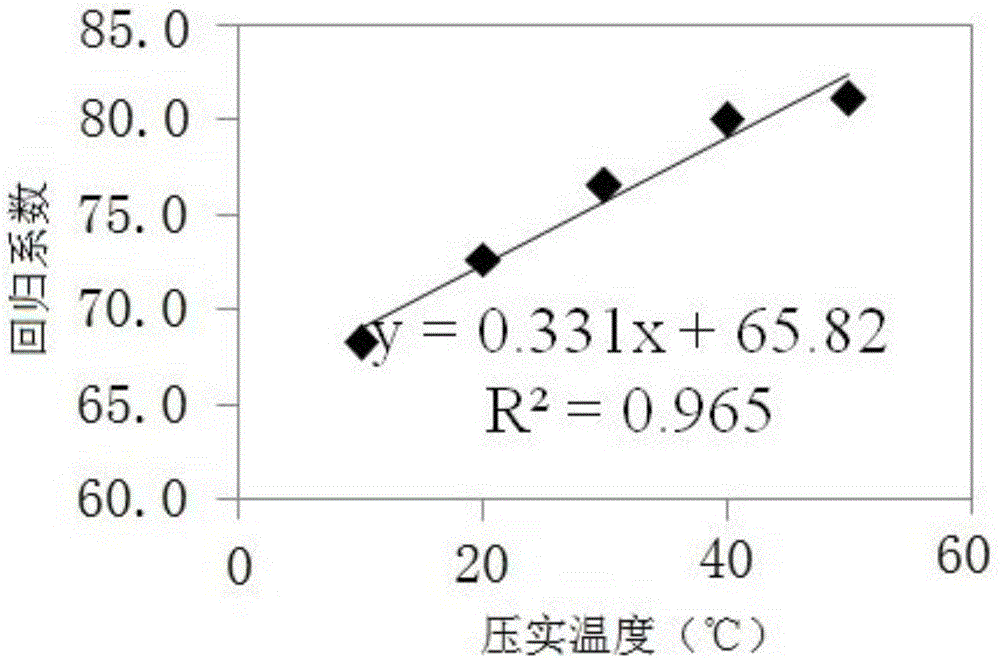

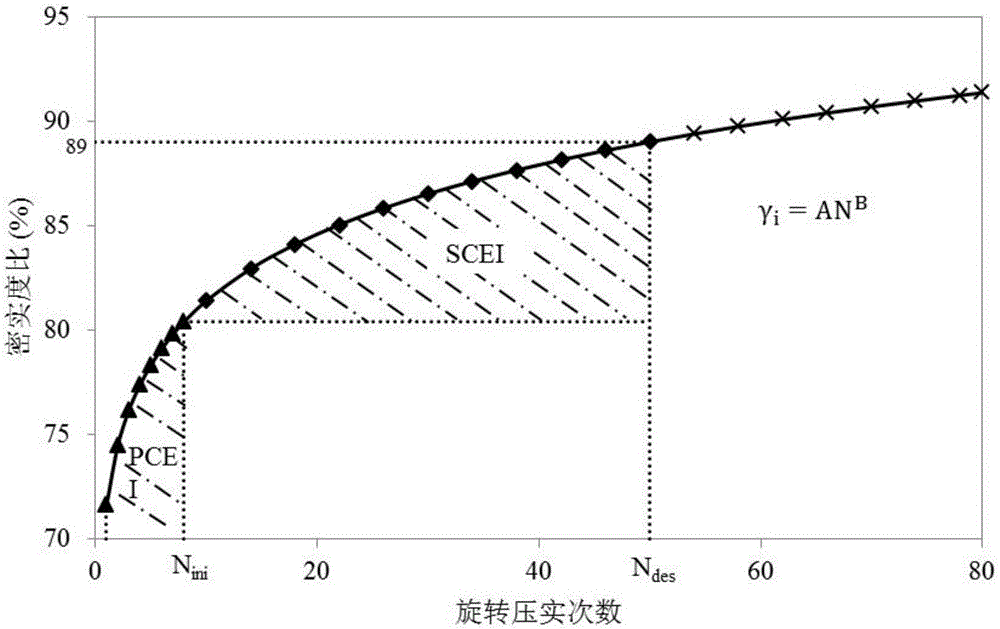

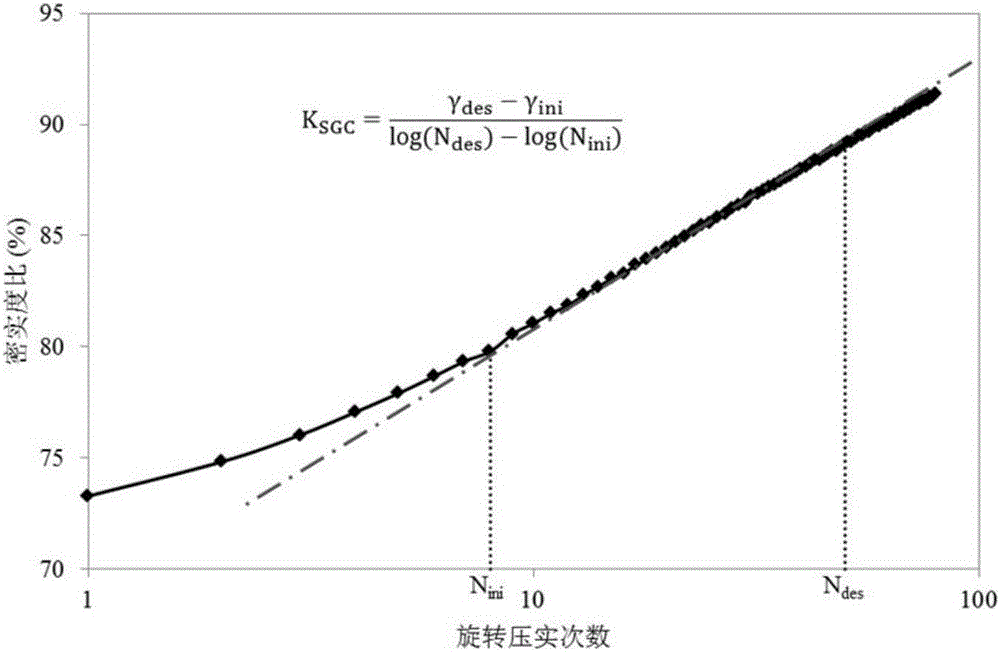

[0084]The compaction curve obtained in the rotary compaction process of the present invention is an important basis for studying the compaction characteristics of asphalt mixture. The present invention uses a rotary compactor (SGC) to carry out rotary compaction of the emulsified asphalt cold recycled mixture. According to the development trend of the compaction curve and the asymptote principle, the maximum number of rotary compaction Nmax is set to 80 times, and the maximum compaction The compaction curve after the number of times tends to a horizontal line. The ratio of the relative bulk density Gmb of the emulsified asphalt cold recycled mixture specimen after final compaction and curing to the relative maximum theoretical density Gmm is the density ratio corresponding to 80 times of rotary compaction. According to the compaction height recorded by the gyratory compactor during the compaction process, the volumetric method is used to back-calculate to obtain the density ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com