An electronic cigarette and its heating element temperature control method

A heating element and electronic cigarette technology, which is applied in the field of electronic cigarettes, can solve the problems of increasing the volume and design complexity of the internal circuit of electronic cigarettes, failing to detect the heating wire, knowing the temperature change of the heating wire, etc., to increase the volume and design complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

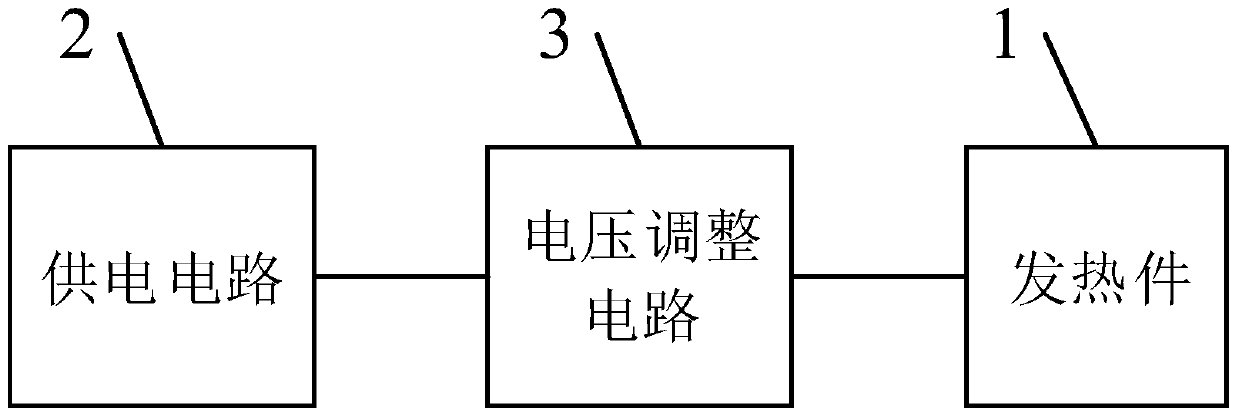

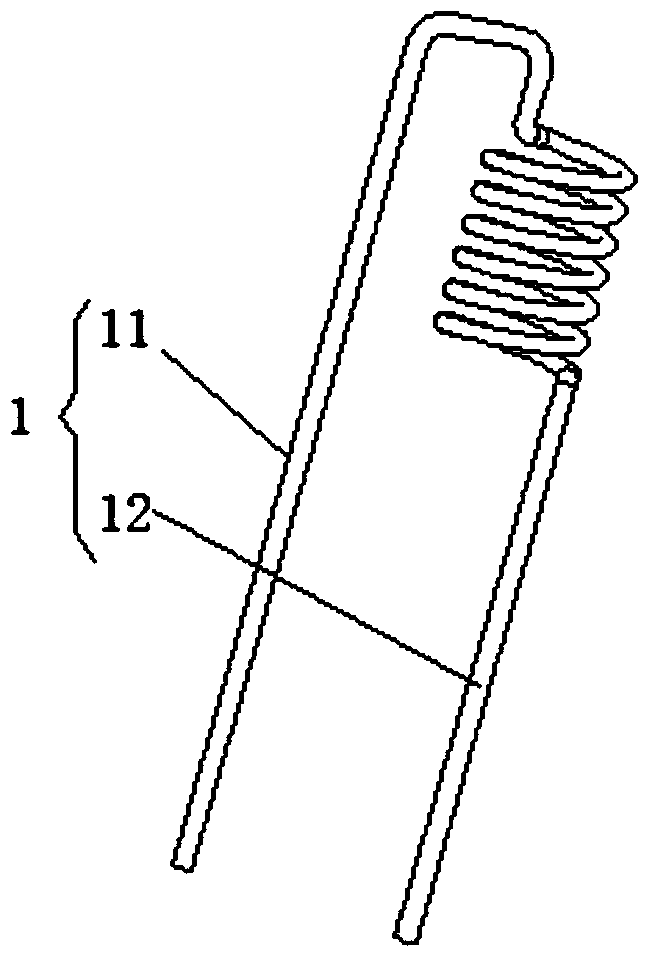

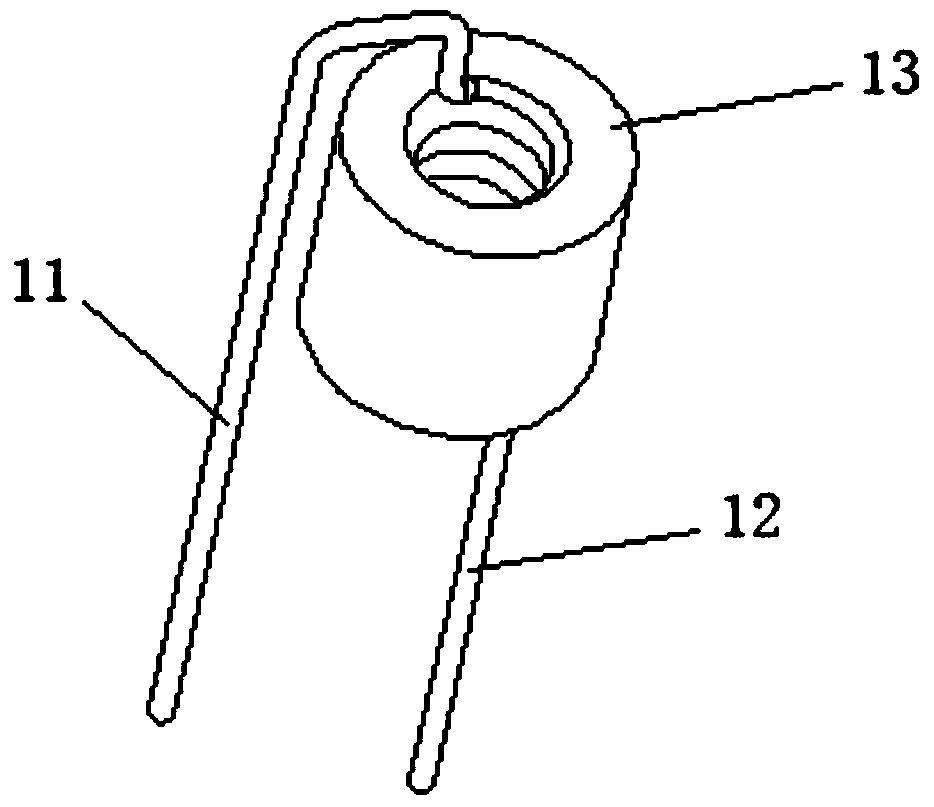

[0056] Please refer to figure 1 , the embodiment of the present invention provides an electronic cigarette, including a heating element 1, a power supply circuit 2 and a voltage adjustment circuit 3;

[0057] The heating element 1 is used to atomize the e-liquid, and the resistance value of the heating element 1 increases as the temperature increases;

[0058] The power supply circuit 2 is used to supply power to the heating element 1;

[0059] The voltage adjustment circuit 3 is used to detect the resistance value of the heating element 1 to obtain the current temperature of the heating element 1, and adjust the power supply of the heating element 1 when the current temperature is greater than the first preset value or less than the second preset value Voltage, so that the heating temperature of the heating element 1 is maintained within the preset temperature range; for example, the optimum temperature for the atomization of e-liquid is between 200°C and 270°C, when the cur...

Embodiment 2

[0078] Based on the same invention concept, please refer to Figure 7 , the embodiment of the present invention also provides a method for controlling the temperature of the heating element 1 of the electronic cigarette, comprising the steps of:

[0079] S1. Detect the resistance value of the heating element 1 to obtain the current temperature of the heating element 1 when the heating element 1 for atomizing e-liquid of the electronic cigarette is energized and working;

[0080] S2. When the current temperature is greater than a first preset value or lower than a second preset value, adjust the power supply voltage of the heating element 1 to maintain the heating temperature of the heating element 1 within a preset temperature range.

[0081] Specifically, the step S1 is specifically:

[0082] During the power-on process of the heating element 1 for atomizing e-liquid of the electronic cigarette, the current power supply voltage and current power supply current of the heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com