Automatic cord clamping device for steel cord wrapping machine

A technology of outer winding machine and steel cord, applied in the field of steel cord production, can solve the problems of increasing the amount of semi-finished products, the strong magnetic adsorption device cannot fix the cord, and the hidden danger of product quality, so as to ensure normal operation and prevent return. The effect of shrinking phenomenon and eliminating accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

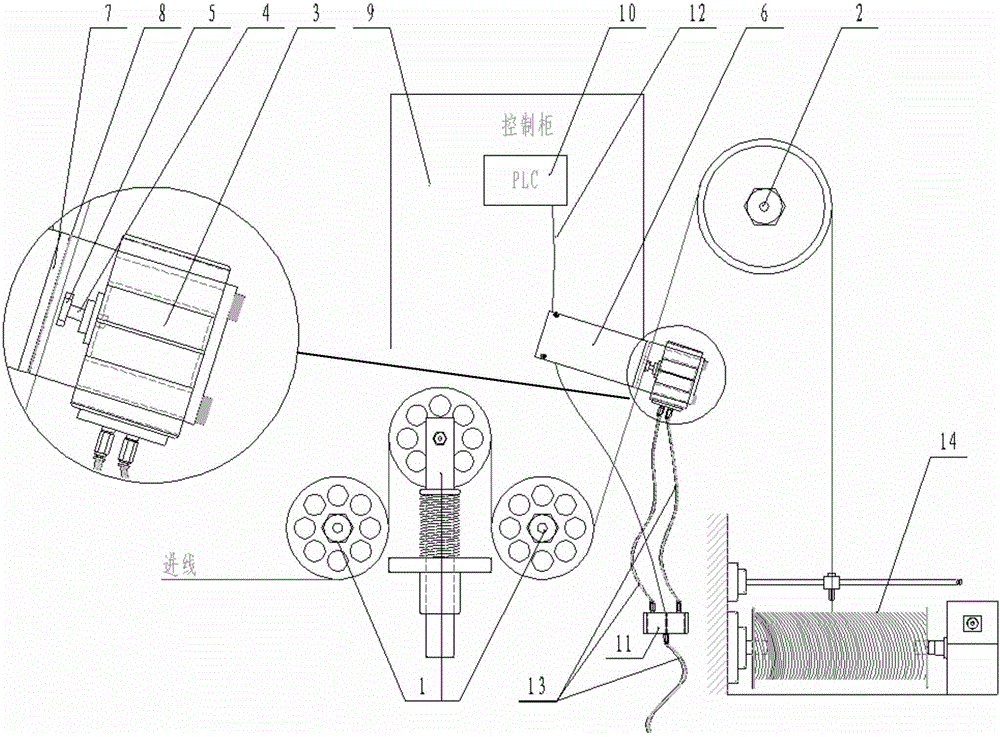

[0008] The specific structure and characteristics of the automatic wire clamping device of the steel cord outer winding machine of the present invention will be further described below with reference to the accompanying drawings.

[0009] see figure 1 A schematic diagram of the composition of an automatic wire clamping device for a steel cord outer winding machine according to an embodiment of the present invention is shown. The pneumatic wire clamping device between the force arm guide wheels 2, the pneumatic wire clamping device includes a cylinder 3, a cylinder shaft 4, a first polyurethane gasket 5, a fixing bracket 6, a baffle 7 and a second polyurethane gasket 8, so The first polyurethane gasket 5 is arranged on the cylinder shaft 4, and the second polyurethane gasket 8 is arranged on the baffle plate 7; the pneumatic thread clamping device is fixed with the outer winding machine through the fixing bracket 6; the pneumatic thread clamping device is The solenoid valve 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com