Hand-push type flat plate welding tail heat-dissipating protection device

A technology of flat plate welding and protection device, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as low efficiency and slow cooling time, and achieve the effects of compact structure, improved welding efficiency and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

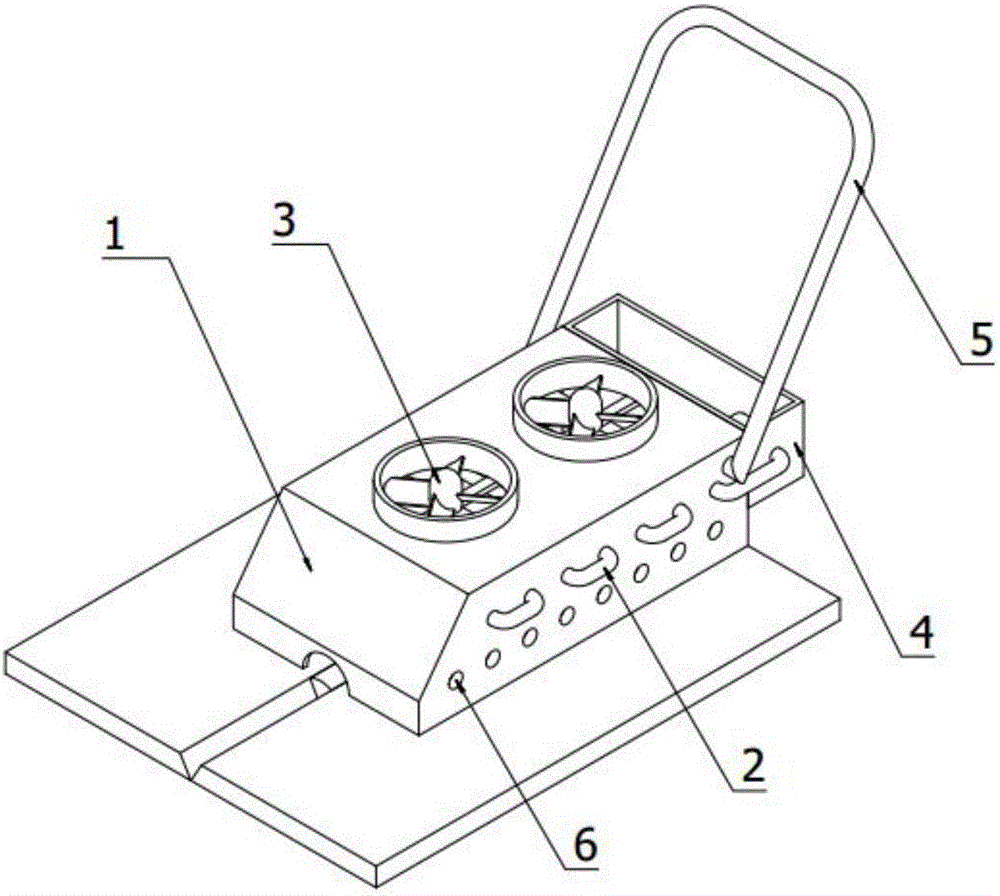

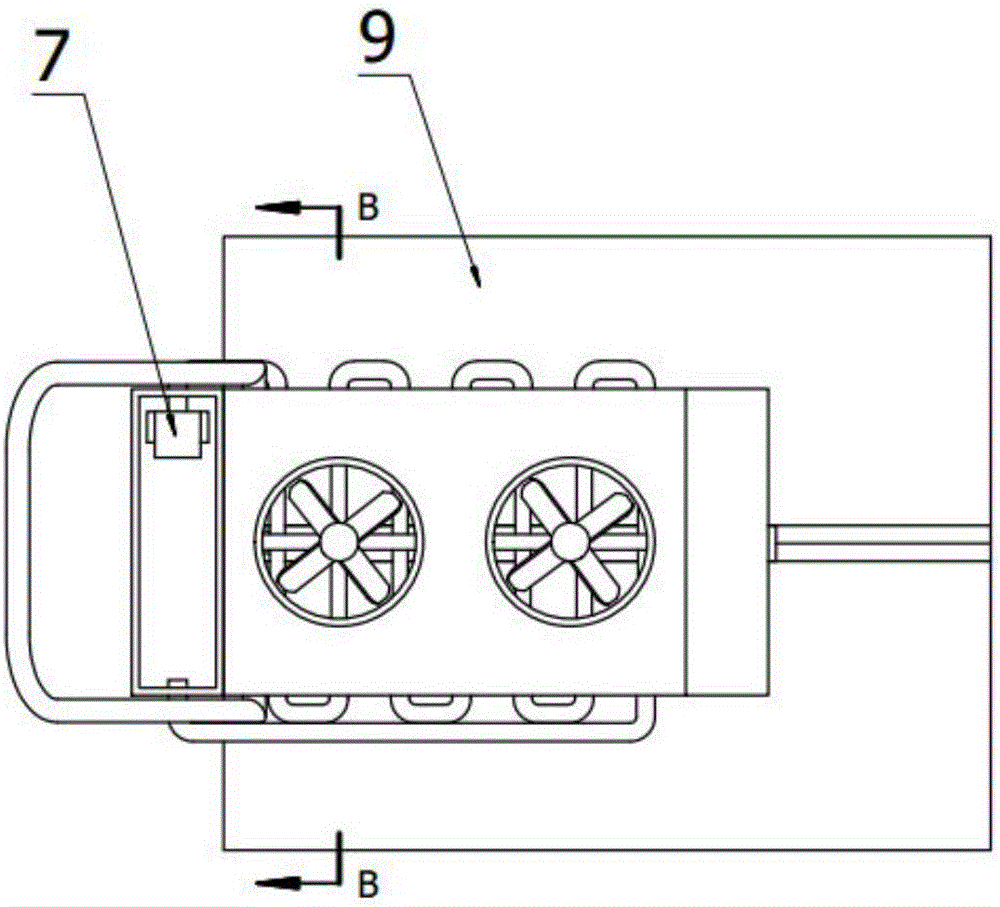

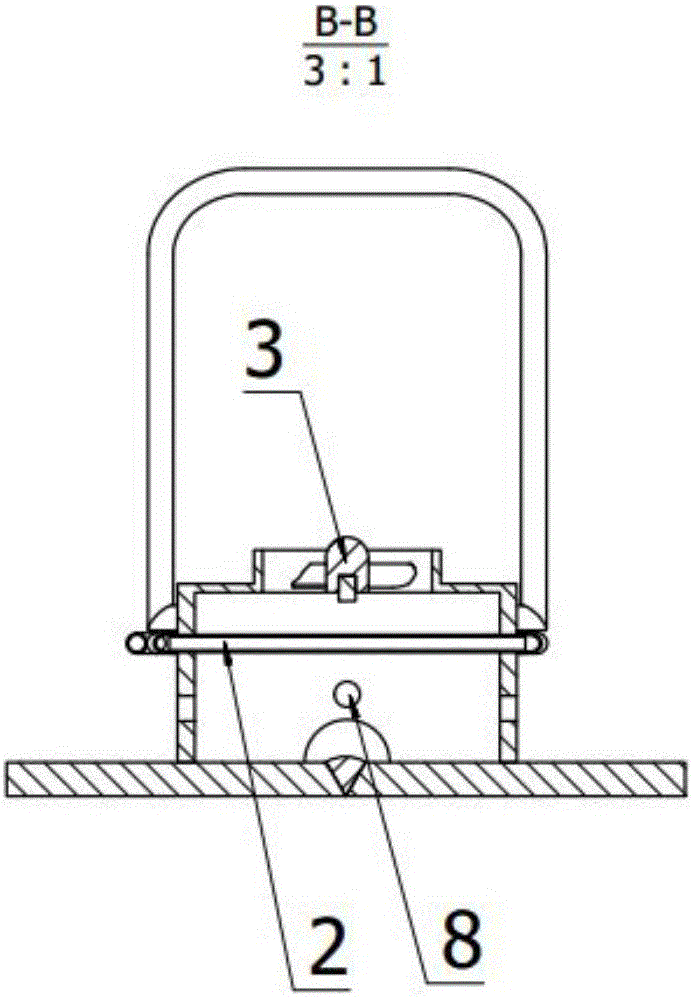

[0018] Such as figure 1 As shown in 3, a kind of hand-push type plate 9 welded tail heat dissipation protection device of the present invention includes a plate 9, a protective cover 1, a heat dissipation fan 3 and a water circulation pipeline 2, and the protective cover 1 is covered on the welded part of the plate 9. Above the seam, a number of exhaust holes are reserved on the top of the protective cover 1, and each exhaust hole is installed with a cooling fan 3 in the opposite direction. Air intake holes 6 are respectively opened on the two side walls of the protective cover 1, and the tail of the protective cover 1 is assembled. There is a water storage tank 4, the water circulation pipeline 2 is installed inside the protective cover 1, and one end of the water circulation pipeline 2 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com