A circular seam root cleaning device, root cleaning mechanism and root cleaning method

A technology of root cleaning and annular seam, which is applied to the parts of grinding machine tools, machine tools suitable for grinding the edge of workpieces, metal processing equipment, etc. The problem of low root cleaning efficiency and other problems can achieve the effect of high root cleaning efficiency, high pass rate, and improved grinding stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

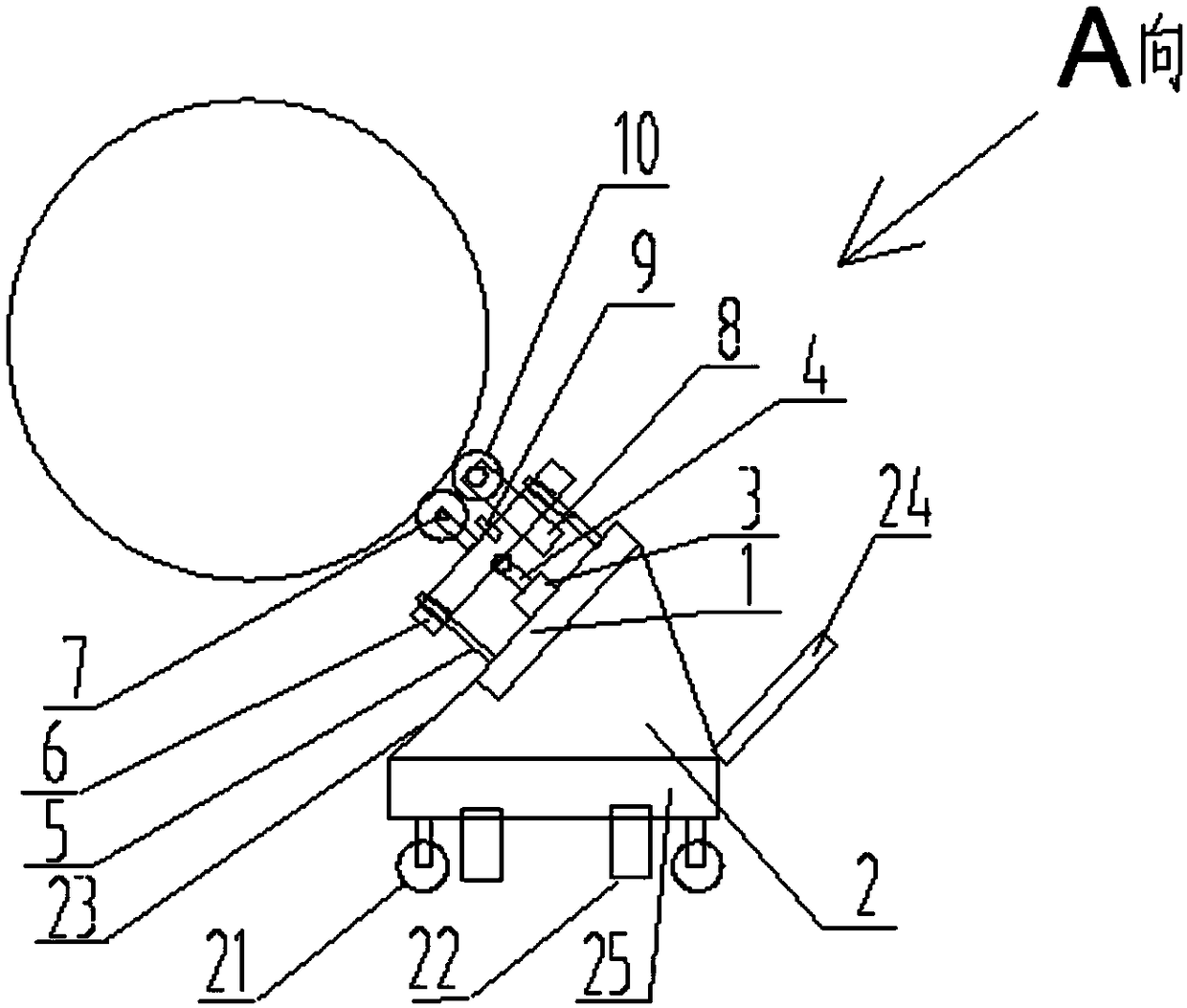

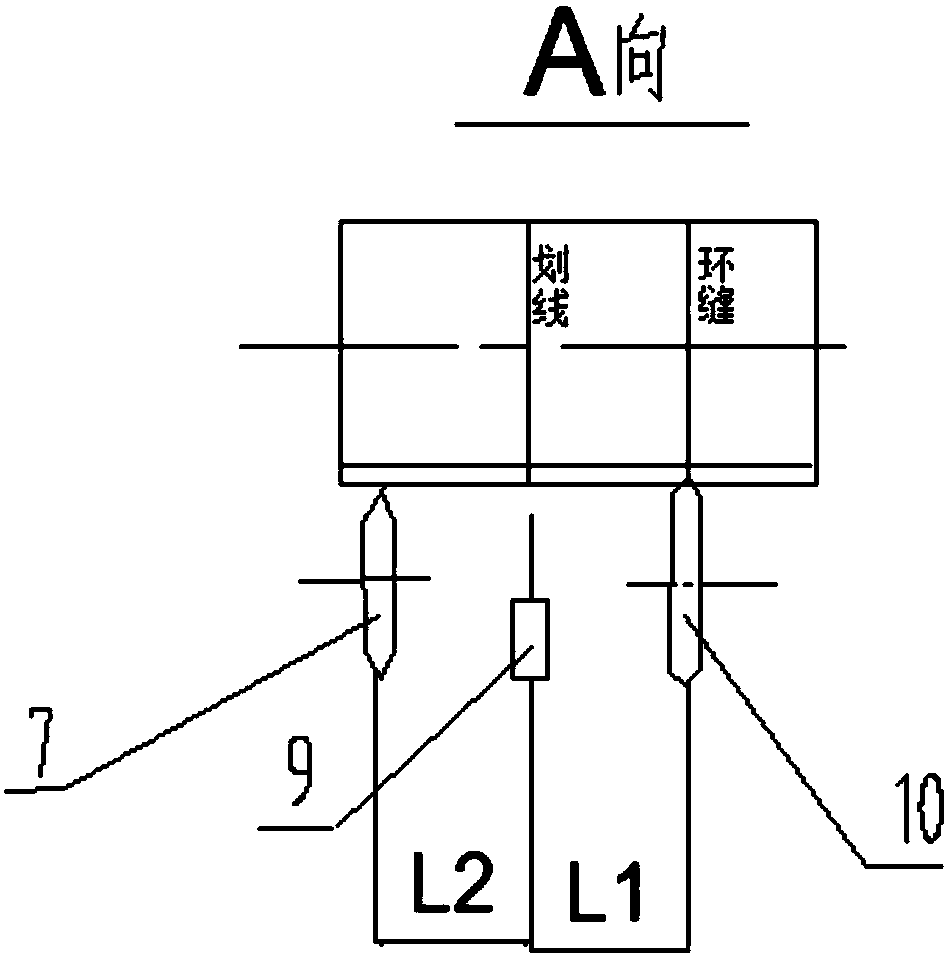

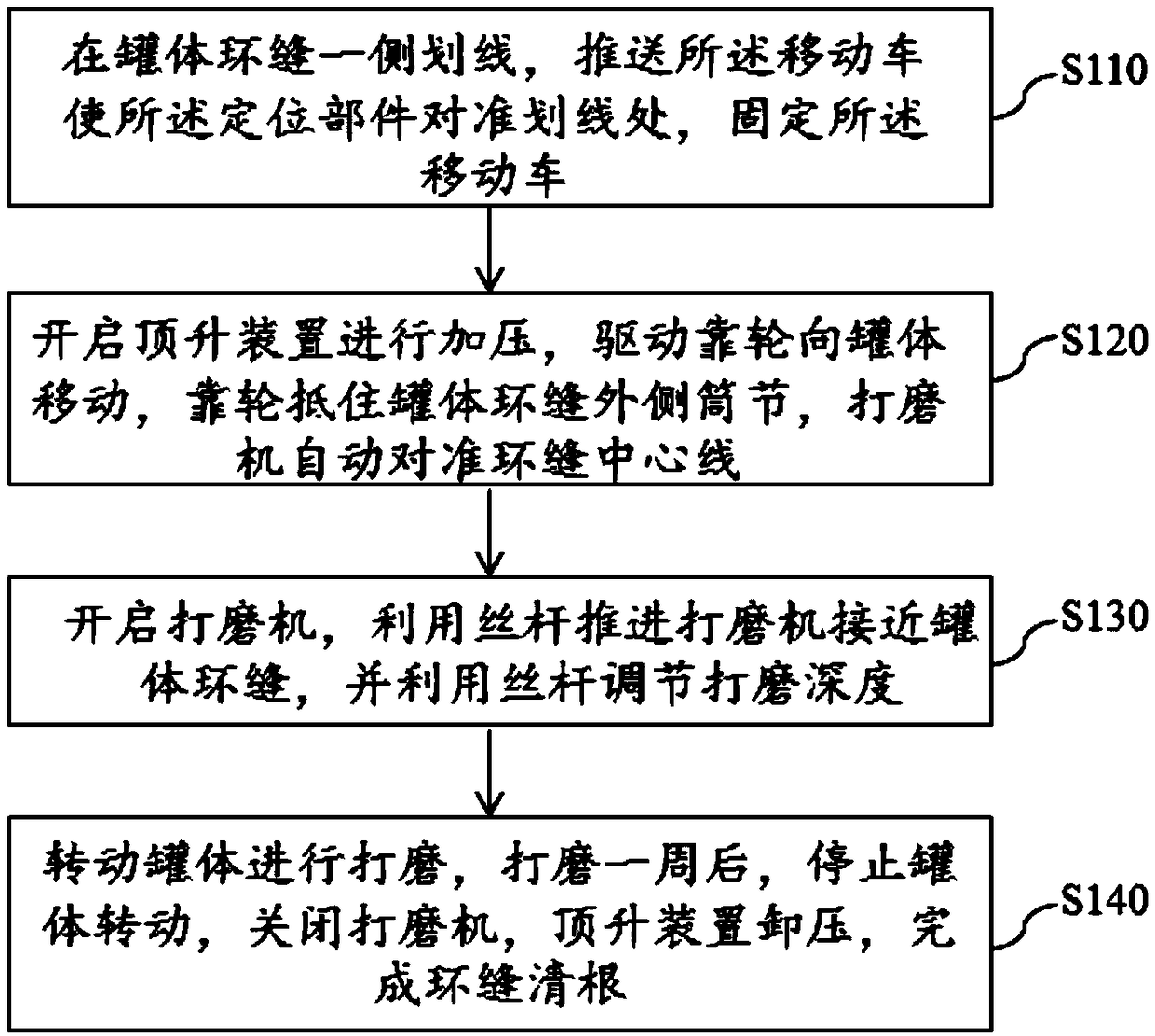

[0072] A circular seam cleaning device, used in conjunction with a roller frame, is used to clean the circular seam of a tank, such as figure 1 and figure 2 As shown, the root clearing device includes: a mobile car 2 and a root clearing mechanism obliquely fixed on the mobile car 2; the root clearing mechanism includes a fixed plate 1 obliquely fixed on the fixed slope 23 of the mobile car 2; Specifically, the angle between the fixed slope 23 and the horizontal plane is 45°, so that the root cleaning mechanism is inclined at 45° to the horizontal plane. Two slide bars 5 are fixed on the fixed plate 1, and the tops of the two slide bars 5 are connected by a support base 6, and an air cylinder 3 is also fixed on the fixed plate 1, and the air cylinder 3 has a piston rod 4, so The piston rod 4 is connected with the support base 6, and the support base 6 is connected with the roller 7; the support base 6 is provided with a laser pointer for positioning the annular seam; Connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com