Integrated garment automatic packaging machine

An automatic packaging machine and clothing technology, applied in the field of clothing processing, can solve problems such as difficulty in ensuring that clothing is controlled within the error range, reducing work efficiency, and increasing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

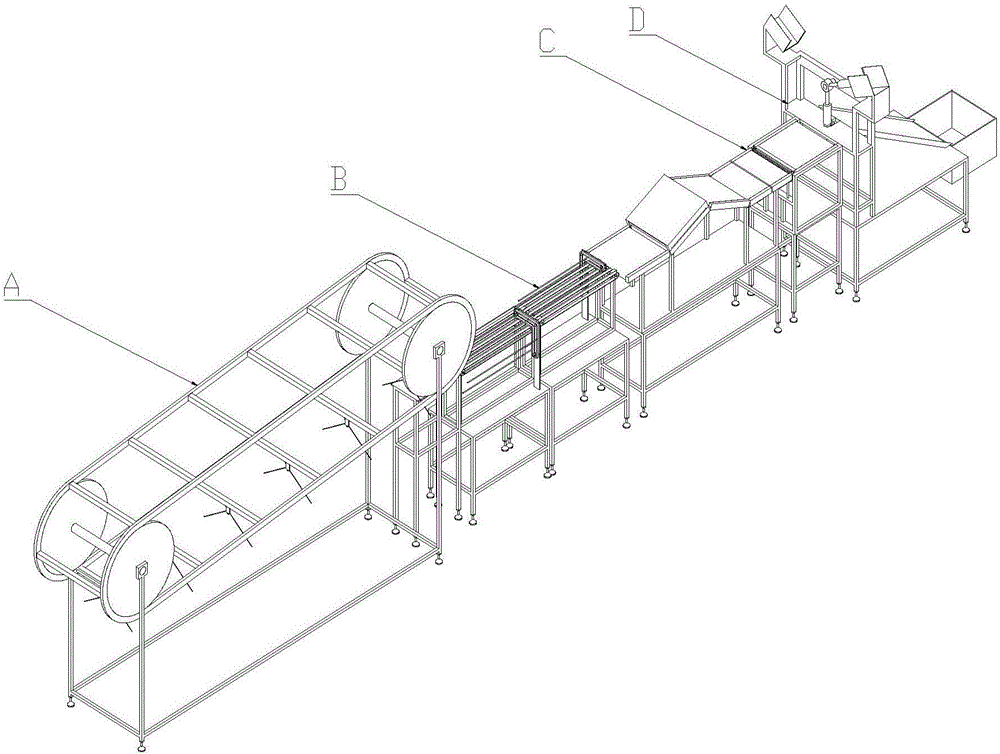

[0056] see figure 1 , the integrated automatic garment packaging machine of the present embodiment includes a frame on which an automatic clothes laying device A, a sleeve folding and ironing device B, a clothes half-folding device C and clothes Packaging device D.

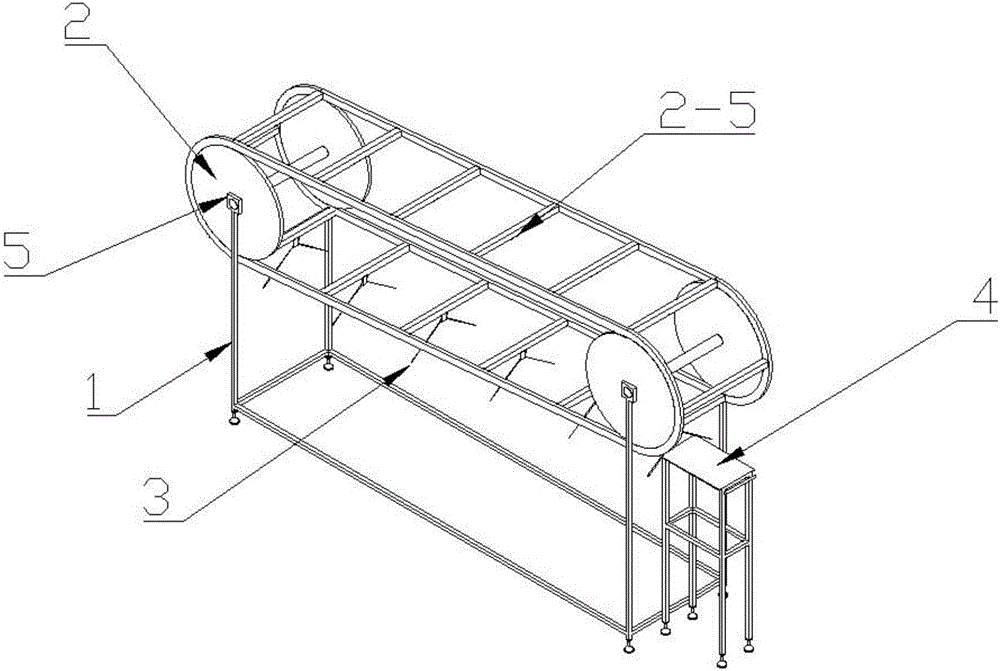

[0057] see Figure 2 ~ Figure 4 , The clothes automatic tiling device A includes a clothes conveying mechanism 2 , a conveying mechanism supporting frame 1 and a workbench 4 .

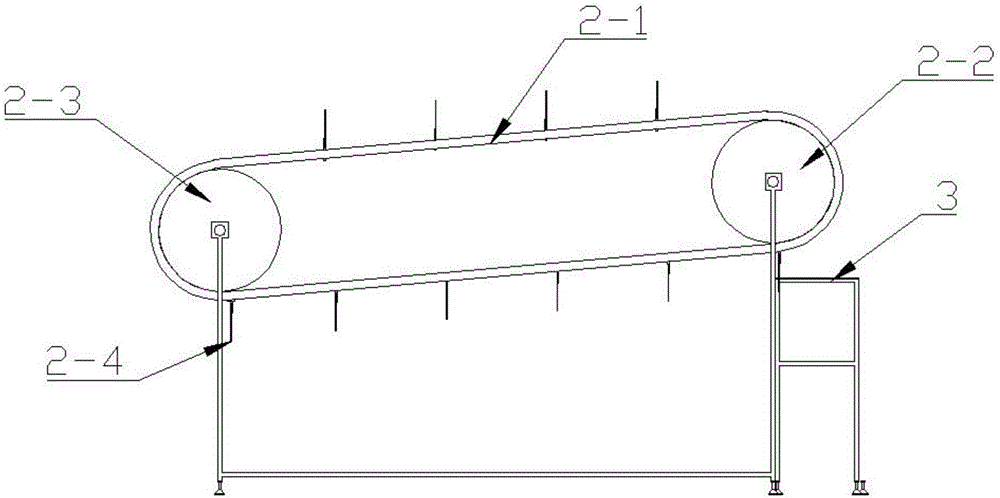

[0058] see figure 2 and image 3 The clothes conveying mechanism 2 includes a clothes support mechanism 3, a transmission belt 2-1, two sets of front and rear transmission pulleys, and a power mechanism 5 for driving the transmission pulleys, wherein the transmission belt 2-1 loops around the two sets of transmission pulleys to form a loop Closed structure, the transmission belt 2-1 is fixed with a plurality of clothing supporting mechanisms 3; the clothing supporting mechanism 3 includes a clothes hanger 2-4 and two hanging arms 3-4 ...

Embodiment 2

[0099] see Figure 5 The difference between this embodiment and Embodiment 1 is that the switching mechanism in the clothes support mechanism 3 is a four-bar linkage mechanism 3-12, and the connection between the four-bar linkage mechanism 3-12 and the hanging arm 3-7 Connected by a rotating structure 3-13, one end of the first connecting rod 3-11 is connected to the four-bar linkage mechanism 3-12 through the rotating structure 3-13, and the other end is connected to the movable rod of the cylinder 3-10. The cylinder 3-10 drives the first connecting rod 3-11 to move up and down, thereby driving the 1 hanging arm 2-5 at both ends of the clothes hanger 2-4 to open or close.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com