An intelligent cable arrangement for optical fiber stainless steel pipe production line

A stainless steel tube and production line technology, applied in thin material handling, conveying filamentous materials, transportation and packaging, etc., can solve the problems of inability to realize fully automatic wiring, damage to manufacturing optical cables, irregular wiring, etc. The effect of line uniformity and aesthetics, stable rotation speed and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

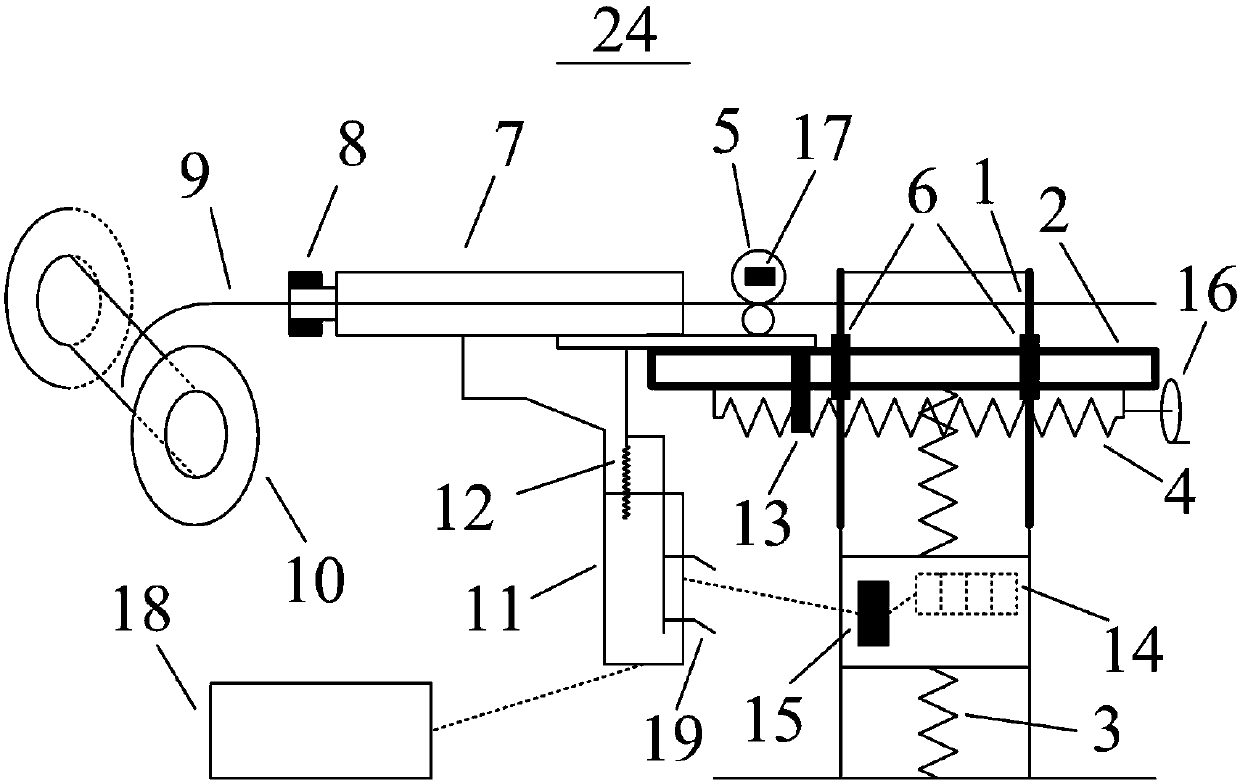

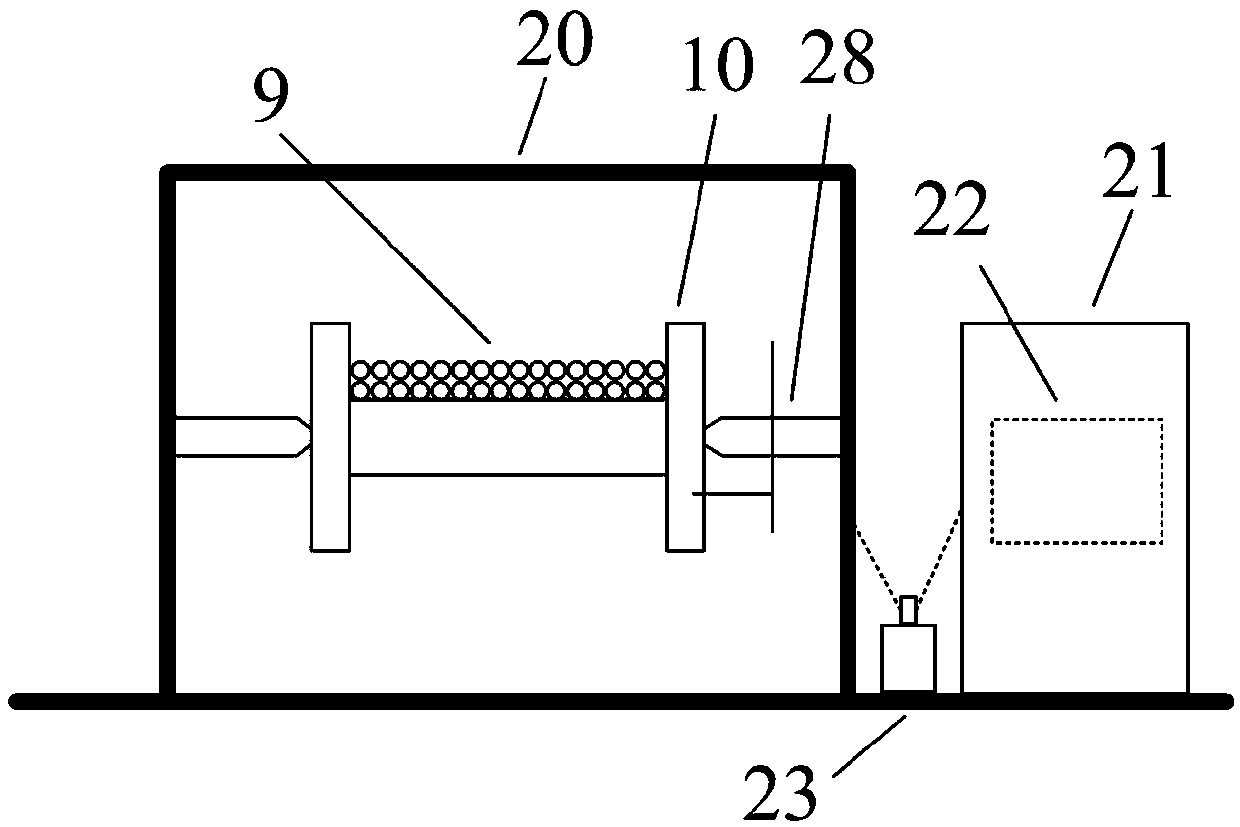

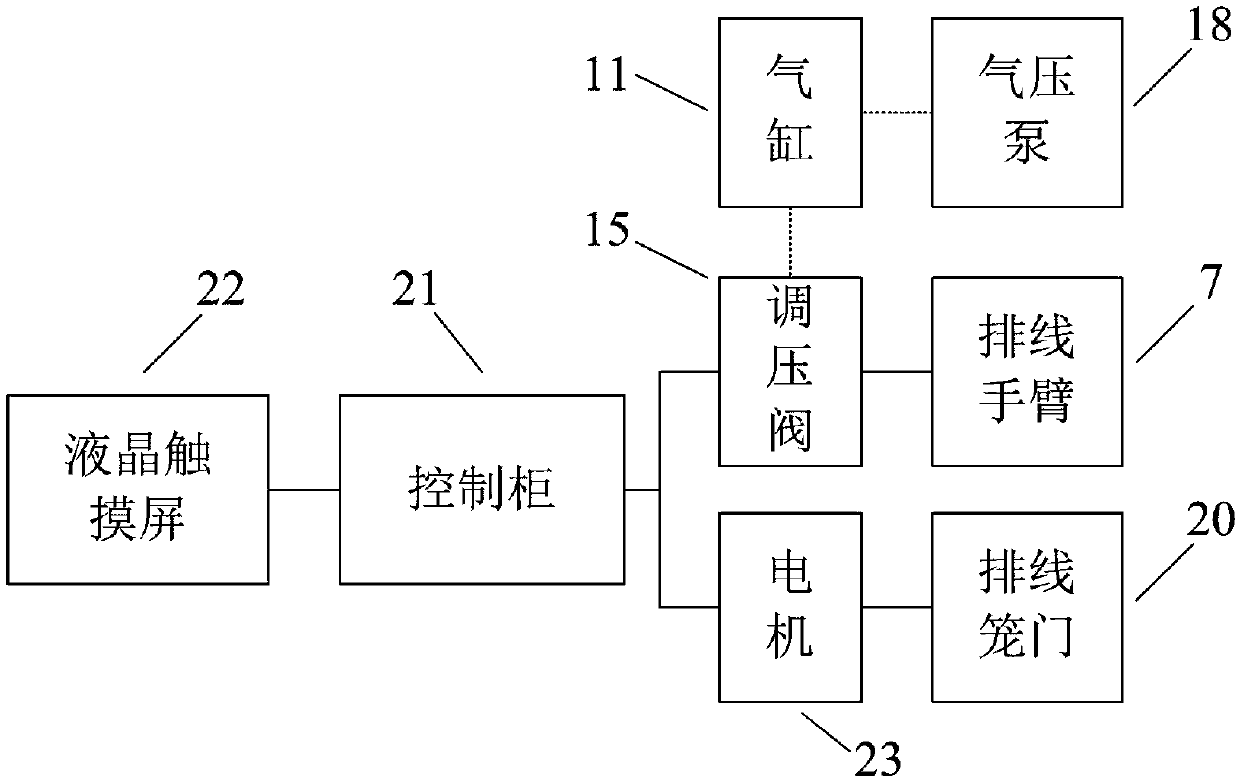

[0016] Such as Figure 1-3 As shown, an intelligent cable arrangement for an optical fiber stainless steel pipe production line includes a cable arrangement main body 24, and the cable arrangement main body 24 includes a position adjustment unit, a cable protection unit and a fully automatic cable arrangement unit; the position The adjustment unit includes a longitudinal guide rail 1, a transverse guide rail 2, a longitudinal rack 3, a transverse rack 4, a sliding gear 13, an air pressure display 14, a pressure regulating valve 15 and a lifting handle 16; The back of the guide rail 2 is connected; the top of the longitudinal rack 3 is fixedly connected to the back of the transverse guide rail 2; the transverse rack 4 is fixedly connected to the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com