Boron-free glass fiber composition and glass fibers and composite material thereof

一种纤维组合物、玻璃纤维的技术,应用在无硼玻璃纤维组合物领域,达到降低液相线温度和表面张力、降低析晶程度和气泡率、优异机械强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

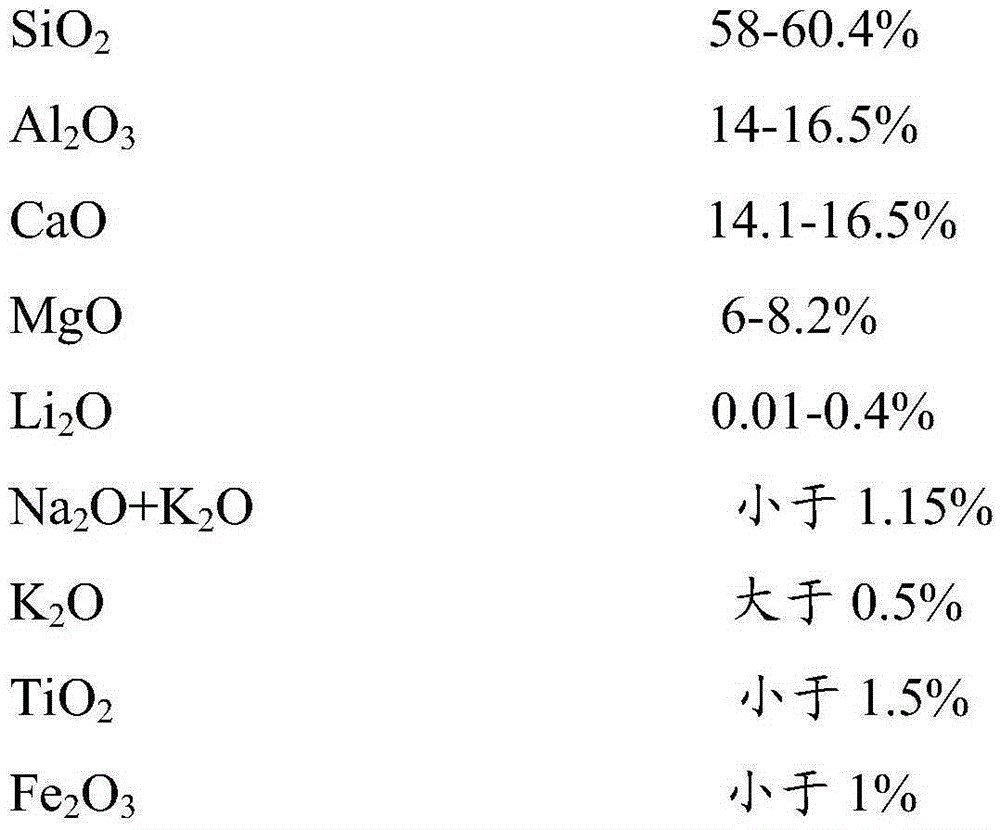

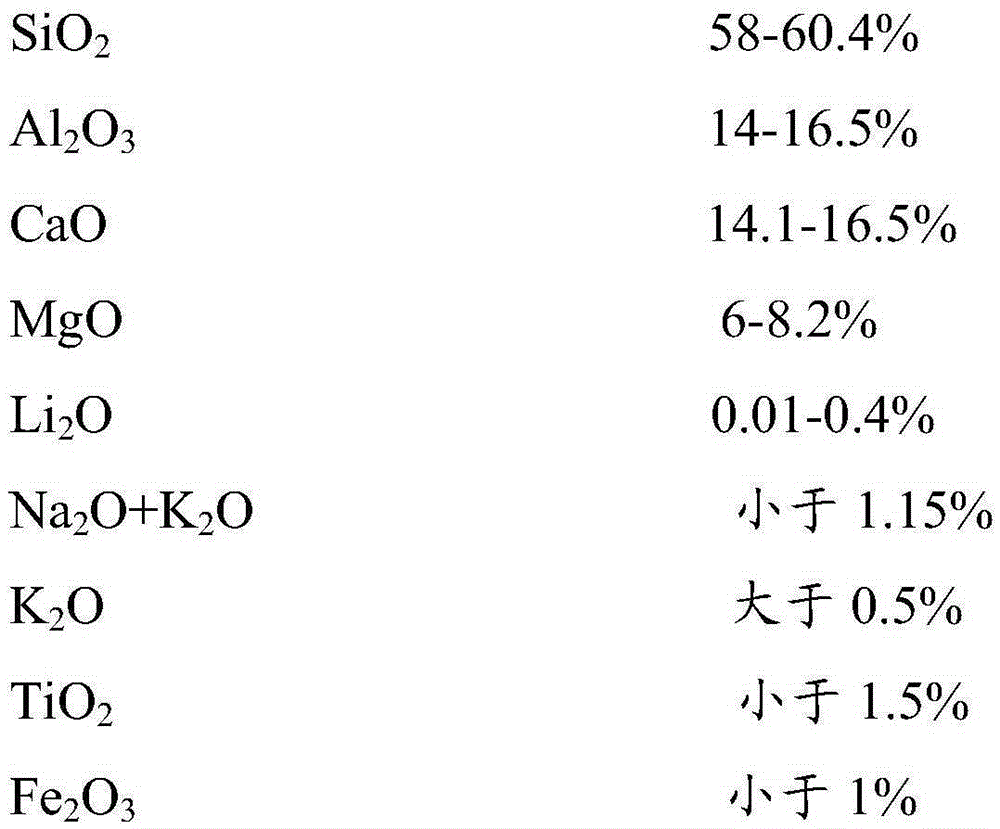

Image

Examples

Embodiment 1

[0063]

[0064]

[0065] And, the weight percent ratio C1=CaO / MgO is 2.13, and the weight percent ratio C2=K 2 O / Na 2 O is 1.49.

[0066] The numerical values of six parameters measured in embodiment one are respectively:

[0067]

Embodiment 2

[0069]

[0070] And, the weight percent ratio C1=CaO / MgO is 2.14, and the weight percent ratio C2=K 2 O / Na 2 O is 3.41.

[0071] The numerical values of six parameters measured in embodiment two are respectively:

[0072]

Embodiment 3

[0074]

[0075] And, the weight percent ratio C1=CaO / MgO is 2.20, and the weight percent ratio C2=K 2 O / Na 2 O is 4.05.

[0076] The numerical values of six parameters measured in embodiment three are respectively:

[0077]

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com