Artificial foam oil accelerator and flooding method for heavy oil reservoir after steam flooding

A technology for heavy oil reservoirs and production methods, applied in production fluids, chemical instruments and methods, earthwork drilling and production, etc., can solve problems such as high water saturation, impact of bubble performance and half-life, and insufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

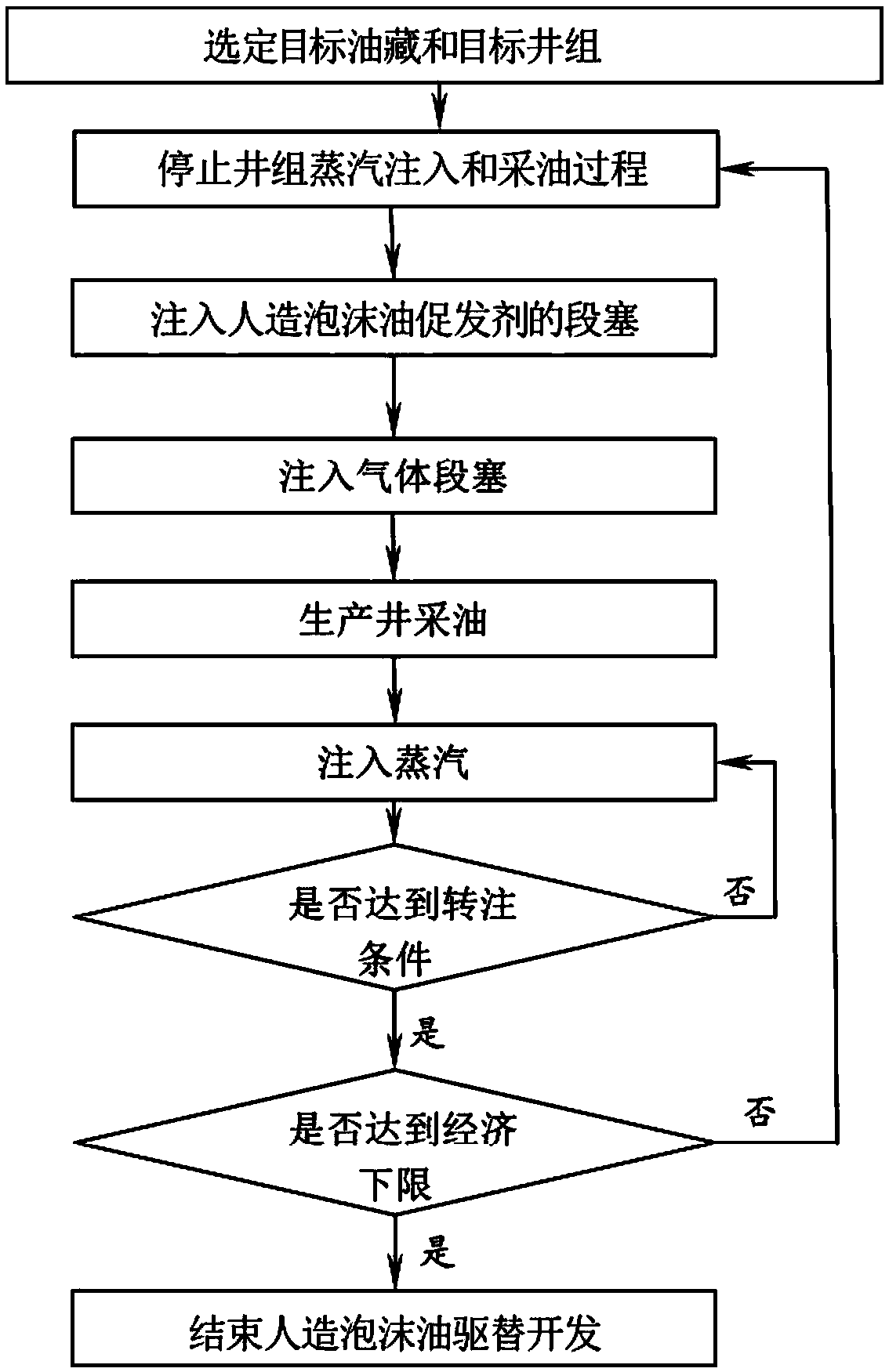

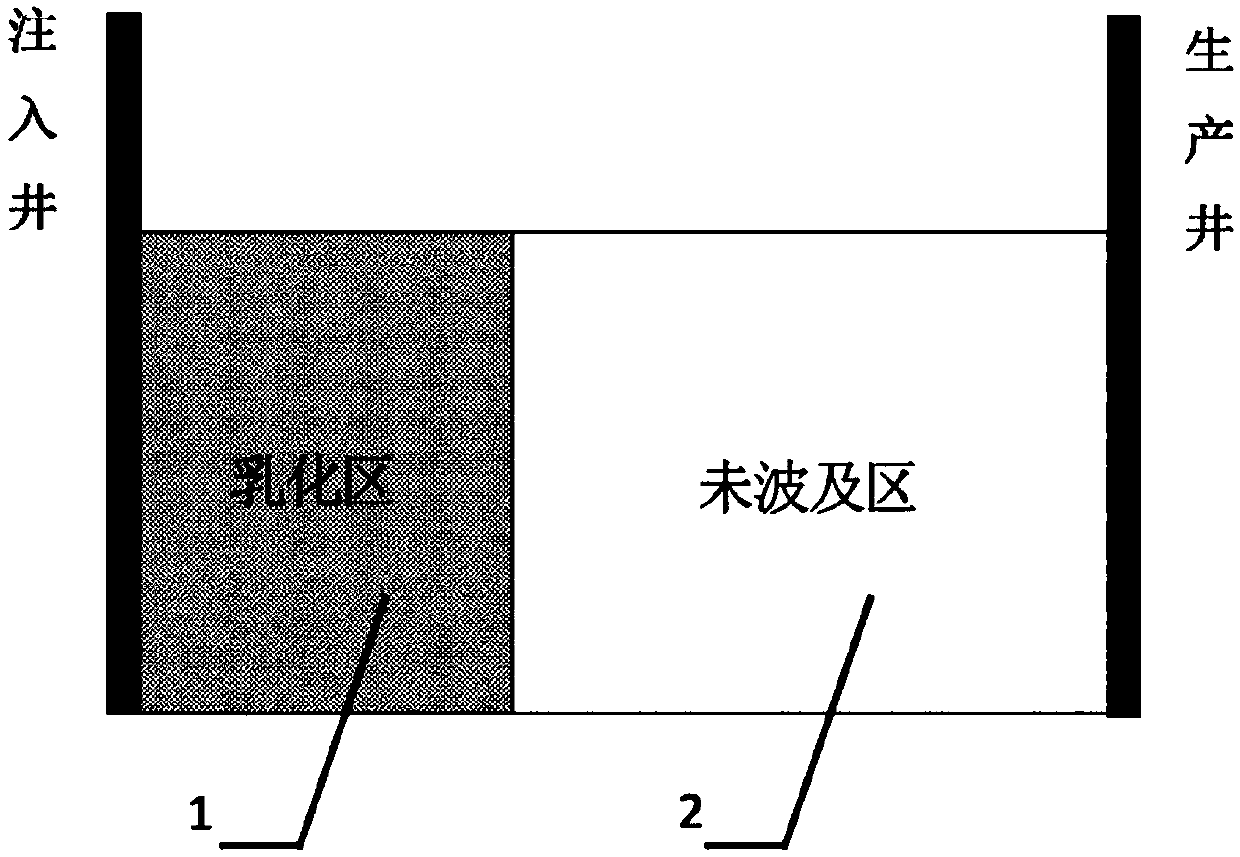

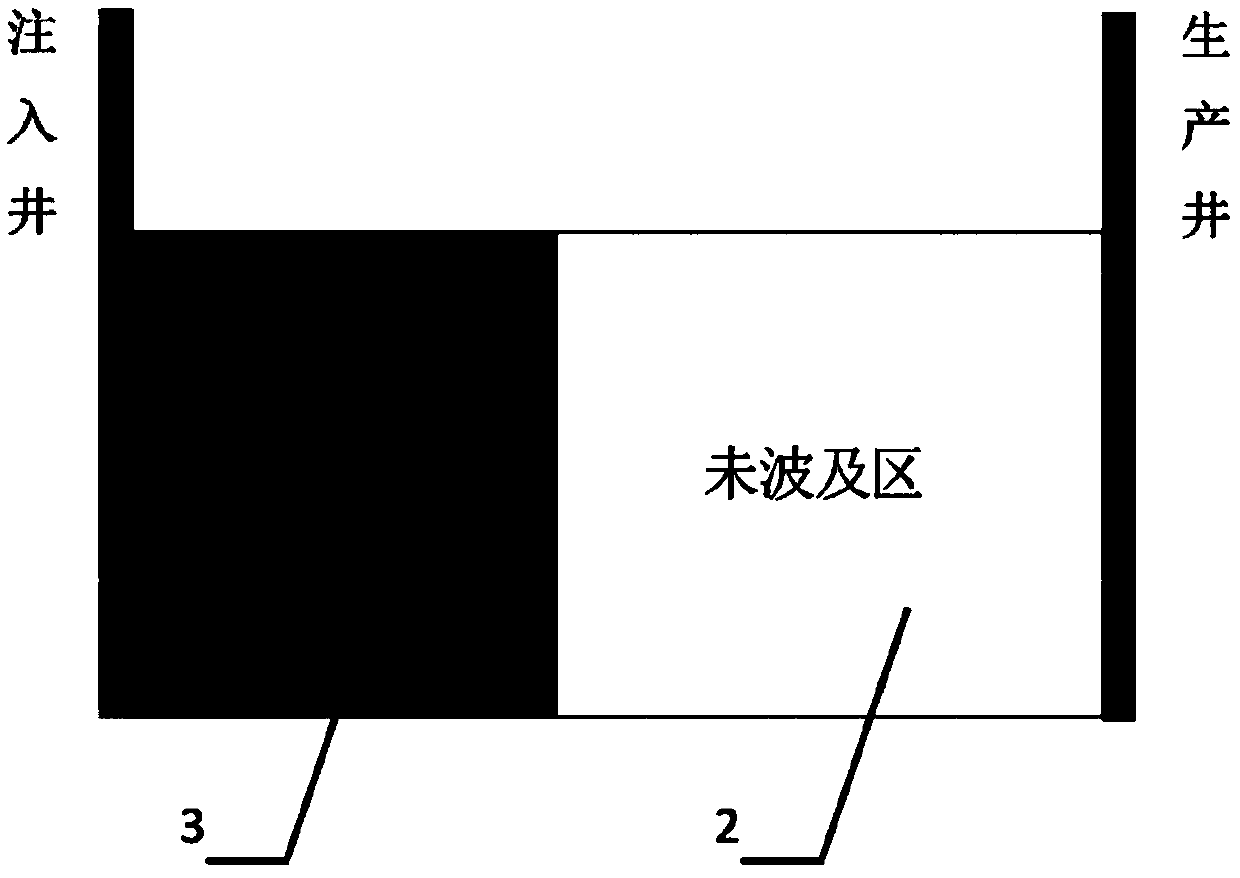

[0078] This embodiment provides a displacement recovery method for a heavy oil reservoir after steam flooding according to the present invention.

[0079] A heavy oil reservoir in eastern China is used, with a buried depth of 1550m. By the end of June 2013, the proven oil geological reserves were 87.5 million tons, and 48.12 million tons were produced, with a production rate of 55%. The thickness of the reservoir is 10m, and the formation permeability is 1500×10 -3 μm 2 , the buried depth of the formation is 700m, the original formation pressure is 6.2MPa, the original formation temperature is 40°C, the viscosity of crude oil under the formation conditions is 500mPa·s, and the initial oil saturation is 65%. The reservoir began to be developed with steam flooding technology based on steam huff and puff in June 2013. As of June 2015, the water cut of some well groups has reached over 60%.

[0080] The specific steps of the steam flooding heavy oil reservoir displacement recove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com